Iziteshi Zensimbi Engagqwali C

Incazelo emfushane:

Iziteshi zensimbi engagqwali ziyizingxenye zesakhiwo ezenziwe ngensimbi engagqwali, ingxubevange emelana nokugqwala eyakhiwe ngokuyinhloko ngensimbi, i-chromium, i-nickel, nezinye izakhi.

Iziteshi Zensimbi Engagqwali:

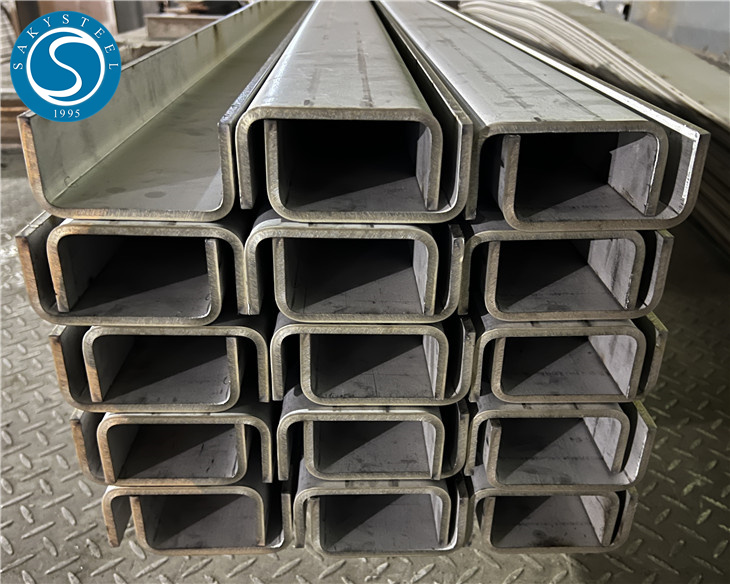

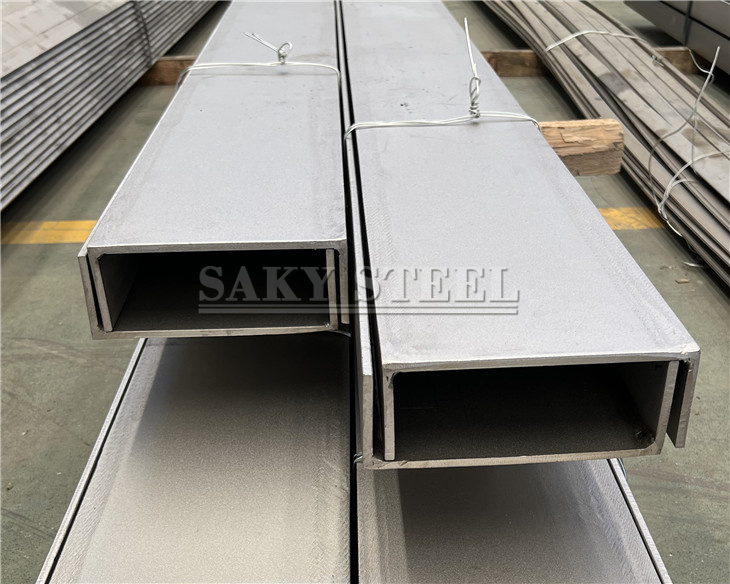

Amashaneli ensimbi engagqwali amaphrofayili esakhiwo enziwe ngama-alloys ensimbi engagqwali engagqwali, afaka ingxenye esiphambano emise okuka-C noma emise oku-U, elungele ukusetshenziswa ekwakhiweni, embonini, nasezindaweni zasolwandle. Imvamisa ikhiqizwa ngezinqubo zokugoqa okushisayo noma ezibandayo, zinikeza ukumelana nokugqwala okuhle kakhulu nokusekelwa kwesakhiwo, okusetshenziselwa kabanzi ekwakheni amafreyimu, izinto zokukhiqiza, ubunjiniyela basolwandle, nezinye izinhlelo zokusebenza ezahlukahlukene. Kuye ngokucaciswa okusungulwe ngamazinga afana ne-ASTM, EN, njll., amabanga ahlukene ensimbi engagqwali afana no-304 noma 316 angakhethwa ukuze ahlangabezane nezimfuneko ezithile zephrojekthi enikeziwe.Amashaneli ensimbi engagqwali angase abe nokuqedwa okuhlukile kwendawo, njengokupholishwa, ukubhulashwa, noma umshini wokugaya, kuye ngesicelo esihlosiwe kanye nezidingo zobuhle.

Imininingwane Yebha Yeziteshi:

| Ibanga | 302 304 304L 310 316 316L 321 2205 2507 njll. |

| Okujwayelekile | I-ASTM A240 |

| Ubuso | Ifakwe emanzini anosawoti ashisayo, apholile |

| Uhlobo | Isiteshi se-U / Isiteshi C |

| Ubuchwepheshe | Ishisiwe, ishiselwe, iyagoba |

| Ubude | 1 kuya ku-12 Amamitha |

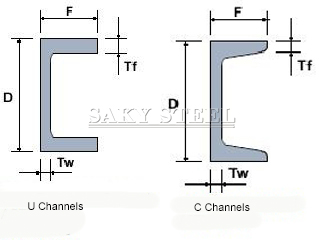

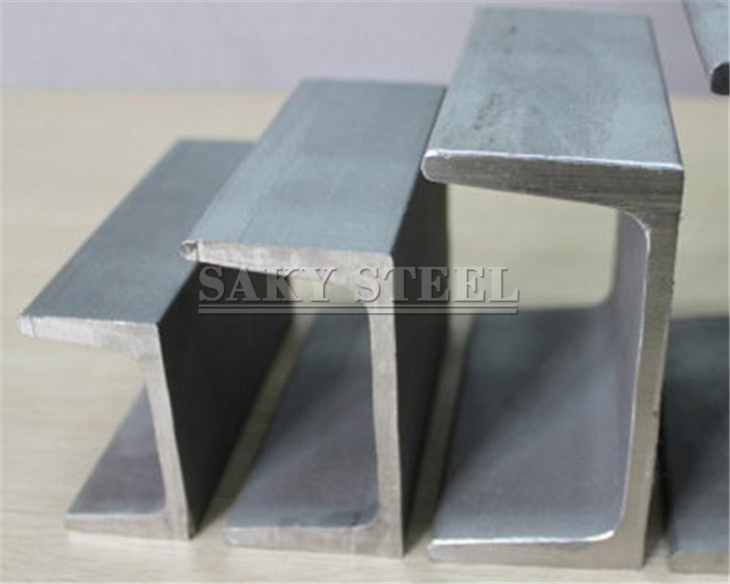

Iziteshi ze-C:Lawa anesiphambano esimise okuka-C futhi ajwayele ukusetshenziselwa izinhlelo zokusebenza zesakhiwo.

Iziteshi ze-U:Lezi zine-cross-section emise okuka-U futhi zilungele izinhlelo zokusebenza lapho i-flange engezansi idinga ukuxhunywa endaweni engaphezulu.

Izinhlobo Zebha Yeziteshi:

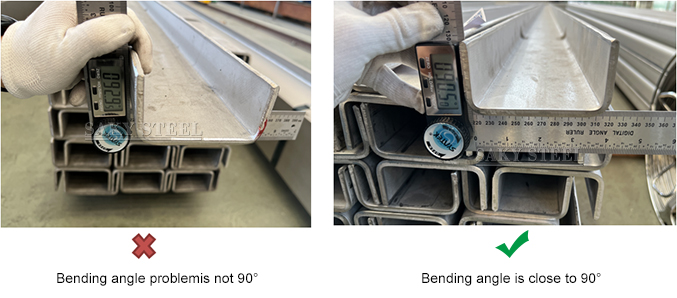

I-Stainless Steel Bend Channel Straightness:

I-engeli yesiteshi egobayo ingalawulwa ngo-89 kuya ku-91°.

Usayizi Weziteshi Ezigoqiwe Ezishisayo:

| C Amashaneli | ISISINDO kg / m | DIMENSIONS | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | ||||||||||||||||||||||

| (mm) | (cm2) | (cm3) | ||||||||||||||||||||||||

| h | b | s | t | F | Wx | Wy | ||||||||||||||||||||

| 30 x15 | 1.740 | 30 | 15 | 4.0 | 4.5 | 2.21 | 1.69 | 0.39 | ||||||||||||||||||

| 40 x20 | 2.870 | 40 | 20 | 5.0 | 5.5 | 3.66 | 3.79 | 0.86 | ||||||||||||||||||

| 40 x35 | 4.870 | 40 | 35 | 5.0 | 7.0 | 6.21 | 7.05 | 3.08 | ||||||||||||||||||

| 50 x25 | 3.860 | 50 | 25 | 5.0 | 6.0 | 4.92 | 6.73 | 1.48 | ||||||||||||||||||

| 50 x38 | 5.590 | 50 | 38 | 5.0 | 7.0 | 7.12 | 10.60 | 3.75 | ||||||||||||||||||

| 60 x30 | 5.070 | 60 | 30 | 6.0 | 6.0 | 6.46 | 10.50 | 2.16 | ||||||||||||||||||

| 65 x42 | 7.090 | 65 | 42 | 5.5 | 7.5 | 9.03 | 17.70 | 5.07 | ||||||||||||||||||

| 80 | 8.640 | 80 | 45 | 6.0 | 8.0 | 11.00 | 26.50 | 6.36 | ||||||||||||||||||

| 100 | 10.600 | 100 | 50 | 6.0 | 8.5 | 13.50 | 41.20 | 8.49 | ||||||||||||||||||

| 120 | 13.400 | 120 | 55 | 7.0 | 9.0 | 17.00 | 60.70 | 11.10 | ||||||||||||||||||

| 140 | 16.000 | 140 | 60 | 7.0 | 10.0 | 20.40 | 86.40 | 14.80 | ||||||||||||||||||

| 160 | 18.800 | 160 | 65 | 7.5 | 10.5 | 24.00 | 116.00 | 18.30 | ||||||||||||||||||

| 180 | 22.000 | 180 | 70 | 8.0 | 11.0 | 28.00 | 150.00 | 22.40 | ||||||||||||||||||

| 200 | 25.300 | 200 | 75 | 8.5 | 11.5 | 32.20 | 191.00 | 27.00 | ||||||||||||||||||

| 220 | 29.400 | 220 | 80 | 9.0 | 12.5 | 37.40 | 245.00 | 33.60 | ||||||||||||||||||

| 240 | 33.200 | 240 | 85 | 9.5 | 13.0 | 42.30 | 300.00 | 39.60 | ||||||||||||||||||

| 260 | 37.900 | 260 | 90 | 10.0 | 14.0 | 48.30 | 371.00 | 47.70 | ||||||||||||||||||

| 280 | 41.800 | 280 | 95 | 10.0 | 15.0 | 53.30 | 448.00 | 57.20 | ||||||||||||||||||

| 300 | 46.200 | 300 | 100 | 10.0 | 16.0 | 58.80 | 535.00 | 67.80 | ||||||||||||||||||

| 320 | 59.500 | 320 | 100 | 14.0 | 17.5 | 75.80 | 679.00 | 80.60 | ||||||||||||||||||

| 350 | 60.600 | 350 | 100 | 14.0 | 16.0 | 77.30 | 734.00 | 75.00 | ||||||||||||||||||

| 400 | 71.800 | 400 | 110 | 14.0 | 18.0 | 91.50 | 1020.00 | 102.00 | ||||||||||||||||||

Izici Nezinzuzo:

•Amashaneli ensimbi engagqwali amelana kakhulu nokugqwala, okuwenza afanelekele ukusetshenziswa ezindaweni ezihlukahlukene, kuhlanganise nalawo anokuchayeka kumswakama, amakhemikhali, nezimo zezulu ezinzima.

•Ukubukeka okupholishiwe nokuchachambile kwamashaneli ensimbi engagqwali kungeza ukuthinta kobuhle ezakhiweni, kuzenze zifanelekele izinhlelo zokusebenza zezakhiwo nezokuhlobisa.

•Kutholakala ngezindlela ezihlukahlukene, kuhlanganise namashaneli angu-C namashaneli angu-U, iziteshi zensimbi engagqwali zinikeza ukuguquguquka kokuklama futhi zingalungiselelwa ukuze zivumelane nezidingo ezithile zephrojekthi.

•Amashaneli ensimbi engagqwali anempilo ende yesevisi, enikeza ukuqina okunwetshiwe futhi enciphisa isidingo sokushintshwa njalo

•Amashaneli ensimbi engagqwali amelana nokulimala okuvela kumakhemikhali ahlukahlukene, okuwenza afanelekele ukusetshenziswa ezimeni zezimboni lapho ukuchayeka ezinto ezonakalisayo kuvame.

•Iziteshi zensimbi engagqwali zingashintshwa kalula kuzinhlelo zokusebenza ezihlukene, okuvumela ukuguquguquka kwemiklamo yokwakha kanye nokwakhiwa.

Iziteshi Zokwakhiwa Kwamakhemikhali C:

| Ibanga | C | Mn | P | S | Si | Cr | Ni | Mo | I-nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 0.75 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.07 | 2.0 | 0.045 | 0.030 | 0.75 | 17.5-19.5 | 8.0-10.5 | - | 0.10 |

| 304L | 0.030 | 2.0 | 0.045 | 0.030 | 0.75 | 17.5-19.5 | 8.0-12.0 | - | 0.10 |

| 310S | 0.08 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 316L | 0.030 | 2.0 | 0.045 | 0.030 | 0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 0.75 | 17.0-19.0 | 9.0-12.0 | - | - |

Izakhiwo zemishini Yeziteshi ze-U:

| Ibanga | I-Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 75[515] | 30[205] | 40 |

| 304L | 70[485] | 25[170] | 40 |

| 310S | 75[515] | 30[205] | 40 |

| 316 | 75[515] | 30[205] | 40 |

| 316L | 70[485] | 25[170] | 40 |

| 321 | 75[515] | 30[205] | 40 |

Ungagoba kanjani isiteshi sensimbi engagqwali?

Ukugoba iziteshi zensimbi engagqwali kudinga ukusetshenziswa kwamathuluzi nezindlela ezifanele. Qala ngokumaka izindawo zokugoba esiteshini futhi usivikele ngokuqinile emshinini ogobayo noma cindezela ibhuleki. Lungisa izilungiselelo zomshini, yenza ukugoba kokuhlola ukuze uqinisekise ukunemba, futhi uqhubeke nokugoba kwangempela, uqaphe ngokucophelela inqubo futhi uhlole i-engeli yokugoba. Phinda inqubo yamaphoyinti amaningi okugoba, yenza noma ikuphi ukuthinta okudingekayo kokuqeda njengokususa ibhali, futhi unamathele kuzinkombandlela zokuphepha ngokugqoka okokuvikela okufanele kuyo yonke inqubo.

Yiziphi izinhlelo zokusebenza zesiteshi sensimbi engagqwali?

Insimbi yesiteshi iwumsebenzi wesakhiwo oguquguqukayo osetshenziswa kabanzi ekwakheni, ekukhiqizeni, ezimoto, ezasolwandle, ezamandla, ekudlulisweni kwamandla, kwezokuthutha, nasekukhiqizweni kwefenisha. Ukwakheka kwayo okuhlukile, kuhlanganiswe namandla aphakeme nokumelana nokugqwala, kuyenza ibe ukukhetha okuhle ekwakheni izinhlaka, izinhlaka zokusekela, imishini, i-chassis yezimoto, ingqalasizinda yamandla kanye nefenisha. Insimbi yensimbi engagqwali ivame ukusetshenziswa emikhakheni yamakhemikhali neyezimboni ukuze kusetshenziswe izisekelo zemishini yokukhiqiza nabakaki bamapayipi, okugqamisa ukubaluleka kwayo kuzo zonke izimboni ezihlukahlukene.

Yiziphi izinkinga nge-engeli yokugoba yesiteshi?

Izinkinga ezine-engeli egobayo yamashaneli ensimbi engagqwali zingase zihlanganisa ukungalungi, ukugoba okungalingani, ukuhlanekezelwa kwempahla, ukuqhekeka noma ukuphuka, i-springback, ukuguga kwamathuluzi, ukungapheleli kwendawo, ukuqina komsebenzi, kanye nokungcoliswa kwamathuluzi. Lezi zinkinga zingavela ezicini ezifana nezilungiselelo zomshini ezingalungile, ukuhluka kwezinto ezibonakalayo, amandla amakhulu, noma ukugcinwa kwamathuluzi okwanele. Ukuze kubhekwane nalezi zinkinga, kubalulekile ukunamathela ezinqubweni zokugoba ezifanele, ukusebenzisa amathuluzi afanele, ukugcina amathuluzi njalo, nokuqinisekisa ukuthi inqubo yokugoba ihambisana namazinga omkhakha, kuncishiswe ubungozi bokubeka engcupheni ikhwalithi, ukunemba, kanye nobuqotho besakhiwo samashaneli ensimbi engagqwali.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS, TUV, BV 3.2.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Ukupakisha Iziteshi Zensimbi Engagqwali C:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho izimpahla zidlula eziteshini ezihlukahlukene ukuze zifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,