Isigaba Esingenalutho

Incazelo emfushane:

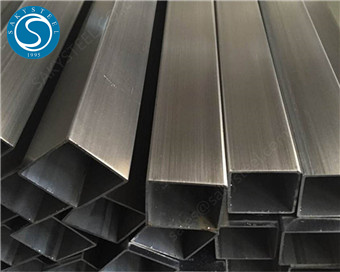

Isigaba esiyisikwele esingenalutho (SHS) sibhekisela ohlotsheni lwephrofayela yensimbi enesiqephu esiyisikwele esiyisikwele futhi esingenalutho ngaphakathi. Ivamise ukusetshenziswa ezimbonini zokwakha nezokukhiqiza ukuze kusetshenziswe izinto ezahlukahlukene ngenxa yezakhiwo zayo nezakhiwo zobuhle.

Isigaba Sesakhiwo Esingenalutho:

Ingxenye engenalutho ibhekisela kuphrofayela yensimbi enomgogodla ongenalutho futhi ivame ukusetshenziswa ezinhlelweni ezihlukahlukene zesakhiwo nobunjiniyela. Igama elithi "isigaba esingenalutho" liwumkhakha obanzi ohlanganisa umumo ohlukahlukene, okuhlanganisa isikwele, unxande, isiyingi, nezinye izimo ezingokwezifiso. Lezi zingxenye ziklanyelwe ukunikeza amandla esakhiwo nokuzinza kuyilapho ngokuvamile kunciphisa isisindo.Izingxenye ezingenalutho ngokuvamile zenziwe ngezinsimbi ezifana nensimbi, i-aluminium, noma ezinye izinto ezixubile.Ukukhethwa kwezinto kuncike ezintweni ezifana nezidingo zamandla, ukumelana nokugqwala, kanye nokusetshenziswa okuhlosiwe.

Imininingwane yesigaba esingenalutho sensimbi:

| Ibanga | 302,304,316,430 |

| Okujwayelekile | I-ASTM A312, ASTM A213 |

| Ubuso | hot rolled pickled , pholishiwe |

| Ubuchwepheshe | Ishisiwe, Eshiselwe, Ebandayo Edwetshiwe |

| Out Diameter | 1/8″~32″,6mm~830mm |

| Uhlobo | I-Square Hollow Section (SHS),Ingxenye Eyigodi EyiRectangular (RHS),Isigaba Esiyindilinga Esiyigodi (CHS) |

| I-Raw Materail | I-POSCO, i-Baosteel, i-TISCO, i-Saky Steel, i-Outokumpu |

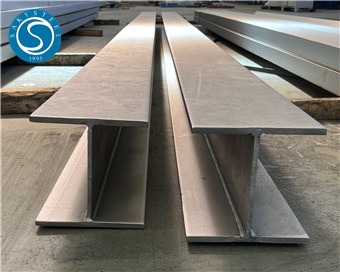

Isigaba Esiyisikwele(SHS):

I-Square Hollow Section (SHS) iphrofayili yensimbi enesiqephu esiyisikwele nendawo yangaphakathi engenalutho. Isetshenziswa kakhulu ekwakhiweni nasekukhiqizeni, i-SHS inikezela ngezinzuzo ezinjengokusebenza kahle kwamandla ukuya kwesisindo, ukuhlukahluka kwesakhiwo, kanye nokwenza lula. Ukuma kwayo kwejiyomethri ehlanzekile nosayizi abahlukahlukene kuyenza ifanele ukwakha amafreyimu, izakhiwo zokusekela, imishini, nezinye izinhlelo zokusebenza. I-SHS ivamise ukwenziwa ngezinto ezifana nensimbi noma i-aluminium, inamathela ezindinganisweni zemboni, futhi ingalashelwa ukumelana nokugqwala.

I-Square Hollow Section (SHS) ITHEBULA LAMA-DIMENSIONS/SIZES:

| Usayizi mm | kg/m | Usayizi mm | kg/m |

| 20 x 20 x 2.0 | 1.12 | 20 x 20 x 2.5 | 1.35 |

| 25 x 25 x 1.5 | 1.06 | 25 x 25 x 2.0 | 1.43 |

| 25 X 25 X 2.5 | 1.74 | 25 X 25 X 3.0 | 2.04 |

| 30 X 30 X 2.0 | 1.68 | 30 X 30 X 2.5 | 2.14 |

| 30 X 30 X 3.0 | 2.51 | 40 x 40 x 1.5 | 1.81 |

| 40 x 40 x 2.0 | 2.31 | 40 x 40 x 2.5 | 2.92 |

| 40 x 40 x 3.0 | 3.45 | 40 x 40 x 4.0 | 4.46 |

| 40 x 40 x 5.0 | 5.40 | 50 x 50 x 1.5 | 2.28 |

| 50 x 50 x 2.0 | 2.93 | 50 x 50 x 2.5 | 3.71 |

| 50 x 50 x 3.0 | 4.39 | 50 x 50 x 4.0 | 5.72 |

| 50 x 50 x 5.0 | 6.97 | 60 x 60 x 3.0 | 5.34 |

| 60 x 60 x 4.0 | 6.97 | 60 x 60 x 5.0 | 8.54 |

| 60 x 60 x 6.0 | 9.45 | 70 x 70 x 3.0 | 6.28 |

| 70 x 70 x 3.6 | 7.46 | 70 x 70 x 5.0 | 10.11 |

| 70 x 70 x 6.3 | 12.50 | 70 x 70 x 8 | 15.30 |

| 75 x 75 x 3.0 | 7.07 | 80 x 80 x 3.0 | 7.22 |

| 80 x 80 x 3.6 | 8.59 | 80 x 80 x 5.0 | 11.70 |

| 80 x 80 x 6.0 | 13.90 | 90 x 90 x 3.0 | 8.01 |

| 90 x 90 x 3.6 | 9.72 | 90 x 90 x 5.0 | 13.30 |

| 90 x 90 x 6.0 | 15.76 | 90 x 90 x 8.0 | 20.40 |

| 100 x 100 x 3.0 | 8.96 | 100 x 100 x 4.0 | 12.00 |

| 100 x 100 x 5.0 | 14.80 | 100 x 100 x 5.0 | 14.80 |

| 100 x 100 x 6.0 | 16.19 | 100 x 100 x 8.0 | 22.90 |

| 100 x 100 x 10 | 27.90 | 120 x 120 x 5 | 18.00 |

| 120 x 120 x 6.0 | 21.30 | 120 X 120 X 6.3 | 22.30 |

| 120 x 120 x 8.0 | 27.90 | 120 x 120 x 10 | 34.20 |

| 120 X 120 X 12 | 35.8 | 120 X 120 X 12.5 | 41.60 |

| 140 X 140 X 5.0 | 21.10 | 140 X 140 X 6.3 | 26.30 |

| 140 X 140 X 8 | 32.90 | 140 X 140 X 10 | 40.40 |

| 140 X 140 X 12.5 | 49.50 | 150 X 150 X 5.0 | 22.70 |

| 150 X 150 X 6.3 | 28.30 | 150 X 150 X 8.0 | 35.40 |

| 150 X 150 X 10 | 43.60 | 150 X 150 X 12.5 | 53.40 |

| 150 X 150 X 16 | 66.40 | 150 X 150 X 16 | 66.40 |

| 180 X 180 X 5 | 27.40 | 180 X 180 X 6.3 | 34.20 |

| 180 X 180 X 8 | 43.00 | 180 X 180 X 10 | 53.00 |

| 180 X 180 X 12.5 | 65.20 | 180 X 180 X 16 | 81.40 |

| 200 X 200 X 5 | 30.50 | 200 X 200 X 6 | 35.8 |

| 200 x 200 x 6.3 | 38.2 | 200 x 200 x 8 | 48.00 |

| 200 x 200 x 10 | 59.30 | 200 x 200 x 12.5 | 73.00 |

| 200 x 200 x 16 | 91.50 | 250 x 250 x 6.3 | 48.10 |

| 250 x 250 x 8 | 60.50 | 250 x 250 x 10 | 75.00 |

| 250 x 250 x 12.5 | 92.60 | 250 x 250 x 16 | 117.00 |

| 300 x 300 x 6.3 | 57.90 | 300 x 300 x 8 | 73.10 |

| 300 x 300 x 10 | 57.90 | 300 x 300 x 8 | 90.70 |

| 300 x 300 x 12.5 | 112.00 | 300 x 300 x 16 | 142.00 |

| 350 x 350 x 8 | 85.70 | 350 x 350 x 10 | 106.00 |

| 350 x 350 x 12.5 | 132.00 | 350 x 350 x 16 | 167.00 |

| 400 x 400 x 10 | 122.00 | 400 x 400 x 12 | 141.00 |

| 400 x 400 x 12.5mm | 152.00 | 400 x 400 x 16 | 192 |

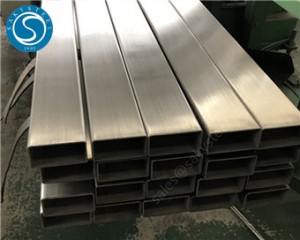

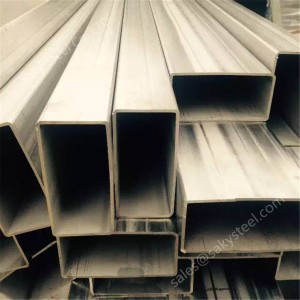

Isigaba Esingenalutho Esiwunxande(RHS):

I-Rectangular Hollow Section (RHS) iphrofayili yensimbi ebonakala ngesiphambano esingunxande nengaphakathi elingenalutho. I-RHS ivamise ukuqashwa ekwakhiweni nasekukhiqizeni ngenxa yokusebenza kahle kwesakhiwo nokuvumelana nezimo. Le phrofayili ihlinzeka ngamandla ngenkathi yehlisa isisindo, iyenze ifanelekele izinhlelo zokusebenza ezahlukahlukene njengamafreyimu wokwakha, izinhlaka zokusekela, nezingxenye zemishini. Ngokufanayo ne-Square Hollow Sections (SHS), i-RHS ivamise ukwenziwa ngezinto ezifana nensimbi noma i-aluminium futhi ilandela izindinganiso zomkhakha zobukhulu nokucaciswa. Umumo wayo ongunxande nosayizi abahlukahlukene kunikeza ukuguquguquka ekuhlangabezaneni nezidingo ezithile zobunjiniyela.

Isigaba Esingenalutho Esiwunxande (RHS) ITHEBULA LAMA-DIMENSIONS/SIZES:

| Usayizi mm | kg/m | Usayizi mm | kg/m |

| 40 x 20 x 2.0 | 1.68 | 40 x 20 x 2.5 | 2.03 |

| 40 x 20 x 3.0 | 2.36 | 40 x 25 x 1.5 | 1.44 |

| 40 x 25 x 2.0 | 1.89 | 40 x 25 x 2.5 | 2.23 |

| 50 x 25 x 2.0 | 2.21 | 50 x 25 x 2.5 | 2.72 |

| 50 x 25 x 3.0 | 3.22 | 50 x 30 x 2.5 | 2.92 |

| 50 x 30 x 3.0 | 3.45 | 50 x 30 x 4.0 | 4.46 |

| 50 x 40 x 3.0 | 3.77 | 60 x 40 x 2.0 | 2.93 |

| 60 x 40 x 2.5 | 3.71 | 60 x 40 x 3.0 | 4.39 |

| 60 x 40 x 4.0 | 5.72 | 70 x 50 x 2 | 3.56 |

| 70 x 50 x 2.5 | 4.39 | 70 x 50 x 3.0 | 5.19 |

| 70 x 50 x 4.0 | 6.71 | 80 x 40 x 2.5 | 4.26 |

| 80 x 40 x 3.0 | 5.34 | 80 x 40 x 4.0 | 6.97 |

| 80 x 40 x 5.0 | 8.54 | 80 x 50 x 3.0 | 5.66 |

| 80 x 50 x 4.0 | 7.34 | 90 x 50 x 3.0 | 6.28 |

| 90 x 50 x 3.6 | 7.46 | 90 x 50 x 5.0 | 10.11 |

| 100 x 50 x 2.5 | 5.63 | 100 x 50 x 3.0 | 6.75 |

| 100 x 50 x 4.0 | 8.86 | 100 x 50 x 5.0 | 10.90 |

| 100 x 60 x 3.0 | 7.22 | 100 x 60 x 3.6 | 8.59 |

| 100 x 60 x 5.0 | 11.70 | 120 x 80 x 2.5 | 7.65 |

| 120 x 80 x 3.0 | 9.03 | 120 x 80 x 4.0 | 12.00 |

| 120 x 80 x 5.0 | 14.80 | 120 x 80 x 6.0 | 17.60 |

| 120 x 80 x 8.0 | 22.9 | 150 x 100 x 5.0 | 18.70 |

| 150 x 100 x 6.0 | 22.30 | 150 x 100 x 8.0 | 29.10 |

| 150 x 100 x 10.0 | 35.70 | 160 x 80 x 5.0 | 18.00 |

| 160 x 80 x 6.0 | 21.30 | 160 x 80 x 5.0 | 27.90 |

| 200 x 100 x 5.0 | 22.70 | 200 x 100 x 6.0 | 27.00 |

| 200 x 100 x 8.0 | 35.4 | 200 x 100 x 10.0 | 43.60 |

| 250 x 150 x 5.0 | 30.5 | 250 x 150 x 6.0 | 38.2 |

| 250 x 150 x 8.0 | 48.0 | 250 x 150 x 10 | 59.3 |

| 300 x 200 x 6.0 | 48.10 | 300 x 200 x 8.0 | 60.50 |

| 300 x 200 x 10.0 | 75.00 | 400 x 200 x 8.0 | 73.10 |

| 400 x 200 x 10.0 | 90.70 | 400 x 200 x 16 | 142.00 |

I-Circular Hollow Sections(CHS):

I-Circular Hollow Section (CHS) iphrofayili yensimbi ehlukaniswa ngendawo ephambanayo eyindilinga kanye nengaphakathi elingenalutho. I-CHS isetshenziswa kabanzi ezinhlelweni zokwakha nezobunjiniyela, inikela ngezinzuzo ezinjengamandla esakhiwo, ukuqina kwe-torsional, kanye nokwenza lula. Le phrofayela ivame ukusetshenziswa ezimeni lapho umumo oyindilinga unenzuzo, njengamakholomu, izigxobo, noma izici zesakhiwo ezidinga ukusatshalaliswa komthwalo olinganayo.

I-RCircular Hollow Section (CHS) ITHEBULA LAMA-DIMENSIONS/SIZES:

| Igama elithi Bore mm | I-diameter yangaphandle mm | Ubukhulu mm | Isisindo kg/m |

| 15 | 21.3 | 2.00 | 0.95 |

| 2.60 | 1.21 | ||

| 3.20 | 1.44 | ||

| 20 | 26.9 | 2.30 | 1.38 |

| 2.60 | 1.56 | ||

| 3.20 | 1.87 | ||

| 25 | 33.7 | 2.60 | 1.98 |

| 3.20 | 0.24 | ||

| 4.00 | 2.93 | ||

| 32 | 42.4 | 2.60 | 2.54 |

| 3.20 | 3.01 | ||

| 4.00 | 3.79 | ||

| 40 | 48.3 | 2.90 | 3.23 |

| 3.20 | 3.56 | ||

| 4.00 | 4.37 | ||

| 50 | 60.3 | 2.90 | 4.08 |

| 3.60 | 5.03 | ||

| 5.00 | 6.19 | ||

| 65 | 76.1 | 3.20 | 5.71 |

| 3.60 | 6.42 | ||

| 4.50 | 7.93 | ||

| 80 | 88.9 | 3.20 | 6.72 |

| 4.00 | 8.36 | ||

| 4.80 | 9.90 | ||

| 100 | 114.3 | 3.60 | 9.75 |

| 4.50 | 12.20 | ||

| 5.40 | 14.50 | ||

| 125 | 139.7 | 4.50 | 15.00 |

| 4.80 | 15.90 | ||

| 5.40 | 17.90 | ||

| 150 | 165.1 | 4.50 | 17.80 |

| 4.80 | 18.90 | ||

| 5.40 | 21.30 | ||

| 150 | 168.3 | 5.00 | 20.1 |

| 6.3 | 25.2 | ||

| 8.00 | 31.6 | ||

| 10.00 | 39 | ||

| 12.5 | 48 | ||

| 200 | 219.1 | 4.80 | 25.38 |

| 6.00 | 31.51 | ||

| 8.00 | 41.67 | ||

| 10.00 | 51.59 | ||

| 250 | 273 | 6.00 | 39.51 |

| 8.00 | 52.30 | ||

| 10.00 | 64.59 | ||

| 300 | 323.9 | 6.30 | 49.36 |

| 8.00 | 62.35 | ||

| 10.00 | 77.44 |

Izici Nezinzuzo:

•Ukuklanywa kwezigaba ezingenalutho kuvumela ukugcina amandla esakhiwo ngenkathi kunciphisa isisindo.Lokhu kuklama kwenza izingxenye ezingenalutho zinikeze amandla aphezulu esakhiwo lapho zithwala imithwalo, ezifanele amaphrojekthi lapho ukucatshangelwa kwesisindo kubalulekile.

•Izingxenye ezingenalutho, ngokwakha ama-void phakathi kwesigaba esiphambanayo, zingasebenzisa izinto ngokuphumelelayo futhi zinciphise isisindo esingadingekile.Lokhu kuklanywa kwesakhiwo kusiza ukwehlisa izindleko zempahla ngenkathi kugcinwa amandla anele esakhiwo.

•Ngenxa yomumo wazo ovalekile, izingxenye ezingenalutho zibonisa ukuqina okuhle kakhulu kokugoba nokugoba.Le ndawo iqinisekisa ukusebenza okuzinzile lapho ibhekene nemithwalo esontekile noma egobayo.

•Izingxenye ezingenalutho zingenziwa ngezinqubo ezifana nokusika nokushisela, futhi kulula ukuzixhuma.Le nqubo elula yokukhiqiza nokuxhuma isiza ukwenza lula ukwakhiwa nokukhiqiza, ukuthuthukisa ukusebenza kahle.

•Izingxenye ezingenalutho azihlanganisi nje kuphela izimo eziyisikwele, eziwunxande, neziyindilinga kodwa futhi nezimo ezihlukahlukene zangokwezifiso ezisekelwe ezidingweni ezithile.Lokhu kuguquguquka kwenza izingxenye ezingenalutho zifanelekele uhla olubanzi lwezinhlelo zokusebenza zobunjiniyela nezokukhiqiza.

•Izingxenye ezingenalutho ngokuvamile zenziwe ngezinsimbi ezifana nensimbi, i-aluminium, nama-alloys ahlukahlukene.Lokhu kuhlukahluka kuvumela izingxenye ezingenalutho ukuthi zihlangabezane nezici ezibonakalayo ezidingekayo kumaphrojekthi wobunjiniyela ahlukene.

Ukwakheka Kwekhemikhali Kwesigaba esingenalutho esibandayo esakhiwe:

| Ibanga | C | Mn | P | S | Si | Cr | Ni | Mo |

| 301 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 16-18.0 | 6.0-8.0 | - |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17-19 | 8.0-10.0 | - |

| 304 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-10.5 | - |

| 304L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 18-20.0 | 9-13.5 | - |

| 316 | 0.045 | 2.0 | 0.045 | 0.030 | 1.0 | 10-18.0 | 10-14.0 | 2.0-3.0 |

| 316L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 16-18.0 | 12-15.0 | 2.0-3.0 |

| 430 | 0.12 | 1.0 | 0.040 | 0.030 | 0.75 | 16-18.0 | 0.60 | - |

Izakhiwo zikaMechanical :

| Ibanga | I-Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] |

| 304 | 75[515] | 30[205] |

| 304L | 70[485] | 25[170] |

| 316 | 75[515] | 30[205] |

| 316L | 70[485] | 25[170] |

Umhlahlandlela we-FAQ wesigaba esingenalutho :

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

yini isigaba esingenalutho?

Ingxenye engenalutho isho iphrofayili yensimbi enendawo yangaphakathi engenalutho, eza ngomumo njengesikwele, unxande, oyindilinga, noma imiklamo yangokwezifiso. Ngokuvamile ezenziwe ngensimbi, i-aluminium, noma ama-alloys, izingxenye ezingenalutho zisetshenziswa kakhulu ekwakheni nasekukhiqizeni. Zinikeza amandla anesisindo esincane, ukusatshalaliswa kwezinto ezisebenzayo, kanye nokuguquguquka kwezinhlelo zokusebenza ezifana nozimele bokwakha, izingxenye zemishini, nokuningi. Izingxenye ezingenalutho ziyaguquguquka, zenziwe kalula, futhi zivame ukwenziwa zifane ngokusekelwe kubukhulu nokucaciswa, okuzenza zibaluleke kumaphrojekthi ahlukahlukene wobunjiniyela nesakhiwo.

Ayini amashubhu angenalutho anesigaba esiphambano esiyindilinga?

Amashubhu angenalutho anesigaba esiphambanayo esiyindilinga, ezivamise ukwaziwa ngokuthi yi-circular hollow section (CHS), ayizakhiwo eziyisilinda ezinendawo yangaphakathi engenalutho. Ngokuvamile enziwa ngezinto ezifana nensimbi noma i-aluminium, lawa mashubhu athola ukusetshenziswa kabanzi ekwakheni nasekukhiqizeni. Umumo wabo oyindilinga uhlinzeka ngokusatshalaliswa kokucindezeleka okufanayo, okubenza bafanelekele izinhlelo zokusebenza ezifana namakholomu, izigxobo, nezisekelo zesakhiwo. Amashubhu ayindilinga anikeza ukuqina okuhle kokugoba nokugoba, enziwa kalula ngokusika nokushisela, futhi ngokuvamile anamathela kubukhulu obujwayelekile bokuvumelana nokuhambisana. Ngokuguquguquka nokuguquguquka, lawa mashubhu adlala indima ebalulekile ezimbonini ezahlukahlukene, kubandakanya nezokwakha nemishini.

Uyini umehluko phakathi kwesigaba esingenalutho kanye ne-I beam?

Izingxenye ezingenalutho amaphrofayili ensimbi anengaphakathi elingenalutho, atholakala ngamajamo afana nesikwele, unxande, noma isiyingi, avame ukusetshenziswa ekwakheni nasekukhiqizeni. Athola amandla emaphethelweni angaphandle esigaba.I-imishayo, ngakolunye uhlangothi, banesiphambano esimise okwe-I esine-flange eqinile kanye newebhu. Isetshenziswa kabanzi ekwakhiweni, imishayo ye-I isakaza isisindo ngobude besakhiwo, inikeze amandla kulo lonke. Ukukhetha phakathi kwabo kuncike ezidingweni ezithile zesakhiwo kanye nokucatshangelwa kokuklama.

Amakhasimende ethu

Impendulo Evela Kubathengi Bethu

Izingxenye ezingenalutho ngokuvamile zenziwe ngezinsimbi ezifana nensimbi, i-aluminium, nama-alloys ahlukahlukene.Lokhu kuhlukahluka kuvumela izigaba ezingenalutho ukuhlangabezana nezici ezibonakalayo ezidingekayo kumaphrojekthi wobunjiniyela ahlukene.Izimo zejometri zezingxenye ezingenalutho zivame ukuba nokukhanga kobuhle kunezigaba eziqinile, okuzenza zifanelekele amaphrojekthi lapho umklamo nobuhle bucatshangelwa.Ngenxa yokusetshenziswa kwazo kahle kwezinsizakusebenza, izigaba ezingenalutho zokuzijwayeza zemvelo zingakwazi ukunciphisa imfucumfucu ye-alig enobungane.

Ukupakisha:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,