Iziteshi Zensimbi Engagqwali H

Incazelo emfushane:

“Iziteshi zika-H” zibhekisela ezingxenyeni zesakhiwo ezimise njengohlamvu “H” ezivame ukusetshenziswa ekwakheni nasekusetshenzisweni kwesakhiwo okuhlukahlukene.

Iziteshi Zensimbi Engagqwali H:

Iziteshi zensimbi engagqwali H ziyizingxenye zesakhiwo ezibonakala ngesiphambano esimise okuka-H.Lezi ziteshi zakhiwe ngensimbi engagqwali, ingxubevange emelana nokugqwala eyaziwa ngokuhlala isikhathi eside, ukuhlanzeka, kanye nokukhanga kobuhle.Iziteshi zensimbi engagqwali H zithola izinhlelo zokusebenza ezimbonini ezihlukahlukene, okuhlanganisa ezokwakha, izakhiwo, nezokukhiqiza, lapho ukumelana nokugqwala kwazo namandla kuzenza zibe ukukhetha okuncanyelwayo kokusekelwa kwesakhiwo nokuklama.Lezi zingxenye zivame ukusetshenziswa ekwakhiweni kwezinhlaka, izisekelo, nokunye. izakhi zesakhiwo lapho kokubili amandla nokubukeka okupholishiwe kubalulekile.

Imininingwane Yeziteshi ze-H:

| Ibanga | 302,304,314,310,316,321 njll. |

| Okujwayelekile | ASTM A276, GB/T 11263-2010,ANSI/AISC N690-2010,EN 10056-1:2017 |

| Ubuso | hot rolled pickled , pholishiwe |

| Ubuchwepheshe | Okushisiwe Okushisiwe, Okushiselwe |

| Ubude | 1 kuya ku-6 Amamitha |

Izici Nezinzuzo:

•Idizayini emise okwesigaba esiphambanayo ethi "H" yensimbi ye-I-beam inikeza umthamo ovelele wokuthwala imithwalo yomibili imithwalo eqondile nevundlile.

•Umklamo wesakhiwo sensimbi ye-I-beam unikeza izinga eliphezulu lokuzinza, ukuvimbela ukuguquguquka noma ukugoba ngaphansi kokucindezeleka.

•Ngenxa yokuma kwayo okuyingqayizivele, insimbi ye-I-beam ingasetshenziswa kalula ezakhiweni ezihlukahlukene, okuhlanganisa imishayo, amakholomu, amabhuloho, nokuningi.

•Insimbi ye-I-beam yenza kahle kakhulu ekugobeni nasekucindezeleni, iqinisekisa ukuzinza ngaphansi kwezimo eziyinkimbinkimbi zokulayisha.

•Ngokuklama kwayo okuphumelelayo namandla aphakeme, insimbi ye-I-beam ngokuvamile inikeza ukusebenza kahle kwezindleko.

•Insimbi ye-I-beam ithola ukusetshenziswa okubanzi ekwakhiweni, amabhuloho, okokusebenza kwezimboni, nakweminye imikhakha eyahlukene, ikhombisa ukuguquguquka kwayo kuwo wonke amaphrojekthi wobunjiniyela nesakhiwo.

•Idizayini yensimbi ye-I-beam iyivumela ukuthi ivumelane kangcono nezidingo zokwakha okusimeme nokuklama, inikeze isisombululo esisebenzayo sesakhiwo semikhuba yokwakha enobungani bemvelo neluhlaza.

Ukubunjwa Kwamakhemikhali H Iziteshi:

| Ibanga | C | Mn | P | S | Si | Cr | Ni | Mo | I-nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Izakhiwo zemishini Yeziteshi ze-H:

| Ibanga | I-Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu.Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu.Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Yiziphi izindlela zokushisela?

Izindlela zokushisela zihlanganisa i-arc welding, i-gas shielded welding (i-MIG/MAG welding), i-welding resistance, i-laser welding, i-plasma arc welding, i-friction stir welding, i-pressure welding, i-electron beam welding, njll. Indlela ngayinye inezinhlelo zokusebenza eziyingqayizivele nezici, ezifanele ezihlukahlukene. izinhlobo zezinto zokusebenza kanye nezidingo zokukhiqiza.I-arc isetshenziselwa ukukhiqiza amazinga okushisa aphezulu, ukuncibilikisa insimbi ebusweni bomsebenzi ukuze yakhe uxhumano.Izindlela zokushisela i-arc ezivamile zihlanganisa i-arc welding manual, i-argon arc welding, i-arc welding engaphansi kwamanzi, njll.Ukushisa okukhiqizwa ukumelana kusetshenziselwa ukuncibilikisa insimbi ebusweni bomsebenzi ukuze kwakhiwe uxhumano.I-Resistance welding ihlanganisa i-spot welding, i-seam welding kanye ne-bolt welding.

Yiziphi izinzuzo zokushisela i-arc engaphansi kwamanzi?

I-arc welding engaphansi kwamanzi ilungele ukuzishintshanisa nendawo enevolumu ephezulu.Ingakwazi ukuqedela inani elikhulu lomsebenzi wokushisela ngesikhathi esifushane futhi ithuthukise ukusebenza kahle kokukhiqiza.I-arc welding engaphansi kwamanzi ilungele ukuzishintshanisa nendawo enevolumu ephezulu.Ingakwazi ukuqedela inani elikhulu lomsebenzi wokushisela ngesikhathi esifushane futhi ithuthukise ukusebenza kahle kokukhiqiza.I-arc welding engaphansi kwamanzi ijwayele ukusetshenziselwa ukushisela amashidi ensimbi aminyene ngoba ukungena kwawo okuphezulu kwamanje nokuphezulu kuwenza asebenze kangcono kulezi zinhlelo zokusebenza.Njengoba i-weld imbozwe yi-flux, umoya-mpilo ungavinjelwa ngokuphumelelayo ukuthi ungangeni endaweni yokushisela, ngaleyo ndlela unciphise amathuba okuba ne-oxidation kanye ne-spatter.Uma kuqhathaniswa nezinye izindlela zokushisela okwenziwa ngesandla, ukushisela kwe-arc okungaphansi kwamanzi kungase kuzenzekele kalula, kunciphise izidingo eziphakeme amakhono abasebenzi.Ekushiseleni kwe-arc engaphansi kwamanzi, izintambo eziningi zokushisela nama-arcs zingasetshenziswa ngesikhathi esisodwa ukuze kuzuzwe ukushisela kweziteshi eziningi (izingqimba eziningi) nokuthuthukisa ukusebenza kahle.

Isingeniso somumo we-H beam ?

Umumo we-cross-sectional we-I-beam steel, ovame ukwaziwa ngokuthi "工字钢" (gōngzìgāng) ngesi-Chinese, ufana nohlamvu oluthi "H" uma luvulwa.Ngokucacile, isigaba esiphambene ngokuvamile siqukethe amabha amabili avundlile (ama-flange) phezulu naphansi kanye nebha emaphakathi eqondile (iwebhu).Lo mumo othi "H" unikeza amandla aphakeme nokuzinza kunsimbi ye-I-beam, okuyenza ibe into evamile yesakhiwo ekwakhiweni nasebunjiniyela.Umumo oklanyelwe we-I-beam steel uyivumela ukuthi ifanelekele izinhlelo zokusebenza ezihlukahlukene zokuthwala nokusekela, ezifana njengemishayo, amakholomu, nezakhiwo zebhuloho.Lokhu kumiswa kwesakhiwo kuvumela insimbi ye-I-beam ukuthi isabalalise ngempumelelo imithwalo uma ingaphansi kwamandla, ihlinzeka ngokusekelwa okuqinile.Ngenxa yokuma kwayo okuyingqayizivele nezici zesakhiwo, insimbi ye-I-beam ithola ukusetshenziswa kabanzi emkhakheni wokwakha nobunjiniyela.

Ungawuveza kanjani usayizi nenkulumo ye-I-beam?

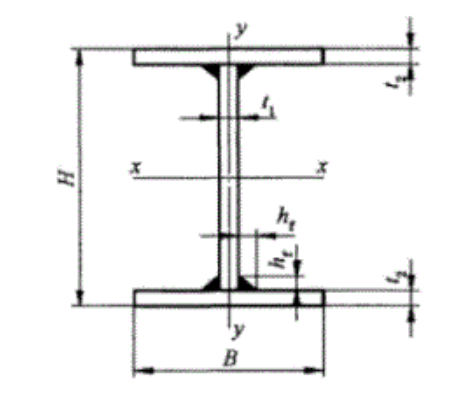

H——Phezulu

B——Ububanzi

t1——Ukujiya kwewebhu

t2——Ubukhulu bepuleti le-Flange

h£——Usayizi wokushisela (uma usebenzisa inhlanganisela yezinqe nefillet, kufanele kube usayizi womlenze wokushisela oqinisiwe ongu-hk)

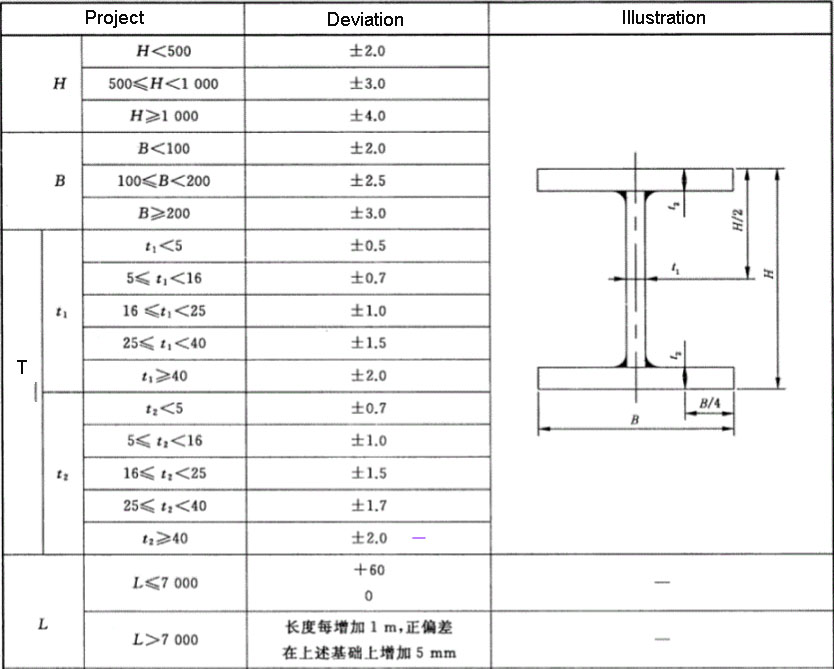

Ubukhulu, umumo kanye nokuchezuka okuvumelekile kwensimbi eshiselwe okumise okuka-H

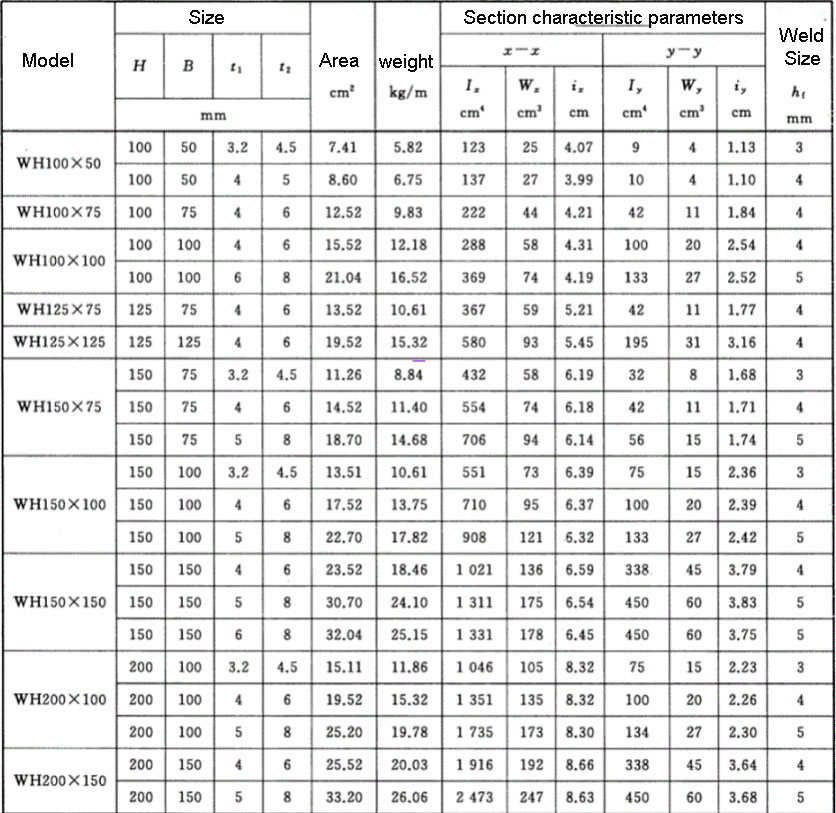

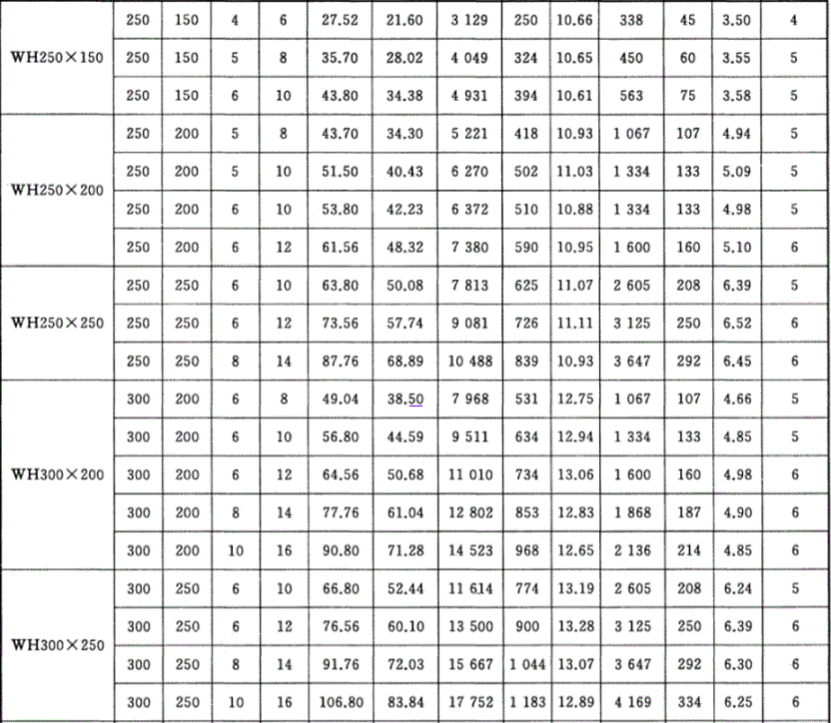

Ubukhulu besigaba esiphambanayo, indawo ephambanayo, isisindo setiyori kanye nemingcele yesici eyisiphambano sensimbi eshiselwe okumise okuka-H

Amakhasimende ethu

Impendulo Evela Kubathengi Bethu

Iziteshi Zensimbi Engagqwali H ziyizingxenye zesakhiwo eziguquguqukayo ezakhiwe ngensimbi engagqwali yekhwalithi ephezulu.Lezi ziteshi zifaka umumo othi "H" ohlukile, onikeza amandla athuthukisiwe nokuzinza ezinhlelweni ezihlukahlukene zokwakha nezakhiwo.Isiphetho esihle nesiphucuziwe sensimbi engagqwali sinezela ukuthinta okuyinkimbinkimbi, okwenza lezi ziteshi ze-H zifanelekele kokubili izakhi zedizayini ezisebenzayo nezikhangayo. Umklamo omise okwe-H ukhulisa umthamo wokuthwala umthwalo, okwenza lezi ziteshi zibe zilungele ukusekela imithwalo esindayo ezindaweni zokwakha kanye nezimboni.Iziteshi ze-Stainless Steel H zithola izinhlelo zokusebenza ezimbonini ezihlukahlukene, ezihlanganisa ukwakhiwa, izakhiwo, nokukhiqiza, lapho ukusekelwa kwesakhiwo esiqinile kubalulekile.

Ukupakisha:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni.Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,