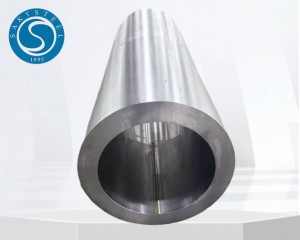

DIN 1.2311 P20 Mold Steel

ʻO ka wehewehe pōkole:

ʻO DIN 1.2311 ″ kahi ʻano maʻamau o ke kila kila, i kapa pinepine ʻia ʻo P20 kila. ʻO P20 kahi kila kila haʻahaʻa i ʻike ʻia no kona machinability maikaʻi a me ke kūpaʻa ʻana, hoʻohana mau ʻia i ka hana ʻana i nā mold plastic a me nā mold diecasting.

DIN 1.2311 P20 hao hao:

ʻO DIN 1.2311 P20 Mold Steel he mea hoʻohana maʻamau i hoʻohana ʻia, hoʻohana nui ʻia i ka hana ʻana i nā mold plastic a me nā mold die-casting. nā koi. DIN 1.2311 P20 Mold Steel ka mea maʻamau i hoʻohana ʻia i nā ʻano like ʻole e like me ka injection molds, extrusion molds, die-casting molds, a me ka mold base.

Nā ʻōlelo kikoʻī o 1.2311 NĀ MEA HANA:

| Papa | 1.2311,P20 |

| Kūlana | ASTM A681 |

| Ili | ʻeleʻele; Peeled; Hoʻomaʻamaʻa ʻia; Mīkini; wili ʻia; Huli; Milled |

| Mahele Raw | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

1.2311 Kaulike kila kila:

| ʻāina | USA | Alemania | GB/T |

| Kūlana | ASTM A681 | DIN EN ISO 4957 | GB/T 1299 |

| Papa helu | P20 | 1.2311 | 3Cr2Mo |

P20 NĀ KĀMĀNĀ KĀMI

| Kūlana | Papa | C | Si | Mn | P | S | Cr | Mo |

| ASTM A681 | P20 | 0.28~0.40 | 0.2~0.8 | 0.60~1.0 | ≤0.030 | ≤0.030 | 1.4~2.0 | 0.3~0.55 |

| GB/T 9943 | 3Cr2Mo | 0.28~0.40 | 0.2~0.8 | 0.60~1.0 | ≤0.030 | ≤0.030 | 1.4~2.0 | 0.3~0.55 |

| DIN ISO4957 | 1.2311 | 0.35~0.45 | 0.2~0.4 | 1.3~1.6 | ≤0.030 | ≤0.030 | 1.8~2.1 | 0.15~0.25 |

1.2311 NA MEA HANA NUI.

| Waiwai | Metric |

| Paʻakiki, Brinell (Maʻamau) | 300 |

| Paʻakiki, Rockwell C (Maʻamau) | 30 |

| Ikaika U'i, Loa | 965-1030 MPa |

| Ikaika U'i, Hua | 827-862 MPa |

| ʻO ka hoʻolōʻihi ʻia i ka haki ʻana (Ma ka 50 Mm (2″) | 20.00% |

| Ka ikaika hoʻopili | 862 MPa |

| ʻO Charpy Impact (V-Notch) | 27.1-33.9 J |

| Ka Laki o Poisson | 0.27-0.30 |

| Elastic Modulus | 190-210 GPa |

No ke aha e koho ai iā mākou?

•Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

•Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka i ka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

•Hiki ke hōʻoia ʻia nā mea a mākou e hāʻawi ai, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope. (E hōʻike ʻia nā hōʻike ma ke koi)

•Ke hōʻoiaʻiʻo nei mākou e hāʻawi i kahi pane i loko o 24 mau hola (maʻamau i ka hola hoʻokahi)

•Hāʻawi i ka hōʻike SGS TUV.

•Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

•Hāʻawi i ka lawelawe hoʻokahi.

ʻO kā mākou lawelawe

1.Quenching a me ka tempering

2.Vacuum wela mālama

3.Mirror-polished ili

4.Precision-milled pau

4.CNC machining

5.Precision wili

6.ʻokiʻoki i nā'āpana liʻiliʻi

7. Loaʻa i ka pololei e like me ka mold

Hoʻopili:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,