15-5PH Paʻa Paʻa Paʻa

ʻO ka wehewehe pōkole:

ʻO 15-5 PH ke kila kila he martensitic precipitation-hardening stainless steel e hāʻawi ana i ka ikaika kiʻekiʻe, paʻakikī, a me ka pale ʻana i ka corrosion. Hoʻohana maʻamau ia i nā noi e koi ana i ka ikaika kiʻekiʻe a me ka paʻakikī i hui pū ʻia me ke kūpaʻa corrosion maikaʻi loa.

15-5PH pae hao hao:

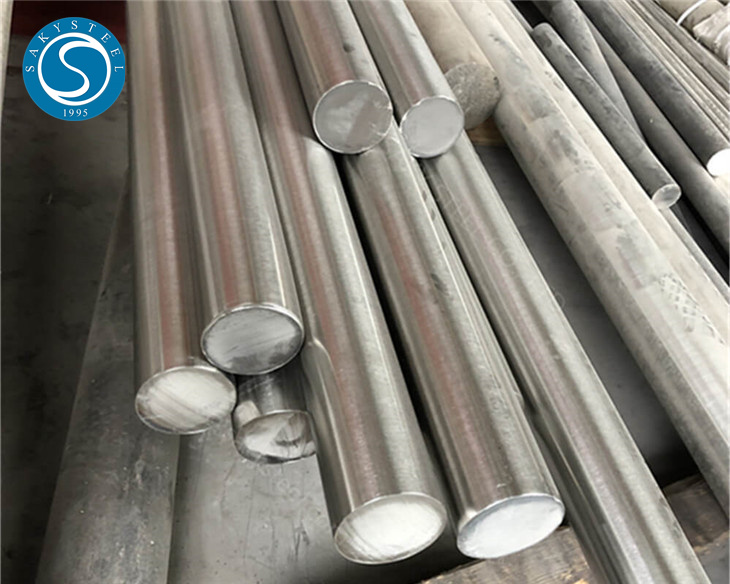

ʻO 15-5PH ka pahu kila kila he ʻano pahu kūikawā i hana ʻia mai ka 15-5 precipitation-hardening stainless steel. Hāʻawi ia i ka ikaika kiʻekiʻe a me ka paʻakikī, e kūpono ia no nā noi e koi ana i nā mea ikaika. ʻoi aku ka paʻakikī i ka mīkini ma hope o ka mālama ʻana i ka wela ma muli o ka hoʻonui ʻia ʻana o ka paʻakikī.

Nā kikoʻī o 15-5PH Bar:

| Papa | 15-5PH,1.4545,XM-12 |

| Kūlana | ASTM A564 |

| Ka lōʻihi | 1 a 6 mau mika, nā lōʻihi ʻoki maʻamau |

| Hoʻopau | Alohilohi, Polani & ʻEleʻele |

| Puka | Poe, huinaha, Hex (A/F), Rectangle, Uea (Coil Form), Wiremesh, Billet, Ingot, Forging Etc. |

| Ili | ʻeleʻele; Peeled; Hoʻomaʻamaʻa ʻia; Mīkini; wili ʻia; Huli; Milled |

| Kūlana | Huki Anuanu & Ho'oma'ama'a Huki Anuanu, 'Āina Waena 'ole & Polished |

| Mahele Raw | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

15-5 PH Poepoe Bar Equivalent Standard:

| KANAWAI | UNS | WERKSTOFF NR. |

| 15-5 PH | S15500 | 1.4545 |

ʻO ka ASTM A564 XM-12 Bar Chemical Composition:

| C | Si | Mn | P | S | Cr | Mo | Cu |

| 0.07 | 1.0 | 1.0 | 0.03 | 0.015 | 14.0-15.0 | 0.5 | 2.5-4.5 |

15-5 PH Nā Pa'a Po'ai Po'ai Nā Pono Mechanical:

| ʻO ka ikaika hoʻopale (ksi) min | Elongation (% i 50mm) min | ʻO ka ikaika 0.2% Hōʻoia (ksi) min | ʻoʻoleʻa |

| 190 | 10 | 170 | 388 |

No ke aha e koho ai iā mākou?

•Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

•Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka i ka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

•Hiki ke hōʻoia ʻia nā mea a mākou e hāʻawi ai, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope. (E hōʻike ʻia nā hōʻike ma ke koi)

•Ke hōʻoiaʻiʻo nei mākou e hāʻawi i kahi pane i loko o 24 mau hola (maʻamau i ka hola hoʻokahi)

•Hāʻawi i ka hōʻike SGS TUV.

•Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

•Hāʻawi i ka lawelawe hoʻokahi.

ʻO kā mākou lawelawe

1.Quenching a me ka tempering

2.Vacuum wela mālama

3.Mirror-polished ili

4.Precision-milled pau

4.CNC machining

5.Precision wili

6.ʻokiʻoki i nā'āpana liʻiliʻi

7. Loaʻa i ka pololei e like me ka mold

Hoʻopili:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,