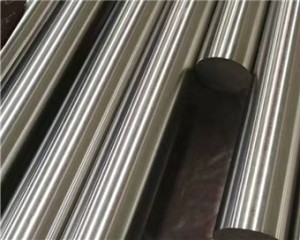

A182/A182M UNS S32615 Duplex Bar

ʻO ka wehewehe pōkole:

| Nā kikoʻī o S32615 RoundBar: |

| Nā kikoʻī | ASTM A182/ A182M |

| Papa | S32615 |

| Nui | 6 mm a 120 mm |

| Ka lōʻihi | 1 mika a 6 mika, ka lōʻihi oki maʻamau |

| mānoanoa | 100 mm a 600 mm |

| ʻenehana | Papa ʻōwili wela (HR), Pepa ʻōwili anu (CR) |

| Hoʻopau ʻili | ʻEleʻele, Hoʻomaʻamaʻa ʻulaʻula, Huli ʻo Rough, NO.4 Finish, Matt Finish, BA Finish |

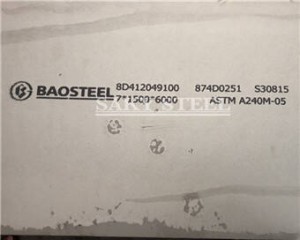

| Mahele Raw | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

| Puka | Nā Bara Poe, Nā ʻAi Kūlike, Nā Paʻa Paʻa, Nā ʻAi Uila, Nā ʻAha Hollow, Nā ʻAi Hexagonal, nā ʻAi Triangular, Hex, Rectangle, Flat, Ingot, etc. |

| Hoʻopili i nā mea hoʻohana wiliwili | Hoʻohana ʻia ka hoʻohana ʻana o S32760 duplex steelER2209 uwea wiliwili. |

| ʻO ke kila kila S32615 Poʻa Poʻe Kaulike Kaulike: |

| KANAWAI | WERKSTOFF NR. | UNS |

| S32615 | 1.4507 | S32615 |

| 1.4507 Bar Ka Hui Kimia a me Mechanical waiwai (saky kila): |

| Papa | C | Cr | Mn | Si | N | Mo | S | P | Ni |

| S32615 | 0.03 ka nui | 24.0-26.0 | 2.0 ka nui | 1.0max | 0.1-0.20 | 3.0-4.5 | 0.02 ka nui | 0.03 ka nui | 6.0-9.0 |

| Ikaika U'i | Ka ikaika o ka hua (0.2%offset) | Elongation (i loko o 2 in.) |

| 760Mpa | 550Mpa | 25 % |

| No ke aha e koho ai iā mākou: |

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi ai ua hiki ke hōʻoiaʻiʻoʻia, mai ka palapala hōʻoia hōʻike maka a hiki i ka'ōlelo hope loa. (E hōʻikeʻia nā hōʻike ma ke koi)

4. e hōʻoiaʻiʻo e hāʻawi i ka pane i loko o 24 hola (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

| ʻO SAKY STEEL'S Quality Assurance (me nā mea hoʻopau a me ka hoʻopau ʻole): |

1. Ho'āʻo ʻia ʻike

2. Mechanical nānā 'ana e like me tensile, Elongation a me ka ho'ēmi 'āpana.

3. Ka nānā 'ana i ka hopena

4. Ka nānā 'ana i ka ho'ā'o kemika

5. Hoao paakiki

6. Ho'āʻo pale lua

7. Hoao Penetrant

8. Intergranular Corrosion Ho'āʻo

9. Ho'āʻo Roughness

10. Ho'āʻo hoʻokolohua Metallography

| ʻO SAKY STEEL'S Packaging: |

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,

Nā noi:

1.ʻOihanaʻaila a me ke kinoea.

2. ʻOihana Petrochemical ( polymerization reactor cycle pumps and pipework)

3.Offshore platforms (nā mea hoʻololi wela, nā kaʻina hana a me nā ʻōnaehana wai lawelawe, nā ʻōnaehana pale ahi, a me nā ʻōnaehana wai a me ka ballast)

4. Nā ʻoihana hana kemika (nā mea hoʻololi wela a me nā moku)

5.Desalination mea kanu (kiʻekiʻe puʻe RO-mea kanu a me ke kai paipu)

6. Nā meaʻai (Recirculation tanks, sedimentation tanks, phosphate reactor recirculation pumps)

7. ʻOihana mana FGD pūnaewele

8. Utility a me nā ʻōnaehana scrubber ʻoihana (nā hale kiaʻi absorber, ducting, pipe)

9.Mining/ Extraction (wela slurry pipe hana, acid leach mining)

10. Sewage (nā paipu koʻikoʻi koʻikoʻi.)

11. Nā noi ʻenehana (nā moku kaomi)