ER2209 ER2553 ER2594 Uea Uea

ʻO ka wehewehe pōkole:

ER 2209ua hoʻolālā ʻia e wili i nā kila stainless duplex e like me 2205 (UNS Number N31803). ʻO ka ikaika tensile kiʻekiʻe a me ka hoʻomaikaʻi ʻana i ke kūpaʻa ʻana i ke koʻikoʻi i ka haki ʻana o ka corrosion a me ka pitting ke ʻano o nā welds o kēia uea. He haʻahaʻa kēia uea i ka ferrite i hoʻohālikelike ʻia me ka metala kumu i mea e loaʻa ai ka maikaʻi o ka weldability.

ER 2553hoʻohana mua ʻia e wili i nā kila kuhili ʻole duplex i loaʻa ma kahi o 25% chromium. Loaʻa iā ia kahi microstructure 'duplex' me kahi matrix austenite-ferrite. Hōʻike ʻia kēia alloy duplex e ka ikaika tensile kiʻekiʻe, ka pale ʻana i ke koʻikoʻi corrosion cracking a me ka hoʻomaikaʻi ʻana i ke kūʻē ʻana i ka pitting.

ER 2594he uwea wiliwili superduplex. ʻO ka Pitting Resistance Equivalent Number (PREN) ma kahi o 40, no laila e ʻae ai i ka weld metala e kapa ʻia he kila kila superduplex. Hāʻawi kēia uea welding i nā ʻano kemika like ʻole a me nā ʻano waiwai mechanical i nā alloys superduplex i hana ʻia e like me 2507 a me Zeron 100 a me nā mea hoʻolei hoʻoheheʻe superduplex (ASTM A890). Hoʻopili ʻia kēia uea kuʻi ʻana i ka 2-3 pakeneka ma Nickel e hāʻawi i ka ratio ferrite/austenite maikaʻi loa i ka weld i hoʻopau ʻia. Hoʻokumu kēia ʻano hana i ka ikaika tensile kiʻekiʻe a me ka hoʻoulu ʻana me ke kūpaʻa kiʻekiʻe i ka SCC a me ka pitting corrosion.

| Nā kikoʻī o ka Welding Wire Rod: |

Nā kikoʻī:AWS 5.9, ASME SFA 5.9

Papa:TIG/MIG ER304 ER308L ER308L ER309L,ER2209 ER2553 ER2594

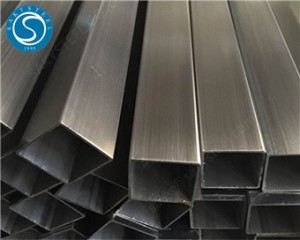

Anawaena uwea welding :

MIG – 0.8 a 1.6 mm,

TIG - 1 a 5.5 mm,

Uea kumu - 1.6 a 6.0

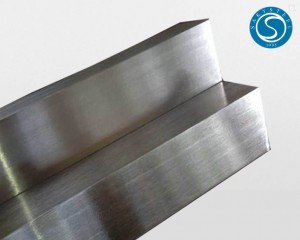

Ili:Alohilohi, Ao, Pulu, ʻEleʻele

| ER2209 ER2553 ER2594 Ke koʻokoʻo uwea kuʻi Hoʻohui Kemika a me nā waiwai Mechanical (saky steel): |

| Papa | C | Mn | Si | P | S | Cr | Ni |

| ER2209 | 0.03 ka nui | 0.5 – 2.0 | 0.9 ka nui | 0.03 ka nui | 0.03 ka nui | 21.5 – 23.5 | 7.5 – 9.5 |

| ER2553 | 0.04 ka nui | 1.5 | 1.0 | 0.04 ka nui | 0.03 ka nui | 24.0 – 27.0 | 4.5 – 6.5 |

| ER2594 | 0.03 ka nui | 2.5 | 1.0 | 0.03 ka nui | 0.02 ka nui | 24.0 -27.0 | 8.0 – 10.5 |

| No ke aha e koho ai iā mākou: |

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi nei ua hiki ke hōʻoia ʻia, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope loa. (E hōʻike ʻia nā hōʻike ma ke koi)

4. e hōʻoiaʻiʻo e hāʻawi i ka pane i loko o 24 hola (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

| ʻO SAKY STEEL'S Quality Assurance (me nā mea hoʻopau a me ka hoʻopau ʻole): |

1. Ho'āʻo ʻia ʻike

2. Mechanical nānā 'ana e like me tensile, Elongation a me ka ho'ēmi 'āpana.

3. Ka nānā 'ana i ka hopena

4. Ka nānā 'ana i ka ho'ā'o kemika

5. Hoao paakiki

6. Ho'āʻo pale lua

7. Hoao Penetrant

8. Intergranular Corrosion Ho'āʻo

9. Ho'āʻo Roughness

10. Ho'āʻo hoʻokolohua Metallography

| ʻO SAKY STEEL'S Packaging: |

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,

ʻŌlelo pūʻolo:

| ʻAno Uea | Nui Uea | Hoʻopili | Kaumaha Upena | |||||||||

| Uea MIG | φ0.8~1.6(mm) | D100mm D200mm D300mm D270mm | 1kg 5kg 12.5kg 15kg 20kg | |||||||||

| Uea TIG | φ1.6~5.5(mm) | 1 mika/Pahu | 5 kg 10 kg | |||||||||

| Uea kumu | φ1.6~5.5(mm) | Coil a Pahu paha | 30kg – 500kg | |||||||||