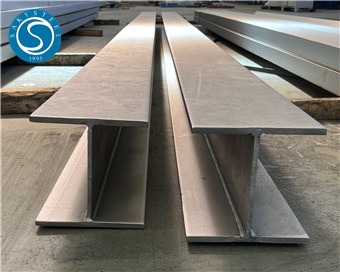

Insimbi engagqwali HI Beam

Incazelo emfushane:

I-“H Beam” ibhekisela ezingxenyeni zesakhiwo ezimise njengohlamvu “H” ezivame ukusetshenziswa ekwakheni nasekusetshenzisweni kwesakhiwo okuhlukahlukene.

Insimbi Engagqwali H Beam:

Insimbi engagqwali i-H Beam iyingxenye yesakhiwo ebonakala ngesiphambano esimise okuka-H. Lezi ziteshi zakhiwe ngensimbi engagqwali, ingxubevange emelana nokugqwala eyaziwa ngokuhlala isikhathi eside, ukuhlanzeka, kanye nokukhanga kobuhle. Iziteshi zensimbi engagqwali H zithola izinhlelo zokusebenza ezimbonini ezihlukahlukene, ezihlanganisa ezokwakha, izakhiwo, nezokukhiqiza, lapho ukumelana nokugqwala kwazo namandla kuzenza ukukhetha okuncanyelwayo kokusekelwa kwesakhiwo nokuklama.Lezi zingxenye zivame ukusetshenziswa ekwakhiweni kwezinhlaka, izisekelo, nezinye izakhi zesakhiwo lapho kokubili amandla nokubukeka okupholishiwe kubalulekile.

Imininingwane ye-I Beam:

| Ibanga | 302 304 304L 310 316 316L 321 2205 2507 njll. |

| Okujwayelekile | I-GB T33814-2017,GBT11263-2017 |

| Ubuso | Ukuqhunyiswa kwesihlabathi, ukupholishwa, ukuqhunyiswa kwesibhamu |

| Ubuchwepheshe | Okushisiwe Okushisiwe, Okushiselwe |

| Ubude | 1 kuya ku-12 Amamitha |

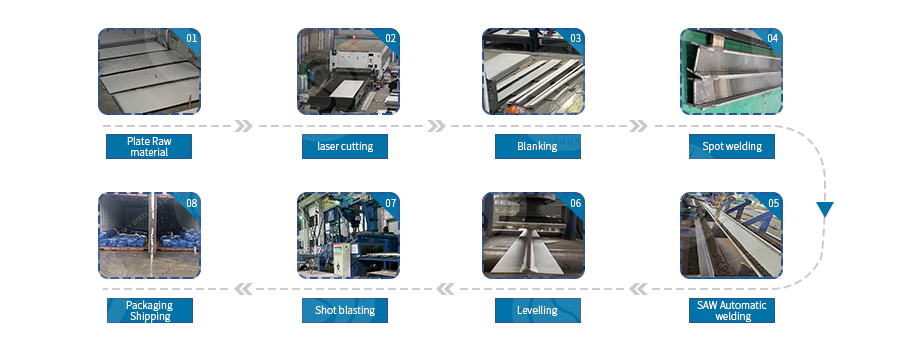

Ishadi lokugeleza kokukhiqiza kwe-I-beam:

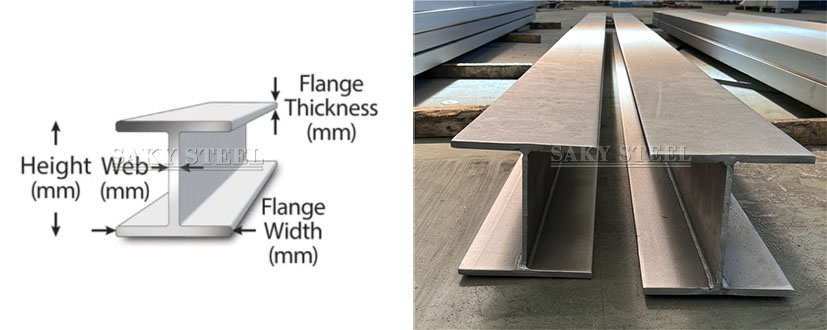

Iwebhu:

Iwebhu isebenza njengengqikithi emaphakathi ye-beam, ngokuvamile ehlelwa ngokususelwe ekugqimeni kwayo. Isebenza njengesixhumanisi sesakhiwo, idlala indima ebalulekile ekugcineni ubuqotho be-beam ngokuxhuma nokuhlanganisa ama-flange amabili, ukusabalalisa ngempumelelo nokulawula ingcindezi.

I-Flange:

Izingxenye eziphansi ezingaphezulu neziyisicaba zensimbi zithwala umthwalo oyinhloko. Ukuze siqinisekise ukusatshalaliswa kwengcindezi efanayo, sicaba ama-flange. Lezi zingxenye ezimbili zisebenza ngokufana, futhi kumongo we-I-imishayo, zifaka izandiso ezifana namaphiko.

I-H Beam Welded Line Ukukala ukujiya:

Inqubo ye-Stainless Steel I Beam Beveling:

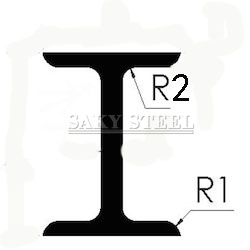

I-engeli engu-R ye-I-beam ipholishiwe ukwenza indawo ibushelelezi futhi ingabi nama-burr, okuyinto elungele ukuvikela ukuphepha kwezisebenzi. Singacubungula i-engeli engu-R ka-1.0, 2.0, 3.0. 304 316 316L 2205 Imishayo ye-Stainless Steel IH. Ama-engeli angu-R emigqa engu-8 wonke aphucuziwe.

I-Stainless Steel I Beam Wing/Flange straighting:

Izici Nezinzuzo:

•Idizayini emise okwesigaba esiphambanayo ethi "H" yensimbi ye-I-beam inikeza umthamo ovelele wokuthwala imithwalo yomibili imithwalo eqondile nevundlile.

•Umklamo wesakhiwo sensimbi ye-I-beam unikeza izinga eliphezulu lokuzinza, ukuvimbela ukuguquguquka noma ukugoba ngaphansi kokucindezeleka.

•Ngenxa yokuma kwayo okuyingqayizivele, insimbi ye-I-beam ingasetshenziswa kalula ezakhiweni ezihlukahlukene, okuhlanganisa imishayo, amakholomu, amabhuloho, nokuningi.

•Insimbi ye-I-beam yenza kahle kakhulu ekugobeni nasekucindezeleni, iqinisekisa ukuzinza ngaphansi kwezimo eziyinkimbinkimbi zokulayisha.

•Ngokuklama kwayo okuphumelelayo namandla aphakeme, insimbi ye-I-beam ngokuvamile inikeza ukusebenza kahle kwezindleko.

•Insimbi ye-I-beam ithola ukusetshenziswa okubanzi ekwakhiweni, amabhuloho, okokusebenza kwezimboni, nakweminye imikhakha eyahlukene, ikhombisa ukuguquguquka kwayo kuwo wonke amaphrojekthi wobunjiniyela nesakhiwo.

•Idizayini yensimbi ye-I-beam iyivumela ukuthi ivumelane kangcono nezidingo zokwakha nokuklama okusimeme, inikeze isisombululo esisebenzayo sesakhiwo sezinqubo zokwakha ezinobungani bemvelo kanye neziluhlaza.

Ukwakhiwa Kwekhemikhali H Beam:

| Ibanga | C | Mn | P | S | Si | Cr | Ni | Mo | I-nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Izindawo zokuhlala ezengeziwe e-I Beams:

| Ibanga | I-Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

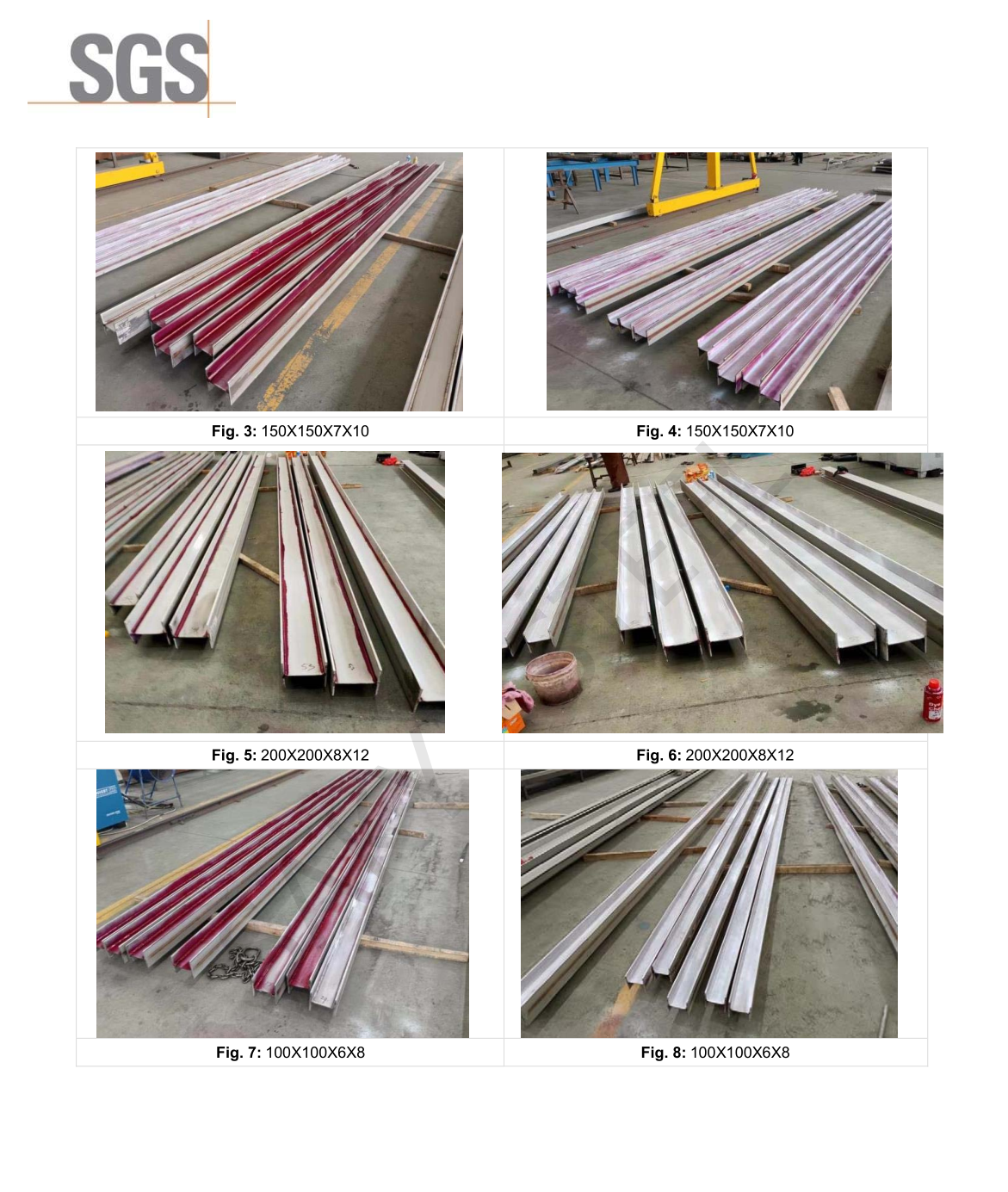

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

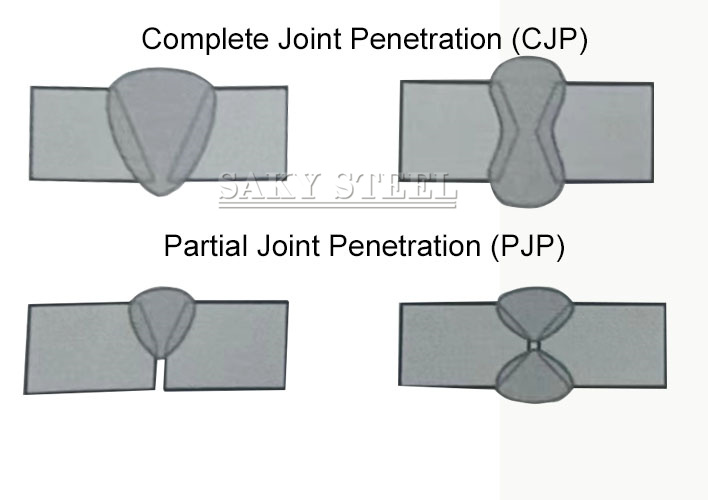

316L insimbi engagqwali eshiselwe ukuhlolwa kwe-H Beam Penetration (PT)

Isekelwe ku-JBT 6062-2007 Ukuhlola okungabhubhi - ukuhlolwa kokungena kwama-welds we-304L 316L yensimbi engagqwali eshiselwe i-H Beam.

Yiziphi izindlela zokushisela?

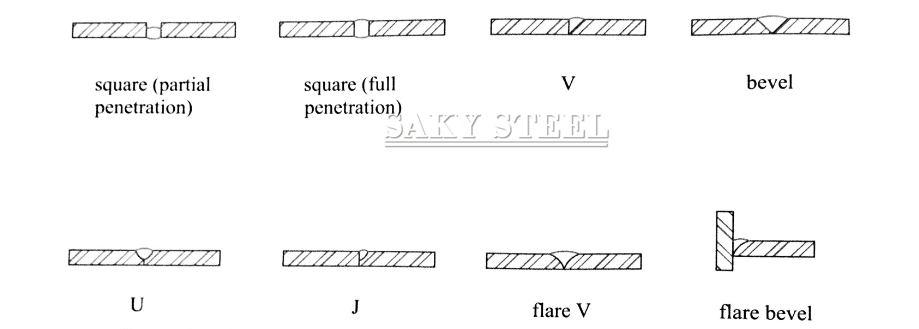

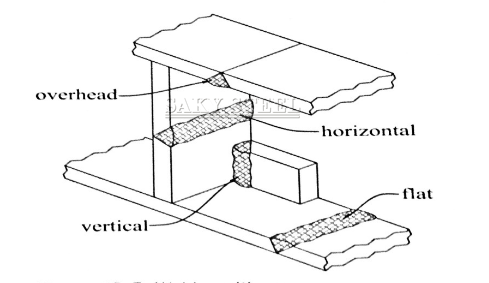

Izindlela zokushisela zihlanganisa i-arc welding, i-gas shielded welding (MIG/MAG welding), i-resistance welding, i-laser welding, i-plasma arc welding, i-friction stir welding, i-pressure welding, i-electron beam welding, njll. Izindlela zokushisela i-arc ezivamile zihlanganisa i-arc welding manual, i-argon arc welding, i-arc welding engaphansi kwamanzi, njll.Ukushisa okukhiqizwa ukumelana kusetshenziselwa ukuncibilikisa insimbi ebusweni bomsebenzi ukuze kwakhiwe uxhumano. I-Resistance welding ihlanganisa i-spot welding, i-seam welding kanye ne-bolt welding.

Noma nini lapho kungenzeka, ukushisela kufanele kwenziwe esitolo lapho ikhwalithi yokushisela ngokuvamile iba ngcono, amashisela esitolo awekho ngaphansi kwesimo sezulu futhi ukufinyelela ekuhlanganyeleni kuvuleke kahle. Ama-welds angahlukaniswa ngokuthi ayisicaba, avundlile, aqondile, nangaphezulu. Kungabonakala ukuthi ama-welds ayisicaba yiwona okulula ukuwenza; ziyindlela ethandwayo. Ukushisela okungaphezulu, okuvame ukwenziwa ensimini, kufanele futhi kugwenywe lapho kungenzeka khona ngoba kunzima futhi kudla isikhathi, ngakho-ke kubiza kakhulu.

Ama-groove welds angangena kulungu elixhunyiwe ngengxenye yogqinsi lwelungu, noma angangena kugqinsi olugcwele lwelungu elixhunyiwe. Lokhu kubizwa ngokuthi ukungena kwe-partialjoint (PJP) kanye nokungena ngokuhlanganyela okuphelele (CJP), ngokulandelana . Amashisela okungena okuphelele (okubuye abizwe ngokuthi amashisela agcwele.penetration noma “'ipeni eligcwele”) ahlanganisa konke ukujula kweziphetho zamalungu axhumene Amashisela okungena okuyingxenye abiza kakhulu futhi asetshenziswa lapho imithwalo efakiwe ifana kangangokuthi i-weld engena ngokugcwele ayidingeki. Angasetshenziswa futhi lapho ukufinyelela ku-grooveis kukhawulelwe ohlangothini olulodwa lokuxhumeka.

Qaphela: I-Index TRUCTURAL STEEL DESIGN

Yiziphi izinzuzo zokushisela i-arc engaphansi kwamanzi?

I-arc welding engaphansi kwamanzi ilungele ukuzishintshanisa nendawo enevolumu ephezulu. Ingakwazi ukuqedela inani elikhulu lomsebenzi wokushisela ngesikhathi esifushane futhi ithuthukise ukusebenza kahle kokukhiqiza. I-arc welding engaphansi kwamanzi ilungele ukuzishintshanisa nendawo enevolumu ephezulu. Ingakwazi ukuqedela inani elikhulu lomsebenzi wokushisela ngesikhathi esifushane futhi ithuthukise ukusebenza kahle kokukhiqiza. I-arc welding engaphansi kwamanzi ijwayele ukusetshenziselwa ukushisela amashidi ensimbi aminyene ngoba ukungena kwawo okuphezulu kwamanje nokuphezulu kuwenza asebenze kangcono kulezi zinhlelo zokusebenza. Njengoba i-weld imbozwe yi-flux, i-oksijeni ingavinjelwa ngokuphumelelayo ekungeneni endaweni yokushisela, ngaleyo ndlela kuncishiswe amathuba okuba ne-oxidation kanye ne-spatter.Uma kuqhathaniswa nezinye izindlela zokuthungatha ama-manual, i-arc welding engaphansi kwamanzi ngokuvamile ingakwazi ukuzenzekelayo kalula, ukunciphisa izidingo eziphezulu zamakhono abasebenzi. Ekushiseleni kwe-arc engaphansi kwamanzi, izintambo eziningi zokushisela nama-arcs zingasetshenziswa ngesikhathi esisodwa ukuze kuzuzwe ukushisela kweziteshi eziningi (izingqimba eziningi) nokuthuthukisa ukusebenza kahle.

Yiziphi izinhlelo zokusebenza ze-Stainless Steel H zemishayo?

Imishayo yensimbi engagqwali H isetshenziswa kabanzi ekwakhiweni, kwezobunjiniyela basolwandle, okokusebenza kwezimboni, ezezimoto, amaphrojekthi wamandla, neminye imikhakha ngenxa yokumelana nokugqwala nokuqina kwayo. Banikeza ukwesekwa kwesakhiwo kumaphrojekthi wokwakha futhi badlala indima ebalulekile ezindaweni ezidinga ukumelana nokugqwala, njengendawo yasolwandle noma yezimboni. Ukwengeza, ukubukeka kwabo kwesimanje kanye nobuhle kubenza bafanelekele izinhlelo zokusebenza zezakhiwo nezangaphakathi.

Iqonde kangakanani insimbi ye-Stainless Steel HI?

Ukuqondisa kwensimbi engagqwali i-H-beam, njenganoma iyiphi ingxenye yesakhiwo, kuyisici esibalulekile ekusebenzeni nasekufakweni kwayo. Ngokuvamile, abakhiqizi bakhiqiza insimbi engagqwali i-H-imishayo enezinga elithile lokuqondisa ukuze bahlangabezane nezindinganiso zomkhakha kanye nokucaciswa.

Izinga elamukelekayo lemboni yokuqonda kunsimbi yesakhiwo, okuhlanganisa imishayo yensimbi engagqwali H, ngokuvamile lichazwa ngokwemibandela yokuchezuka okuvumelekile ukusuka kumugqa oqondile ngaphezu kobude obucacisiwe. Lokhu kuchezuka kuvame ukuvezwa ngokuya ngamamilimitha noma amayintshi okushanela noma ukusuka endaweni ebheke eceleni.

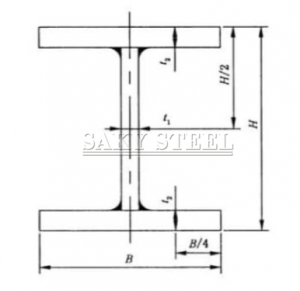

Isingeniso somumo we-H beam ?

Umumo we-cross-sectional we-I-beam steel, ovame ukwaziwa ngokuthi "工字钢" (gōngzìgāng) ngesi-Chinese, ufana nohlamvu oluthi "H" uma luvulwa. Ngokucacile, isigaba esiphambene ngokuvamile siqukethe amabha amabili avundlile (ama-flange) phezulu naphansi kanye nebha emaphakathi eqondile (iwebhu). Lo mumo othi "H" unikeza amandla aphakeme nokuzinza kwensimbi ye-I-beam, okwenza kube yinto evamile yesakhiwo ekwakhiweni nasebunjiniyela.Umumo oklanyelwe wensimbi ye-I-beam uyivumela ukuthi ifanelekele izinhlelo zokusebenza ezihlukahlukene zokuthwala nokusekela, njengemishayo, amakholomu, nezakhiwo zebhuloho. Lokhu kumiswa kwesakhiwo kuvumela insimbi ye-I-beam ukuthi isabalalise ngempumelelo imithwalo uma ingaphansi kwamandla, ihlinzeka ngokusekelwa okuqinile. Ngenxa yokuma kwayo okuyingqayizivele nezici zesakhiwo, insimbi ye-I-beam ithola ukusetshenziswa kabanzi emkhakheni wokwakha nobunjiniyela.

Ungawuveza kanjani usayizi nenkulumo ye-I-beam?

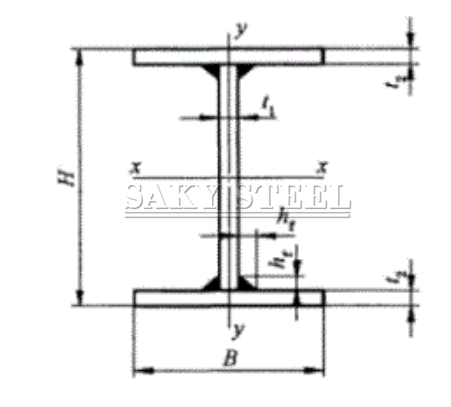

Ⅰ.Imifanekiso ephambanayo nezimpawu zokumaka zensimbi engagqwali engu-316L eshiselwe okumise okuka-H:

H——Ukuphakama

B——Ububanzi

t1——Ukujiya kwewebhu

t2——Ukujiya kwepuleti le-Flange

h£——Usayizi wokushisela(uma usebenzisa inhlanganisela yezinqe nefillet, kufanele kube usayizi womlenze wokushisela oqinisiwe ongu-hk)

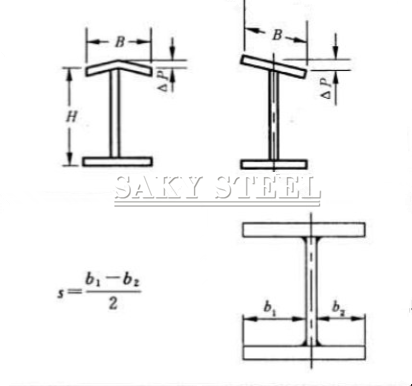

Ⅱ. Ubukhulu, umumo nokuchezuka okuvumelekile kwensimbi engu-2205 duplex eshiselwe okumise okuka-H:

| H Beam | Ukubekezelelana |

| I-thlckness (H) | Ukukhanya okungu-300 noma ngaphansi: 2.0 mmNgaphezu kuka-300:3.0mm |

| Ububanzi (B) | Ububanzi 2.0 mm |

| I-Perpendicularlty (T) | 1.2% noma ngaphansi kwe-wldth (B)Qaphela ukuthi ukubekezelela okuncane kungu-2.0 mm |

| I-offset yesikhungo (C) | Ububanzi 2.0 mm |

| Ukugoba | 0.2096 noma ngaphansi ubude |

| Ubude bomlenze (S) | [i-web plate thlckness (t1) x0.7]noma ngaphezulu |

| Ubude | 3 ~ 12m |

| Ukubekezelela ubude | + 40mm, 一0mm |

Ⅲ. Ubukhulu, umumo kanye nokuchezuka okuvumelekile kwensimbi eshiselwe okumise okuka-H

Ⅳ. Ubukhulu besigaba esiphambanayo, indawo ephambanayo, isisindo setiyori kanye nemingcele yesici eyisiphambano sensimbi eshiselwe okumise okuka-H

| Imishayo yensimbi engagqwali | Usayizi | Indawo Yesigaba (cm²) | Isisindo (kg/m) | Amapharamitha wesici | Usayizi we-Weld fillet h(mm) | ||||||||

| H | B | t1 | t2 | xx | yy | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1 021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25,15 | 1 331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1 046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1 735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1 916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 | 390 | 8.77 | 1 334 | 133 | 5,12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

Amakhasimende ethu

Impendulo Evela Kubathengi Bethu

I-Stainless Steel H Beams yizici zesakhiwo eziguquguqukayo ezakhiwe ngensimbi engagqwali yekhwalithi ephezulu. Lezi ziteshi zifaka umumo othi "H" ohlukile, onikeza amandla athuthukisiwe nokuzinza ezinhlelweni ezihlukahlukene zokwakha nezakhiwo.Isiphetho esihle nesiphucuziwe sensimbi engagqwali sinezela ukuthinta okuyinkimbinkimbi, okwenza le H Beam ifanelekele kokubili izakhi zedizayini ezisebenzayo nezikhangayo. Idizayini emise okwe-H ikhulisa amandla okuthwala umthwalo, okwenza lezi ziteshi ze-Steel zikwazi ukusekela ukwakhiwa kwezimboni futhi zenze lezi ziteshi ezisekelayo zikwazi ukuthola i-H efanelekile yokwakha imboni. izicelo ezimbonini ezehlukene, okuhlanganisa ezokwakha, ezokwakha, nezokukhiqiza, lapho ukusekelwa kwesakhiwo okuqinile kubalulekile.

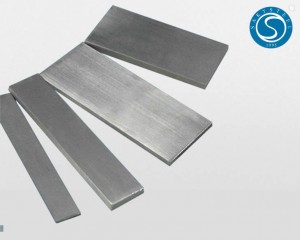

Ukupakisha kwe-Stainless Steel I Beams:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,