420 Ibha Eyisicaba Yensimbi Engagqwali

Incazelo emfushane:

I-Din 1.4034 SS 430 Flat Bars, SS UNS S42000 Flat Bars, Stainless Steel 420 Flat Bar, 420 Stainless Steel Cold Drawn Bars Suppliers e-China.

I-Grade 420 insimbi engagqwali iyinsimbi enekhabhoni ephezulu enokuqukethwe kwe-chromium okungenani okungu-12%. Njenganoma iyiphi enye insimbi engagqwali, ibanga 420 nalo lingaqiniswa ngokwelashwa okushisa. Inikeza i-ductility enhle esimweni sayo se-annealed kanye nezakhiwo ezinhle kakhulu zokumelana nokugqwala lapho insimbi ipholishwa, iphansi noma iqinisiwe. Leli banga linobulukhuni obuphakeme kakhulu - 50HRC - phakathi kwawo wonke amamaki ensimbi engagqwali ane-chromium engu-12%.

| 420 Stainless Steel Flat Bar Spections: |

| Ukucaciswa: | I-A276/484 / DIN 1028 |

| Okubalulekile: | 304 316 321 904L 410 420 2205 |

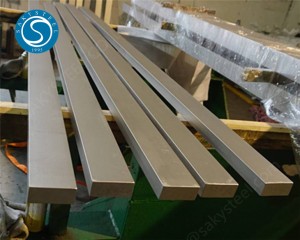

| I-Stainless Steel Round Bars: | Ububanzi bangaphandle busuka ku-4mm kuye ku-500mm |

| Ububanzi: | 1mm kuya ku-500mm |

| Ubukhulu: | 1mm kuya ku-500mm |

| Icebo: | Ishidi eligoqiwe elishisayo nelifakwe Pickled (HRAP) & elibandayo elidwetshiwe & eliqanjiwe & Sika Ishidi kanye nekhoyili |

| Ubude: | 3 kuya ku-6 Amamitha / 12 kuya ku-20 izinyawo |

| Ukumaka: | Usayizi, Ibanga, Igama Lokukhiqiza Kubha Ngayinye/Izingcezu |

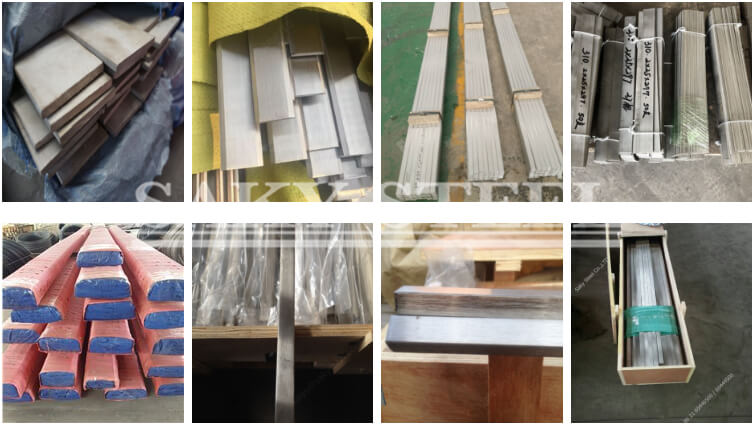

| Ukupakisha: | Ibha ngayinye yensimbi ine-singal, futhi eminingana izohlanganiswa isikhwama sokweluka noma njengemfuneko ngayinye. |

| I-Stainless Steel 420 Flat Bars Amabanga Alinganayo: |

| IZINGA | I-JIS | I-WERKSTOFF NR. | BS | AFNOR | I-SIS | I-UNS | AISI |

| I-SS 420 | I-SUS 420 | 1.4021 | 420S29 | - | 2303 | S42000 | 420 |

| SS 420I-Flat Bars Chemical Composition (i-saky steel): |

| Ibanga | C | Mn | Si | P | S | Cr | Ni | Mo |

| I-SUS 420 | 0.15 ubuningi | 1.0 ubuningi | 1.0 ubuningi | 0.040 ubuningi | 0.030 ubuningi | 12.0-14.0 | - | - |

| I-SS 420 Flat Bars Mechanical properties(insimbi esaky): |

| I-Empering Temperature (°C) | Amandla Okuqina (MPa) | Isivuno Amandla 0.2% Ubufakazi (MPa) | Ukwelula (% ku-50mm) | Ukuqina kweBrinell (HB) |

|---|---|---|---|---|

| Okufakiwe * | 655 | 345 | 25 | 241 ubuningi |

| 399°F (204°C) | 1600 | 1360 | 12 | 444 |

| 600°F (316°C) | 1580 | 1365 | 14 | 444 |

| 800°F (427°C) | 1620 | 1420 | 10 | 461 |

| 1000°F (538°C) | 1305 | 1095 | 15 | 375 |

| 1099°F (593°C) | 1035 | 810 | 18 | 302 |

| 1202°F (650°C) | 895 | 680 | 20 | 262 |

| * Izakhiwo ze-annealed tensile zijwayelekile ku-Condition A ye-ASTM A276; ubulukhuni be-annealed yilona esiphezulu esishiwo. | ||||

| Ukuqinisekisa Ikhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhidlizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlolwa kwe-Ultrasonic

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlaziywa komthelela

10. Ukuhlolwa Kokuhlola Kwe-Metallography

| Ukupakishwa: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,

Izicelo:

Izinhlelo zokusebenza ezidinga ukumelana nokugqwala okumaphakathi kanye nezakhiwo eziphakeme zomshini zilungele i-Alloy 420. Izibonelo zezinhlelo zokusebenza ezivame ukusetshenziswa i-Alloy 420 zifaka:

Cutlery

Ama-steam ne-gas turbine blades

Izitsha zasekhishini

Amabhawudi, amantongomane, izikulufu

Izingxenye zephampu nama-valve namashafti

Omata besitebhisi bami

Amazinyo kanye nezinsimbi zokuhlinza

Imilomo

Amabhola ensimbi aqinile nezihlalo zamaphampu omthombo kawoyela