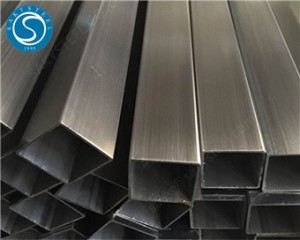

321 imicu yensimbi engagqwali

Incazelo emfushane:

| Imininingwane yeimichilo yensimbi engagqwali: |

Imininingwane :ASTM A240 / ASME SA240

Ibanga:321,321H, 430, 439, 441, 444

Ububanzi :8 - 600 mm

Ubukhulu :0.03 - 3mm

Ubuchwepheshe :Kushise kuginqike, Kugodole

Ukuqina:okuthambile, 1/4H, 1/2H, FH

I-Surface Finish :2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, hair line, sand blast, Brush, SATIN (Met with Plastic Coated) njll.

I-Raw Materail:POSCO, Acerinox, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, Saky Steel, Outokumpu

Ifomu :Amakhoyili, ama-Foil, amaRoll, ama-Strip, amaFlethi, njll.

| Insimbi Engagqwali 321/321H Ikhumula Amabanga Alinganayo: |

| IZINGA | I-WERKSTOFF NR. | I-UNS | I-JIS | EN |

| I-SS 321 | 1.4541 | I-S32100 | I-SUS 321 | I-X6CrNiTi18-10 |

| I-SS 321H | 1.4878 | I-S32109 | I-SUS 321H | I-X12CrNiTi18-9 |

| I-SS 321 / 321H Ihlubula Ukubunjwa Kwamakhemikhali kanye Nezakhiwo Zemishini: |

| Ibanga | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| I-SS 321 | 0.08 ubuningi | 2.0 ubuningi | 1.0 ubuningi | 0.045 ubuningi | 0.030 ubuningi | 17.00 - 19.00 | 0.10 ubuningi | 9.00 - 12.00 | 5(C+N) – 0.70 ubuningi |

| I-SS 321H | 0.04 - 0.10 | 2.0 ubuningi | 1.0 ubuningi | 0.045 ubuningi | 0.030 ubuningi | 17.00 - 19.00 | 0.10 ubuningi | 9.00 - 12.00 | 4(C+N) – 0.70 ubuningi |

| Ukuminyana | I-Melting Point | Amandla Okuqina | Amandla Esivuno (0.2%Offset) | Ukwelula |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| Kungani Ukhetha Thina : |

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

| Ukuqinisekisa Ikhwalithi Ye-SAKY STEEL (okuhlanganisa kokubili Okubhubhisayo Nokungabhidlizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlaziywa komthelela

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlolwa Kokuqina

10. Ukuhlolwa Kokuhlola Kwe-Metallography

| Iphakheji ye-SAKY STEEL'S: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,

Izicelo:

1. Imoto

2. Izinto zikagesi

3. Umzila Wezokuthutha

4. I-Precision Electronic

5. Amandla elanga

6. Isakhiwo kanye Nokuhlobisa

7. Isitsha

8. Ikheshi

9. Isitsha sasekhishini

10. Umkhumbi wokucindezela