316 Ipayipi lensimbi engenamthungo

Incazelo emfushane:

| Imininingwane yeinsimbi engagqwali ipayipi Seamless: |

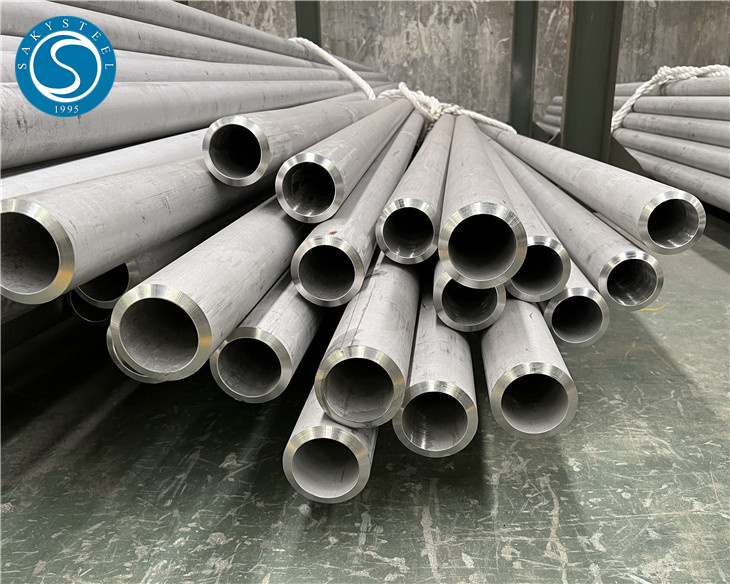

Amapayipi Angenamthungo nosayizi Wamashubhu :1 / 8″ NB – 24″ NB

Imininingwane :ASTM A/ASME SA213, A249, A269, A312, A358, A790

Okujwayelekile :ASTM, ASME

Ibanga:304, 316, 321, 321Ti, 420, 430, 446, 904L, 2205, 2507

Amasu:Kushiswe, kudonswe kubanda

Ubude :5.8M, 6M nobude obudingekayo

Ububanzi Bangaphandle :6.00 mm OD kufika ku-914.4 mm OD, Osayizi bafika ku-24” NB

Thickness :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Ishejuli :SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Izinhlobo :Amapayipi Angenamthungo

Ifomu :Round, Square, Rectangle, Hydraulic, Honed Tubes

Qeda :I-Plain End, I-Beveled End, Inyathelwe

| I-SS 316 Amapayipi Angenamthungo Ukwakhiwa Kwekhemikhali: |

| Ibanga | C | Mn | Si | P | S | Cr | Ni |

| I-SS316 | 0.08 ubuningi | 2 ubuningi | 0.75 ubuningi | 0.045 ubuningi | 0.030 ubuningi | 16-18 | 0.10 |

| I-Stainless Steel Pipe Mechanical Properties: |

| Ibanga | Amandla E-Tensile (MPa) min | Amandla Esivuno 0.2% Ubufakazi (MPa) min | Ubude (% ku-50mm) min | Ukuqina | |

| I-Rockwell B (HR B) ubuningi | I-Brinell (HB) ubuningi | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| Inqubo Yokukhiqiza Ipayipi Lensimbi Engagqwali : |

Lesi sithombe sibonisa okupheleleinqubo yokukhiqiza ipayipi engenamthungo, okuhlanganisa izigaba ezingu-8 ezibalulekile: ukulungiswa kwempahla eluhlaza, ukuthambisa, ukufakwa emanzini, ukugaya indawo engaphezulu, ukuhlanza i-asidi, ukudweba okubandayo, ukuhlolwa kwe-ultrasonic, nokupakishwa kokugcina. Isinyathelo ngasinye silawulwa ngokucophelela ukuze kuqinisekiswe ukunemba kobukhulu obuphezulu, ukuqedwa kwengaphezulu okuhle kakhulu, kanye nekhwalithi yangaphakathi, ehlangabezana nezidingo eziqinile zezinhlelo zokusebenza zezimboni.

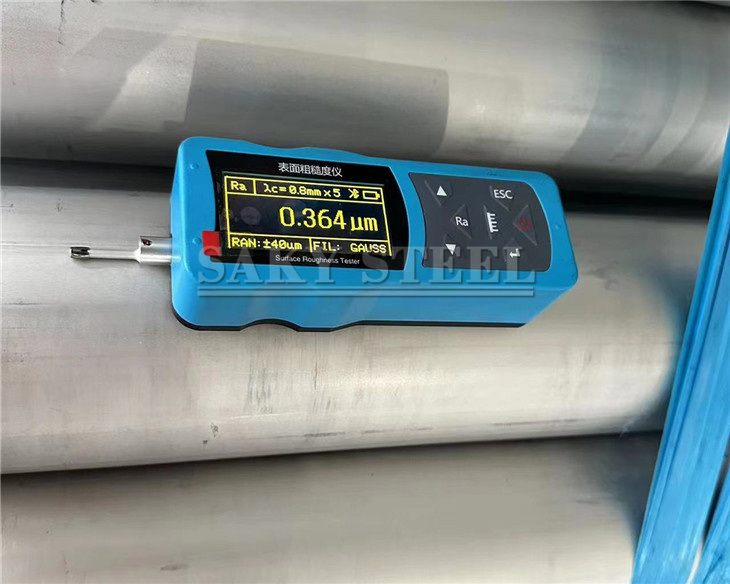

| Ukuhlolwa kwe-316 Stainless Steel Pipe Roughness : |

Kwa-SAKY STEEL senza ukuhlola okuqinile kokuqina kumapayipi ensimbi engagqwali ukuze siqinisekise indawo ebushelelezi futhi engaguquki ehlangabezana nezindinganiso zamazwe ngamazwe. Ukuma kwepayipi kuyisici esibalulekile esithinta ukumelana nokugqwala kokugeleza kanye nokusebenza okuphelele ezinhlelweni ezibucayi.

Sisebenzisa amathuluzi anembayo ukuze silinganise amanani amaholo angaphezulu siqinisekisa ukuthi wonke amapayipi ahlangabezana nezidingo zekhasimende ukuze abushelelezi futhi aqedele. Amapayipi ethu alungele ukucubungula ukudla kwamakhemikhali ezimbonini zasolwandle nezakhiwo lapho ikhwalithi yendawo ibalulekile.

|  |

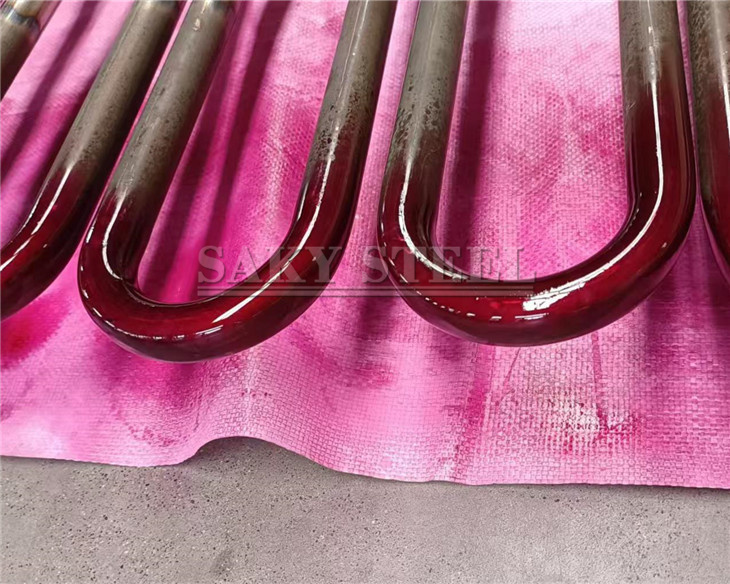

| I-Stainless Steel Pipe Surface Test: |

Ukuqedwa kwamapayipi ensimbi engagqwali kubalulekile ekusebenzeni nokubukeka. Kwa-SAKY STEEL silawula ngokuqinile ikhwalithi yendawo ngezinqubo zokuhlola ezithuthukile. Isithombe sibonisa ukuqhathanisa okucacile phakathi kwamapayipi angaphezulu amabi anamaphutha abonakalayo namapayipi ethu amahle angaphezulu anobushelelezi futhi afanayo.

Amapayipi ethu ensimbi engagqwali awanawo imihuzuko yemigodi kanye nezimpawu zokushisela eziqinisekisa ukumelana nokugqwala okuhle kakhulu nokwethembeka. Lawa mapayipi asetshenziswa kakhulu kumakhemikhali asolwandle kanye nezakhiwo lapho ubuqotho bomhlaba bubalulekile.

| Ukuhlolwa kwe-PT : |

I-SAKY STEEL yenza ukuhlola kwe-PT okungenelayo kumapayipi ensimbi engagqwali nezingxenye njengengxenye yenqubo yethu yokulawula ikhwalithi eqinile. I-PT iyindlela yokuhlola engacekeli phansi esetshenziselwa ukuthola amaphutha angaphezulu njengokuqhekeka kwe-porosity kanye nezinto ezifakiwe ezingabonakali ngeso lenyama.

Abahloli bethu abaqeqeshiwe basebenzisa izinto zokungena zekhwalithi ephezulu nezikanjiniyela ukuze baqinisekise imiphumela enembile nethembekile. Zonke izinqubo ze-PT zilandela izindinganiso zamazwe ngamazwe kanye nokucaciswa kwamakhasimende okuqinisekisa ukuphepha nokusebenza komkhiqizo.

|  |

| Kungani Ukhetha Thina : |

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

| Ukuqinisekisa Ikhwalithi (okuhlanganisa kokubili Okubhubhisayo Nokungabhizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Isivivinyo esikhulu

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Flaring Testing

8. Ukuhlolwa kweJet-Wamanzi

9. Isivivinyo Esingena Ngaphakathi

10. Ukuhlolwa kwe-X-ray

11. I-Intergranular Corrosion Testing

12. Ukuhlaziywa komthelela

13. Eddy ukuhlolwa kwamanje

14. Ukuhlaziywa kwe-Hydrostatic

15. Ukuhlolwa Kokuhlola Kwe-Metallography

| Ukupakishwa: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho izimpahla zidlula eziteshini ezihlukahlukene ukuze zifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,

Izicelo:

1. Izinkampani zephepha & Pulp

2. Izicelo Zokucindezela Okuphezulu

3. Imboni Kawoyela Negesi

4. I-Chemical Refinery

5. Ipayipi

6. Isicelo Sezinga Lokushisa Eliphezulu

7. Ipayipi Lamanzi Lin

8. Izitshalo Zamandla Enuzi

9. Izimboni Zokugaya Ukudla kanye Nezobisi

10. I-Boiler & Heat Exchangers