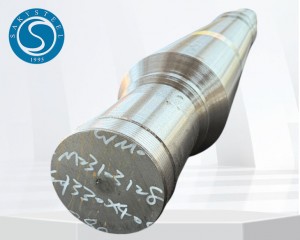

316 Forging Steel Roller Shaft

Incazelo emfushane:

Thola Forging Steel Roller Shafts izicelo zezimboni. Kwenziwe ngokwezifiso ekucacisweni kwakho, nokusebenza okuhlala isikhathi eside nokufoja okunembayo.

I-Forged Steel Roller Shaft

I-Forged Steel Roller Shaftiyingxenye yamandla aphezulu, ehlala isikhathi eside esetshenziswa ezinhlelweni ezihlukene zezimboni, ikakhulukazi ekwenzeni nasekucubunguleni izinto ezifana nensimbi, iphepha, nezindwangu. Ekhiqizwe ngenqubo yokubumba, lawa mashafu anikezela ngezakhiwo ezisezingeni eliphezulu, okuhlanganisa ukuqina okuthuthukisiwe, ukumelana nokuguga, namandla aphakeme okuthwala uma kuqhathaniswa namashafti asakazwayo noma omshini. Ama-Forged Steel Roller Shafts enziwe ngokwezifiso ukuze ahlangabezane nosayizi othize, umumo, nezidingo zokusebenza, okuqinisekisa ukusebenza okuthembekile nempilo yesevisi eyandisiwe ezindaweni ezisindayo. Ilungele ukusetshenziswa kumarola, amaconveyor, neminye imishini, ihlinzeka ngokusebenza okukhethekile ezimeni ezinengcindezi ephezulu.

Imininingwane Yama-Forged Steel Rolls:

| Imininingwane | I-ASTM A182,ASTM A105,GB/T 12362 |

| Okubalulekile | Insimbi ye-alloy, insimbi ye-Carbon, insimbi ye-Carburizing, insimbi ecishiwe nethambile |

| Ibanga | I-Carbon Steel:4130,4140,4145,S355J2G3+N,S355NL+N,C20,C45,C35, njll. |

| Insimbi Engagqwali:17-4 PH, F22,304,321,316/316L, njll. | |

| Insimbi Yensimbi:D2/1.2379,H13/1.2344,1.5919, njll. | |

| I-Surface Qeda | Okumnyama, Okukhanyayo, njll. |

| Ukwelashwa kokushisa | Ukujwayela,Ukukhipha,Ukucima&Ukushisa, Ukucisha ubuso,Ukuqina kwekesi |

| Ukwenza imishini | I-CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling |

| Gear Machining | I-Gear Hobbing, i-Gear Milling, i-CNC Gear Milling, Ukusika igiya, ukusika igiya elivunguzayo, Ukusika kwegiya |

| Isitifiketi Sokuhlolwa Kwemishini | EN 10204 3.1 noma EN 10204 3.2 |

Ukuqamba Izicelo Ze-Steel Shaft:

1.Imboni Yensimbi: Ama-Forged Steel Roller Shafts asetshenziswa kakhulu ezigayweni, lapho edlala indima ebalulekile ekubumbeni nasekwakheni imikhiqizo yensimbi. Lezi shaft zimelana namandla aphezulu kanye namazinga okushisa, ziqinisekisa ukucubungula kwensimbi okubushelelezi nokungaguquguquki.

2.Imboni Yamaphepha Ne-Pulp: Ezimbonini zephepha, lezi shaft zisetshenziswa kuma-calender, emishinini yokunyathelisa, nama-roller, abalulekile ekukhiqizeni iphepha namakhadibhodi. Ukuqina kwazo kanye nokumelana kwazo nokugqoka kuzenza zilungele ukuphatha imisebenzi enengcindezi ephezulu kanye nesivinini esikhulu.

3.Imboni Yezinto Zokuthunga: Ama-Forged Steel Roller Shaft asetshenziswa emishinini yendwangu, njengokuluka nokuphotha imishini, ukusekela amarola nokuhlinzeka ukunyakaza okunembile nokuzinza ngesikhathi sokukhiqizwa kwendwangu.

4. Ukumbiwa kanye Nokukwalilwa: Le migodi ibalulekile emishinini egaya amaminerali, lapho ibekezelela imithwalo esindayo kanye nezimo zokusebenza ezinzima. Amandla abo aqinisekisa ukwethembeka kwesikhathi eside nokusebenza kahle kuma-crusher, izigayo, nama-conveyors.

5.Izisetshenziswa Zokulima: Emishinini yezolimo, enjengabavuna nababhulayo, Ama-Forged Steel Roller Shafts asiza ekudluliseni nasekuhambiseni izinto ezisetshenziswayo, ukuqinisekisa ukusebenza kahle kwezinto zokusebenza ngaphansi kwezimo zensimu ezidinga kakhulu.

6.Izinhlelo Zezimoto Nezokuthutha: Izigxobo Zensimbi Ezenziwayo zisetshenziswa emigqeni yokukhiqiza izimoto kanye nezinhlelo zokuthutha, lapho zinikeza ukwesekwa okuqinile kwamarola anesisindo esinzima ahambisa imikhiqizo eduze komugqa wokuhlanganisa.

I-7.I-Plastic and Rubber Manufacturing: Lezi shafts zisetshenziswa emishinini yokukhishwa kanye nezinye izinto zokucubungula ezimbonini zepulasitiki nezenjoloba, ukuqinisekisa ukusebenza okuphezulu ezindaweni lapho isivinini esingaguquki kanye nokuthwala umthwalo kuyadingeka.

Izici ze-Bright Shaft Forgings:

1.Amandla Aphezulu Nokuqina: Inqubo yokubumba ithuthukisa ukwakheka kwensimbi okusanhlamvu kwangaphakathi, okwenza i-shaft iqine kakhulu futhi ikwazi ukumelana nengcindezi nomthelela.

2.Improved Wear Resistance:Forged Steel Roller Shafts amelana kakhulu nokugqokwa nokuhuzuka, okuwenza alungele izinhlelo zokusebenza ezinzima lapho ukungqubuzana kungapheli.

3.Ukumelana Nokukhathala Okuthuthukisiwe:Ngenxa yesakhiwo sawo esincane esicwengisisiwe, la mashafu angakwazi ukumelana nokulayisha nokuthulula imijikelezo ngaphandle kokuphuka noma ukulahlekelwa ubuqotho.

I-4.I-Superior Load-Bearing Capacity:I-Forged Steel Roller Shafts yakhelwe ukuphatha imithwalo esindayo ngaphandle kokuguqulwa.

5.Ukumelana Nokugqwala:Kuya ngebanga lensimbi esetshenzisiwe kanye nanoma yikuphi ukwelapha okwengeziwe kwendawo (isb, ukumbozwa noma ukwelapha ukushisa).

6.I-Customizability:I-Forged Steel Roller Shafts ingalungiselelwa ukuhlangabezana nosayizi othize, umumo, kanye nezidingo zokusebenza.

I-7.High Temperature Resistance: Lawa mashafu angakwazi ukusebenza ezimweni zokushisa ezeqisayo.

8.Ukunemba Kobukhulu:Inqubo yokubumba ivumela ukubekezelelana okuqinile kanye nokunemba okuphezulu kwe-dimensional.

9.Ukuqina Nokuphila Isikhathi Eside:Ama-Forged Steel Roller Shafts anempilo ende yesevisi uma kuqhathaniswa nezinye izinto zokwakha noma izindlela zokukhiqiza ngenxa yamandla awo aphezulu nokuqina.

10.Ukumelana Nomthelela:Inqubo yokufoja ithuthukisa ikhono le-shaft lokumelana nokushaqeka okungazelelwe noma imithelela.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS, TUV, BV 3.2.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Ukupakisha Izigxobo Zensimbi Ezenziwa:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho izimpahla zidlula eziteshini ezihlukahlukene ukuze zifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakishwa.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,