Ⅰ.Ingcamango esisiseko yonyango lobushushu.

A.Ingcamango esisiseko yonyango lobushushu.

Izinto ezisisiseko kunye nemisebenzi yeunyango lobushushu:

1.Ukufudumeza

Injongo kukufumana iyunifomu kunye nesakhiwo esihle se-austenite.

2.Ukubamba

Injongo kukuqinisekisa ukuba i-workpiece ishushu ngokucokisekileyo kunye nokuthintela i-decarburization kunye ne-oxidation.

3.Ukupholisa

Injongo kukuguqula i-austenite ibe yi-microstructures eyahlukeneyo.

IiMicrostructures emva koNyango loBubushushu

Ngethuba lenkqubo yokupholisa emva kokufudumeza nokubamba, i-austenite iguqulela kwii-microstructures ezahlukeneyo kuxhomekeke kwizinga lokupholisa. Ii-microstructures ezahlukeneyo zibonisa iimpawu ezahlukeneyo.

B.Ingcamango esisiseko yonyango lokushisa.

UHlelo oluSekwe kwiiNdlela zokuFundisa kunye nokuPholisa, kunye neMicrostructure kunye neePropati zeNsimbi

1. Unyango loBushushu oluQhelekileyo (uNyango loBubushushu lulonke):Ubushushu, ukufakwa, ukuQinisa, ukucima

2.UNyango loBubushushu boMphezulu: Ukucinywa koMphezulu, Ukucima uMgangatho wokuFudumeza, Ukucima uMphezulu woMbane wokuFudumeza, Ukucima uMbane woMbane wokuFundisa.

3. Unyango lobushushu beChemical: Carburizing, Nitriding, Carbonitriding.

4.Olunye uNyango loBubushushu: UNyango loBubushushu obuLawulwayo, uNyango loBubushushu be-Vacuum, unyango loBushushu.

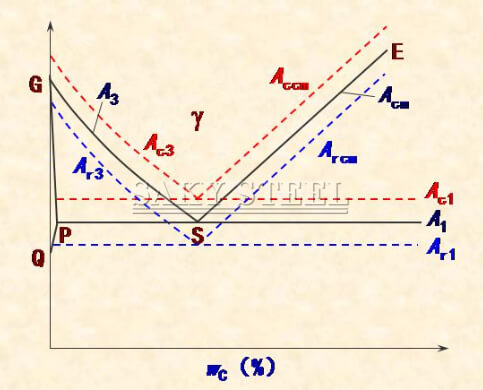

C.Critical Temperature of Steels

Ubushushu benguqu ebalulekileyo yentsimbi sisiseko esibalulekileyo sokumisela ukufudumeza, ukubamba, kunye neenkqubo zokupholisa ngexesha lonyango lokushisa. Ichongwa ngumzobo wesigaba se-iron-carbon.

Isiphelo esingundoqo:Olona tshintsho lubalulekileyo lobushushu bentsimbi luhlala lushiyeka emva kweqondo lobushushu lethiyori. Oku kuthetha ukuba ukufudumala kuyadingeka ngexesha lokufudumala, kwaye ukupholisa ngaphantsi kuyimfuneko ngexesha lokupholisa.

Ⅱ.Annealing kunye Normalizing of Steel

1. Inkcazo ye-Anealing

I-Anealing ibandakanya ukufudumeza intsimbi kwiqondo lokushisa elingaphezulu okanye ngaphantsi kwendawo ebalulekileyo ye-Ac₁ ukuyibamba kuloo bushushu, kwaye emva koko uyipholise ngokukhawuleza, ngokuqhelekileyo ngaphakathi kwesithando somlilo, ukufezekisa isakhiwo esisondeleyo kwi-equilibrium.

2. Injongo yokuHlola

①Lungisa Ukuqina koMachining: Ukufezekisa ubulukhuni obunobuqili kuluhlu lwe-HB170 ~ 230.

②Ukunciphisa uxinzelelo lweNtsalela: Ikhusela ukuguqulwa okanye ukuqhekeka ngexesha leenkqubo ezilandelayo.

③Cokisa uLwakhiwo lweenkozo: Luphucula ubume obuncinci.

④Amalungiselelo oNyango lokuGqibela ubushushu: Ufumana i-granular (spheroidized) pearlite yokucima kunye nokuvutha okulandelayo.

3.Spheroidizing Annealing

Iinkcukacha ngeNkqubo: Iqondo lobushushu likufuphi nendawo ye-Ac₁.

Injongo: Ukwenza i-spheroidize i-cementite okanye i-carbides kwintsimbi, ekhokelela kwi-granular (spheroidized) pearlite.

Uluhlu olusebenzayo: Isetyenziselwa iintsimbi ezineeutectoid kunye ne-hypereutectoid compositions.

4.Ukwahlula iAnealing (i-Homogenizing Annealing)

Iinkcukacha zeNkqubo: Ubushushu bokufudumala bungaphantsi kancinane komgca we-solvus kumzobo wesigaba.

Injongo: Ukuphelisa ulwahlulo.

①Ophantsi-carbon steelkunye nomxholo wekhabhoni ongaphantsi kwe-0.25%, i-normalization ikhethwa ngaphezu kwe-annealing njengonyango lokulungiselela ubushushu.

②Kwiintsimbi ephakathi kwekhabhoni enomxholo wekhabhoni phakathi kwe-0.25% kunye ne-0.50%, nokuba i-annealing okanye i-normalization ingasetyenziswa njengonyango lokulungiselela ubushushu.

③Kwiintsimbi ephakathi ukuya kwikhabhoni ephezulu enomxholo wekhabhoni phakathi kwe-0.50% kunye ne-0.75%, kucetyiswa ukuba kufakwe i-annealing epheleleyo.

④Kuphezulu-carbon steelngomxholo wekhabhoni omkhulu kune-0.75%, i-normalization isetyenziselwa kuqala ukuphelisa inethiwekhi ye-Fe₃C, ilandelwa yi-spheroidizing annealing.

Ⅲ.Ukucinywa kunye nokuTshiswa kweNsimbi

A.Ukucima

1. Inkcazo yokuCima: Ukucima kubandakanya ukufudumeza intsimbi kwiqondo elithile lobushushu ngaphezu kwe-Ac₃ okanye indawo ye-Ac₁, ukuyibamba kwelo qondo lokushisa, kwaye emva koko uyipholise ngesantya esikhulu kunezinga lokupholisa elibalulekileyo ukwenza i-martensite.

2. Injongo yokuCima: Injongo ephambili kukufumana i-martensite (okanye ngamanye amaxesha i-bainite ephantsi) ukwandisa ubunzima kunye nokuxhatshazwa kokugqoka kwentsimbi. Ukucima enye yezona nkqubo zibalulekileyo zonyango lobushushu kwintsimbi.

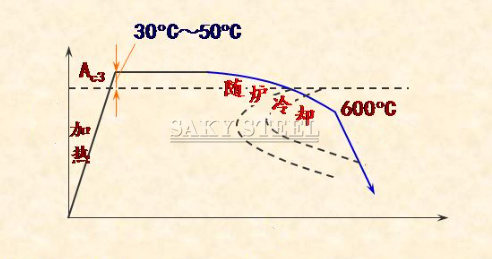

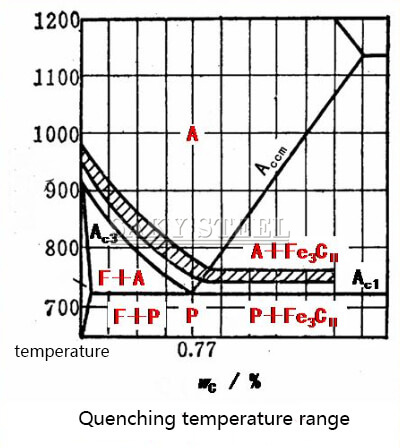

3.Ukumisela amaqondo obushushu okucinywa kwiintlobo ezahlukeneyo zentsimbi

Intsimbi yeHypoeutectoid: Ac₃ + 30°C ukuya kuma-50°C

I-Eutectoid kunye ne-Hypereutectoid Steel: Ac₁ + 30°C ukuya ku-50°C

I-Alloy Steel: i-50 ° C ukuya kwi-100 ° C ngaphezu kweqondo lokushisa elibalulekileyo

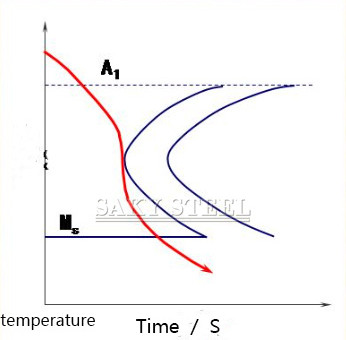

4. Iimpawu zokuPholisa zeNdawo eLungileyo yokuCima:

Ukupholisa okucothayo phambi kobushushu bempumlo: Ukunciphisa ngokwaneleyo uxinzelelo lwe-thermal.

Ukupholisa okuPhakamileyo koMmandla kufutshane ne "Nose" Ubushushu: Ukuphepha ukubunjwa kwezakhiwo ezingezizo ze-martensitic.

Ukupholisa okucothayo Kufuphi ne-M₅ Indawo: Ukunciphisa uxinzelelo olubangelwa yinguqu ye-martensitic.

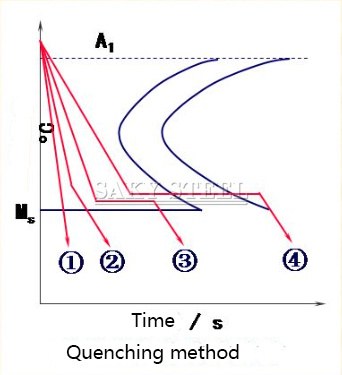

5. Iindlela zokucima kunye neempawu zazo:

① Ukucinywa okuLula: Kulula ukuyisebenzisa kwaye ilungele amaqhekeza amancinci, alula. Isiphumo se-microstructure yi-martensite (M).

②Ukucinywa okuphindwe kabini: Kunzima ngakumbi kwaye kunzima ukulawula, kusetyenziselwa intsimbi emile okwekhabhoni ephezulu kunye nentsimbi enkulu yealloy workpieces. I-microstructure enesiphumo yi-martensite (M).

③Ukucinywa okwaphukileyo: Inkqubo entsokothileyo, esetyenziselwa izinto ezinkulu, ezimile okwentsimbi yealloyi. I-microstructure enesiphumo yi-martensite (M).

④Ukucinywa kwe-Isothermal: Isetyenziselwa izinto ezincinci, ezinobumba obuntsonkothileyo kunye neemfuno eziphezulu. I-microstructure enesiphumo isezantsi kwe-bainite (B).

6.Izinto ezichaphazela ukuqina

Umgangatho wobunzima buxhomekeke ekuzinzeni kwe-austenite epholileyo kwintsimbi. Ukuphakama kozinzo lwe-austenite epholileyo, kungcono ukuqina, kwaye ngokuphambene noko.

Izinto eziphembelela ukuzinza kwe-Supercooled Austenite:

Isikhundla seC-Curve: Ukuba i-C-curve ishintshela ngasekunene, izinga lokupholisa elibalulekileyo lokucima liyancipha, liphucula ukuqina.

Isiphelo esingundoqo:

Nayiphi na into eguqula i-C-curve ukuya ngasekunene yandisa ukuqina kwentsimbi.

Umba ongundoqo:

Ukubunjwa kweMichiza: Ngaphandle kwe-cobalt (Co), zonke izinto ze-alloying ezichithwe kwi-austenite zandisa ukuqina.

Ukusondela komxholo wekhabhoni kukubunjwa kwe-eutectoid kwi-carbon steel, ngakumbi i-C-curve itshintshela ngasekunene, kwaye iphezulu ukuqina.

7.Ukuzimisela kunye nokuMelelwa koBulukhuni

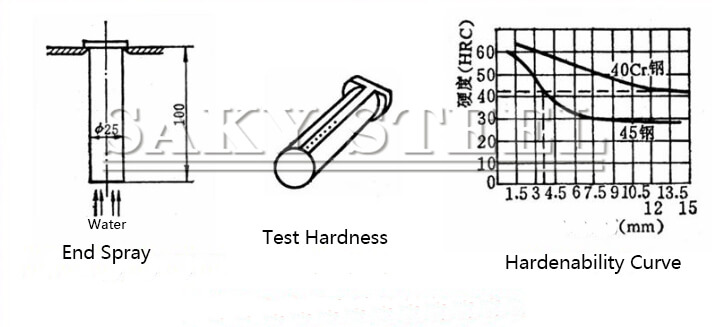

①Ukuphela kovavanyo lokuqina: Ukuqina kulinganiswa kusetyenziswa indlela yokuvavanya ukuphela kokucima.

②I-Critical Quench Diameter Method: I-diameter yokucima okubalulekileyo (D₀) imele ubukhulu obukhulu bentsimbi enokuthi iqiniswe ngokupheleleyo kwindawo ethile yokucima.

B. Ukuthoba

1. Inkcazo ye-Tempering

I-Tempering yinkqubo yokunyanga ukushisa apho intsimbi ecinyiweyo iphinda ihlaziywe kwiqondo lokushisa elingaphantsi kwe-A₁ point, egcinwe kuloo bushushu, kwaye ipholile kwiqondo lokushisa.

2. Injongo yokuthoba

Ukunciphisa okanye Ukuphelisa Ukuxinezeleka okushiyekileyo: Kunqanda ukuguqulwa okanye ukuqhekeka kwendawo yokusebenza.

Nciphisa okanye Uphelise iResidual Austenite: Uzinzisa imilinganiselo yendawo yokusebenza.

Ukuphelisa ubuNcinci bentsimbi ecinyiweyo: Lungisa i-microstructure kunye neepropati ukuhlangabezana neemfuno zomsebenzi.

Inqaku elibalulekileyo: Intsimbi kufuneka ishushu ngokukhawuleza emva kokucima.

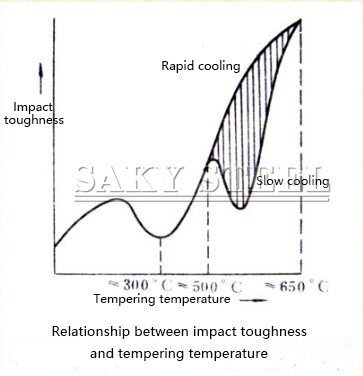

3.Iinkqubo zokuthambisa

1.Ubushushu obuphantsi

Injongo: Ukunciphisa uxinzelelo lokucima, ukuphucula ukuqina komsebenzi, kunye nokufezekisa ubunzima obuphezulu kunye nokumelana nokunxiba.

Ubushushu: 150°C ~ 250°C.

Ukusebenza: Ubunzima: HRC 58 ~ 64. Ubunzima obuphezulu kunye nokuxhatshazwa kokugqoka.

Izicelo: Izixhobo, iimolds, iibheringi, iinxalenye ze-carburized, kunye nezixhobo eziqiniswe phezulu.

2.Ubushushu obuphezulu

Injongo: Ukufezekisa ukuqina okuphezulu kunye namandla okwaneleyo kunye nobunzima.

Ubushushu: 500°C ~ 600°C.

Ukusebenza: Ukuqina: HRC 25 ~ 35. Iipropati ezilungileyo zoomatshini zizonke.

Izicelo: I-Shafts, iigiyeri, iintonga zokudibanisa, njl.

Ukucokisa iThermal

Ingcaciso: Ukucima okulandelwa bubushushu obuphezulu kubizwa ngokuba kukucokisa i-thermal, okanye ukufudumeza nje ngokulula. Intsimbi ephathwayo yile nkqubo inomsebenzi ogqwesileyo jikelele kwaye isetyenziswa ngokubanzi.

Ⅳ.UNyango loBubushushu boMphezulu beNsimbi

A. Ukucinywa komphezulu kweentsimbi

1. Inkcazo yokuQiniswa koMphezulu

Ukuqina komphezulu yinkqubo yonyango lobushushu eyilelwe ukomeleza umaleko womphezulu wesixhobo sokusebenza ngokuwufudumeza ngokukhawuleza ukuguqula umaleko womphezulu ube yi austenite kwaye emva koko uyipholise ngokukhawuleza. Le nkqubo iqhutyelwa ngaphandle kokuguqula ukubunjwa kweekhemikhali zensimbi okanye isakhiwo esisisiseko sezinto eziphathekayo.

2. Izinto ezisetyenziselwa ukuQinisa uMphezulu kunye neSakhiwo se-Post-Hardening

Izixhobo ezisetyenziselwa ukwenza lukhuni umphezulu

Izinto eziqhelekileyo: Intsimbi yekhabhoni ephakathi kunye nentsimbi ye-carbon alloy ephakathi.

Unyango lwangaphambili:Inkqubo eqhelekileyo: Ukuthoba. Ukuba iipropati eziphambili azibalulekanga, i-normalizing ingasetyenziswa endaweni yoko.

Ulwakhiwo lwasemva kokuqina

Ulwakhiwo lomphezulu: Umaleko womphezulu udla ngokwenza ulwakhiwo oluqinileyo olufana nemartensite okanye ibainite, olubonelela ngobulukhuni obuphezulu kunye nokunganyangeki.

Isakhiwo esingundoqo: Ingundoqo yentsimbi ngokuqhelekileyo igcina isakhiwo sayo sokuqala, njenge-pearlite okanye i-tered state, kuxhomekeke kwinkqubo yonyango lwangaphambili kunye neempawu zesiseko. Oku kuqinisekisa ukuba ingundoqo igcina ukuqina okulungileyo kunye namandla.

B.Iimpawu zokwenziwa lukhuni komphezulu

I-1.Ukushisa okuPhakamisayo kunye nokuPhakamisa okuPhakamisayo: Ukuqina komphezulu we-Induction ngokuqhelekileyo kubandakanya ukushisa okuphezulu kunye nokufudumeza ngokukhawuleza, okuvumela ukufudumeza ngokukhawuleza ngexesha elifutshane.

I-2.I-Fine Austenite Grain Structure kwi-Surface Layer: Ngethuba lokufudumeza ngokukhawuleza kunye nenkqubo yokucinywa okulandelayo, i-surface layer yenza iinkozo ezintle ze-austenite. Emva kokucima, umphezulu ngokuyintloko uqulathe i-martensite ecolekileyo, enobulukhuni obuqhelekileyo obuyi-2-3 HRC ephezulu kunokucima okuqhelekileyo.

3.Umgangatho woMphezulu oLungileyo: Ngenxa yexesha elifutshane lokufudumeza, umphezulu womsebenzi awukho lula kwi-oxidation kunye ne-decarburization, kunye ne-deformation eyenziwe ngokucimayo iyancitshiswa, iqinisekisa umgangatho omhle womphezulu.

I-4.Amandla aphezulu oFatigue: Ukuguqulwa kwesigaba se-martensitic kwi-surface layer ivelisa uxinzelelo oluxinzelelekileyo, okwandisa amandla okukhathala kwe-workpiece.

I-5.Ubuchule boMveliso oPhezulu: Ukuqina komphezulu we-Induction kukulungele ukuveliswa kobuninzi, ukunika ukusebenza kakuhle okuphezulu.

C.Ukuhlelwa konyango lobushushu beekhemikhali

Ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, ukungcwatywa, iSiliconizing, iSiliconizing

D.Gas Carburizing

I-Gas Carburizing yinkqubo apho i-workpiece ibekwe kwisithando somlilo esitywiniweyo segesi kwaye sifudunyezwe kwiqondo lobushushu eliguqula intsimbi ibe yi-austenite. Emva koko, i-arhente ye-carburizing ithontsizwa eziko, okanye umoya we-carburizing waziswa ngokuthe ngqo, uvumela iiathom zekhabhoni ukuba zisasazeke kumaleko ongaphezulu wesixhobo sokusebenza. Le nkqubo yonyusa umxholo wekhabhoni (wc%) kumphezulu womsebenzi.

√Abameli beCarburizing:

•Iigesi ezityebile ngeCarbon: Ezinje ngerhasi yamalahle, i-liquefied petroleum gas (LPG), njl.

•Ulwelo lwe-Organic: Njenge-kerosene, i-methanol, ibenzene, njl.

√IiParameters zeNkqubo yeCarburizing:

•Ubushushu beCarburizing: 920~950°C.

• Ixesha lokungcwatywa kwe-carburizing: Kuxhomekeke kubunzulu obunqwenelekayo bomaleko we-carburized kunye neqondo lobushushu lokungcwaba.

E.Heat Unyango Emva Carburizing

Intsimbi kufuneka ifumane unyango lobushushu emva kokungcwatywa kwe-carburizing.

Inkqubo yoNyango loBubushushu emva kokungcwatywa kweCarburizing:

√Ukucima + Ubushushu obuphantsi

1.Ukucinywa okuthe ngqo emva kokupholisa kwangaphambili + ubushushu obuphantsi: I-workpiece ipholiswe kwangaphambili ukusuka kwiqondo lokushisa le-carburizing ukuya ngaphezu kweqondo lokushisa eliphambili le-Ar₁ kwaye ngoko nangoko yacinywa, ilandelwa ngubushushu obuphantsi kwi-160 ~ 180 ° C.

2.Ukucinywa okukodwa emva kokupholisa kwangaphambili + ubushushu obuphantsi: Emva kokungcwatywa kwe-carburizing, i-workpiece ipholiswa kancinci ukuya kwiqondo lobushushu begumbi, ize iphinde ifudunyezwe ukucinywa kunye nobushushu obuphantsi.

3. Ukucinywa kabini emva kokuPholisa kwangaphambili + Ukushisa okuphantsi: Emva kokutshisa i-carburizing kunye nokucotha okucothayo, i-workpiece idlula izigaba ezibini zokufudumeza kunye nokucima, kulandelwa ukushisa okuphantsi.

Ⅴ.Unyango lobushushu beChemical yeeNsimbi

1.Inkcazo yoNyango lweMichiza yokushisa

Unyango lobushushu beMichiza yinkqubo yonyango lobushushu apho i-workpiece yentsimbi ibekwe kwindawo ethile esebenzayo, ifudunyezwe, kwaye ibanjwe kwiqondo lokushisa, ivumela ii-athomu ezisebenzayo phakathi ukuba zisasazeke kumphezulu we-workpiece. Oku kutshintsha ukubunjwa kweekhemikhali kunye ne-microstructure yendawo yokusebenza, ngaloo ndlela iguqula iimpawu zayo.

I-2.Inkqubo esisiseko yoNyango lwe-Chemical Heat

Ukubola: Ngexesha lokufudumala, i-medium esebenzayo iyabola, ikhuphe ii-athomu ezisebenzayo.

Ukufunxa: Ii-athomu ezisebenzayo zibhengezwa ngumphezulu wentsimbi kwaye zinyibilike kwisisombululo esiqinileyo sentsimbi.

Ukusasazwa: Iiathom ezisebenzayo ezifunxayo nezinyibilikayo kumphezulu wentsimbi zifudukela ngaphakathi.

Iindidi ze-Induction Surface Ukuqina

a.High-Frequency Induction Heating

Izanziso zangoku: 250 ~ 300 kHz.

Ubunzulu boMaleko oQinisiweyo: 0.5 ~ 2.0 mm.

Izicelo: Iigiya zemodyuli eziphakathi nezincinci kunye neeshafts ezincinci ukuya eziphakathi.

b.Medium-Frequency Induction Heating

Izanziso zangoku: 2500 ~ 8000 kHz.

Ubunzulu boMaleko Obulukhuni: 2 ~ 10 mm.

Usetyenziso: Ishafti ezinkulu kunye neemodyuli ezinkulu ukuya kweziphakathi.

c.Power-Frequency Induction Heating

Izanziso zangoku: 50 Hz.

Ubunzulu boMaleko Obulukhuni: 10 ~ 15 mm.

Usetyenziso: Izixhobo zokusebenza ezifuna umaleko onzulu kakhulu lukhuni.

3. I-Induction Surface Ukuqina

UmGaqo oSisiseko wokuQinisekisa uMphezulu woMveliso

Impembelelo yolusu:

Xa i-alternating current kwi-coil induction induces current on the surface of the workpiece, ininzi ye-current induced igxininiswe kufuphi nomphezulu, ngelixa phantse akukho okwangoku kudlula ngaphakathi kwendawo yokusebenza. Le nto yaziwa ngokuba yimpembelelo yesikhumba.

UmGaqo wokuQinisekisa uMphezulu woMphezulu:

Ngokusekelwe kwimpembelelo yesikhumba, umphezulu we-workpiece ufudumala ngokukhawuleza kwiqondo lokushisa le-austenitizing (ukunyuka ukuya kwi-800 ~ 1000 ° C ngemizuzwana embalwa), ngelixa ingaphakathi le-workpiece lihlala liphantse lingatshisi. I-workpiece ipholiswe ngokutshiza ngamanzi, ukuphumeza ukuqina komphezulu.

4.I-Temper Brittleness

Ukuthomalalisa ubuqhophololo kwintsimbi ecinyiweyo

Ubushushu bentsimbi bubhekisa kwisenzeko apho ukuqina kwempembelelo yentsimbi ecinyiweyo kuncipha kakhulu xa ishushu kumaqondo athile obushushu.

Uhlobo lokuQala lwe-Brittleness Tempering

Uluhlu lobushushu: 250°C ukuya kuma-350°C.

Iimpawu: Ukuba intsimbi ecinyiweyo iyancitshiswa ngaphakathi kolu luhlu lweqondo lokushisa, kunokwenzeka kakhulu ukuphuhlisa olu hlobo lwe-brittleness epholileyo, engenako ukupheliswa.

Isisombululo: Kuphephe ukufudumeza intsimbi ecinyiweyo ngaphakathi kolu luhlu lobushushu.

Uhlobo lokuqala lwe-brittleness yokucaphuka lukwabizwa ngokuba yi-low-teering brittleness okanye ukucaphuka okungaguqukiyo.

Ⅵ.Ubushushu

I-1.I-Tempering yinkqubo yokugqibela yonyango yokushisa elandela ukucima.

Kutheni iintsimbi ezicinyiweyo zifuna ukufudumeza?

I-Microstructure Emva kokucima: Emva kokucima, i-microstructure yentsimbi iquka i-martensite kunye ne-austenite eseleyo. Zombini zizigaba ze-metastable kwaye ziya kutshintsha phantsi kweemeko ezithile.

Iipropati ze-Martensite:I-Martensite ibonakaliswe ngobulukhuni obuphezulu kodwa kunye nokuqina okuphezulu (ingakumbi kwi-carbon high-carbon-like-like martensite), engahlangabezani neemfuno zokusebenza kwizicelo ezininzi.

Iimpawu zeNguquko yeMartensitic:Utshintsho kwi-martensite lwenzeka ngokukhawuleza okukhulu. Emva kokucima, i-workpiece ineengcinezelo zangaphakathi ezishiyekileyo ezingakhokelela kwi-deformation okanye i-crack.

Isiphelo:I-workpiece ayinakusetyenziswa ngokuthe ngqo emva kokucima! Ukufudumala kuyimfuneko ukunciphisa uxinzelelo lwangaphakathi kunye nokuphucula ukuqina kwe-workpiece, okwenza ukuba ilungele ukusetyenziswa.

2.Umahluko phakathi koBulukhuni kunye noBukhuni obuQinisayo:

Ukuba lukhuni :

Ubunzima bubhekiselele kwisakhono sentsimbi ukufezekisa ubunzulu obuthile bokuqina (ubunzulu boluhlu olunzima) emva kokucima. Kuxhomekeke ekubunjweni kwentsimbi kunye nesakhiwo, ngokukodwa izinto zayo zokudibanisa kunye nohlobo lwentsimbi. Ukuqina ngumlinganiselo wendlela intsimbi enokuqina ngayo kulo lonke ubukhulu bayo ngexesha lokucima.

Ukuqina (Ukuqina koMmandla):

Ubunzima, okanye ukuqina kwamandla, kubhekisela kubunzima obukhulu obunokufumaneka kwintsimbi emva kokucima. Iphenjelelwa kakhulu ngumxholo wekhabhoni wentsimbi. Umxholo wekhabhoni ophezulu ngokubanzi ukhokelela kubunzima obuphezulu obunokubakho, kodwa oku kunokunqandwa yintsimbi ye-alloying elements kunye nokusebenza kwenkqubo yokucima.

3.Ukuqina kwentsimbi

√Umbono wokuqina

Ukuqina kubhekiselele kwisakhono sentsimbi ukufezekisa ubunzulu obuthile bokuqina kwe-martensitic emva kokucima ukusuka kwiqondo lobushushu le-austenitizing. Ngamagama alula, kukukwazi kwentsimbi ukwenza i-martensite ngexesha lokucima.

Umlinganiselo wokuqina

Ubungakanani bobunzima bubonakaliswa ubunzulu boluhlu olunzima olufunyenwe phantsi kweemeko ezichaziweyo emva kokucima.

Ubunzulu boMaleko Obulukhuni: Obu bubunzulu obusuka kumphezulu womsebenzi ukuya kummandla apho isakhiwo sisiqingatha semartensite.

Imidiya yokuCima eqhelekileyo:

•Amanzi

Iimpawu: Uqoqosho olunamandla okupholisa, kodwa lunezinga eliphezulu lokupholisa kufuphi nendawo yokubilisa, elinokukhokelela ekupholiseni okugqithisileyo.

Isicelo: Ngokuqhelekileyo isetyenziselwa iintsimbi zekhabhoni.

Amanzi eTyuwa: Isisombululo setyuwa okanye i-alkali emanzini, enomthamo ophezulu wokupholisa kumaqondo okushisa aphezulu xa kuthelekiswa namanzi, okwenza ukuba ilungele iintsimbi zekhabhoni.

•Oyile

Iimpawu: Ibonelela ngesantya sokupholisa esicothayo kumaqondo obushushu aphantsi (kufuphi nendawo yokubilisa), enciphisa ngokufanelekileyo i-deformation kunye nokuqhekeka, kodwa inamandla okupholisa asezantsi kumaqondo obushushu aphezulu.

Isicelo: Ifanelekile kwiintsimbi ze-alloy.

Iindidi: Kubandakanya ukucima ioli, ioyile yomatshini, kunye namafutha edizili.

Ixesha lokufudumeza

Ixesha lokufudumala libandakanya zombini izinga lokushisa (ixesha elithathiweyo ukufikelela kwiqondo lokushisa elifunekayo) kunye nexesha lokubamba (ixesha eligcinwe kwiqondo lokushisa elijoliswe kuyo).

Imigaqo yokumisela ixesha lokufudumeza: Qinisekisa ukuhanjiswa kwamaqondo obushushu afanayo kuyo yonke indawo yokusebenza, ngaphakathi nangaphandle.

Qinisekisa i-austenitization epheleleyo kunye nokuba i-austenite eyenziwe ifana kwaye ilungile.

Isiseko sokumisela ixesha lokufudumeza:Kuhlala kuqikelelwa kusetyenziswa iifomyula ezinobungqina okanye kugqitywe ngovavanyo.

Ukucima iMedia

Imiba emibini ePhambili:

a.Izinga lokupholisa: Izinga lokupholisa eliphezulu likhuthaza ukubunjwa kwe-martensite.

b.I-Residual Stress: Izinga lokupholisa eliphezulu linyusa uxinzelelo olushiyekileyo, olunokukhokelela ekuthandeni okukhulu kwe-deformation kunye nokuqhekeka kwi-workpiece.

Ⅶ.Ukulungelelanisa

1. Inkcazo yokuQinisa

I-normalizing yinkqubo yokunyanga ukushisa apho intsimbi ishushu kwiqondo lokushisa elingu-30 ° C ukuya kwi-50 ° C ngaphezu kweqondo lokushisa le-Ac3, eligcinwe kuloo bushushu, kwaye emva koko i-air-cooled ukuze ifumane i-microstructure kufuphi ne-equilibrium state. Xa kuthelekiswa ne-annealing, i-normalization inesantya sokupholisa ngokukhawuleza, okubangelwa isakhiwo se-pearlite esihle (P) kunye namandla aphezulu kunye nobunzima.

2. Injongo yokuQeqesha

Injongo ye-normalization ifana neyokukhupha.

3. Izicelo zokuQinisekisa

•Ukuphelisa i-samente yesibini yothungelwano.

•Ukusebenza njengonyango lokugqibela lobushushu kwiindawo ezineemfuno ezisezantsi.

•Yenza njengonyango lokulungiselela ubushushu kwintsimbi ephantsi kunye nephakathi ye-carbon structural steel ukuphucula ukunyanzeliswa.

4.Iintlobo ze-Anealing

Uhlobo lokuQala lokuHlola:

Injongo kunye noMsebenzi: Injongo ayiyikubangela ukuguqulwa kwesigaba kodwa ukuguqula insimbi ukusuka kwimeko engalinganiyo ukuya kwisimo esilinganayo.

Iintlobo:

• I-Diffusion Annealing: Ijolise ekwenzeni i-homogenize ukubunjwa ngokususa ulwahlulo.

•Recrystallization Annealing: Buyisela ductility ngokususa iziphumo umsebenzi nzima.

• I-Stress Relief Annealing: Ukunciphisa uxinzelelo lwangaphakathi ngaphandle kokuguqula i-microstructure.

Udidi lwesiBini lwe-Anealing:

Injongo kunye noMsebenzi: Ijolise ekutshintsheni i-microstructure kunye neepropati, ukufezekisa i-microstructure elawulwa yi-pearlite. Olu hlobo luqinisekisa kwakhona ukuba ukuhanjiswa kunye ne-morphology ye-pearlite, i-ferrite, kunye ne-carbides ihlangabezana neemfuno ezithile.

Iintlobo:

•I-Full Annealing: Ifudumeza intsimbi ngaphezu kobushushu be-Ac3 kwaye emva koko uyipholise kancinane ukuze ivelise ulwakhiwo olufanayo lweperilite.

•I-Anealing engaphelelanga: Ifudumeza intsimbi phakathi kwamaqondo obushushu e-Ac1 kunye ne-Ac3 ukuguqula ngokuyinxenye isakhiwo.

•I-Isothermal Annealing: Ifudumeza intsimbi ukuya ngaphezulu kwe-Ac3, ilandelwa kukupholisa ngokukhawuleza kwiqondo lobushushu le-isothermal kunye nokubamba ukufikelela kwisakhiwo esifunekayo.

• I-Spheroidizing Annealing: Ivelisa isakhiwo se-spheroidal carbide, ukuphucula ukucwangciswa kunye nokuqina.

Ⅷ.1.Inkcazo yoNyango loBubushushu

Ukunyangwa kobushushu kubhekiselele kwinkqubo apho isinyithi sifudunyezwa, sibanjwe kwiqondo elithile lobushushu, kwaye emva koko sipholile ngelixa sikwimeko eqinile ukuguqula isakhiwo sangaphakathi kunye ne-microstructure, ngaloo ndlela kufezekiswa iipropati ezifunwayo.

2.Iimpawu zoNyango loBushushu

Ukunyangwa kobushushu akutshintshi imilo ye-workpiece; endaweni yoko, iguqula isakhiwo sangaphakathi kunye ne-microstructure yentsimbi, leyo iguqula iipropati zentsimbi.

3.Injongo yoNyango loBubushushu

Injongo yonyango lobushushu kukuphucula i-mechanical or processing properties of steel (okanye workpieces), sebenzisa ngokupheleleyo amandla entsimbi, ukuphucula umgangatho we-workpiece, kunye nokwandisa ubomi bayo benkonzo.

4.Isiphelo esingundoqo

Ingaba iipropati zezinto eziphathekayo zingaphuculwa ngokunyanga ukushisa kuxhomekeke ngokubalulekileyo ukuba kukho utshintsho kwi-microstructure yayo kunye nesakhiwo ngexesha lokufudumala kunye nenkqubo yokupholisa.

Ixesha lokuposa: Aug-19-2024