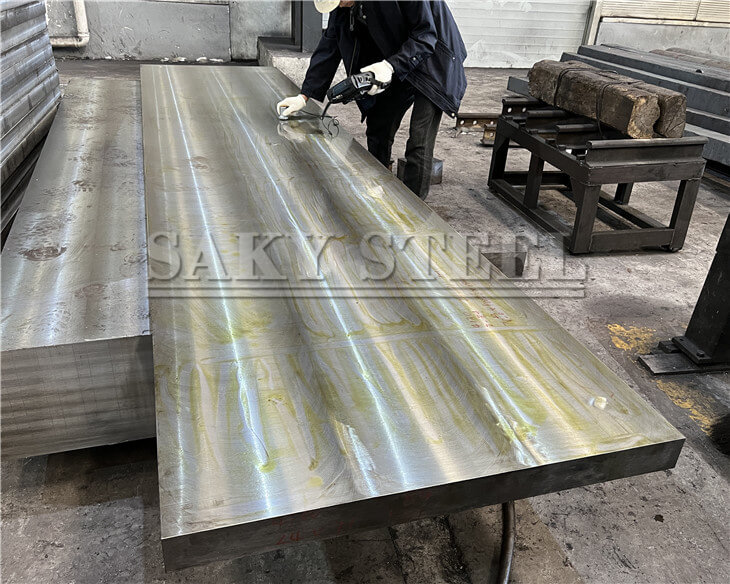

Ipleyiti yentsimbi ye-AISI 4130

Inkcazelo emfutshane:

I-AISI 4130 i-Steel Plate Supplier, inikezela ngolwazi oluneenkcukacha lwemveliso kuquka ukubunjwa, iipropati kunye nokusetyenziswa. Uthethwano lobuchwephesha kunye nenkonzo esemgangathweni ukukunika esona sisombululo silungileyo.

Ipleyiti yentsimbi ye-4130 yengxubevange:

I-AISI 4130 ipleyiti yensimbi yintsimbi ephantsi ye-alloy yodidi lwentsimbi ye-chromium-molybdenum. Inamandla aphezulu, ukuqina okugqwesileyo kunye ne-weldability kwaye isetyenziswa ngokubanzi kumashishini afana ne-aerospace, ukuveliswa kweemoto kunye nokwakhiwa. I-AISI 4130 ipleyiti yensimbi iye yaba yinto ekhethwayo kwiindawo ezininzi zoshishino ngenxa yamandla ayo abalaseleyo, ukuqina kunye nobuqili. Uluhlu lwayo olubanzi lwezicelo kunye neenkcukacha ezininzi zivumela ukuba ihlangabezane neemfuno ezahlukeneyo zobunjineli. Ukuba ufuna izinto ezikumgangatho ophezulu kunye nezithembekileyo zeplate yentsimbi, i-AISI 4130 ipleyiti yentsimbi lukhetho olufanelekileyo.

Iinkcukacha zePhepha leNsimbi le-4130:

| IBanga | 4130,4340 |

| Umgangatho | I-ASTM A829/A829M |

| Ububanzi & Ubude | 18" x 72" okanye 36" x 72" |

| Gqiba | Ipleyiti eqengqelekayo eshushu (HR), Ishiti eliqengqelekayo elibandayo (CR) |

| Mill Test Certificate | EN 10204 3.1 okanye EN 10204 3.2 |

| Izinto ezikrwada | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

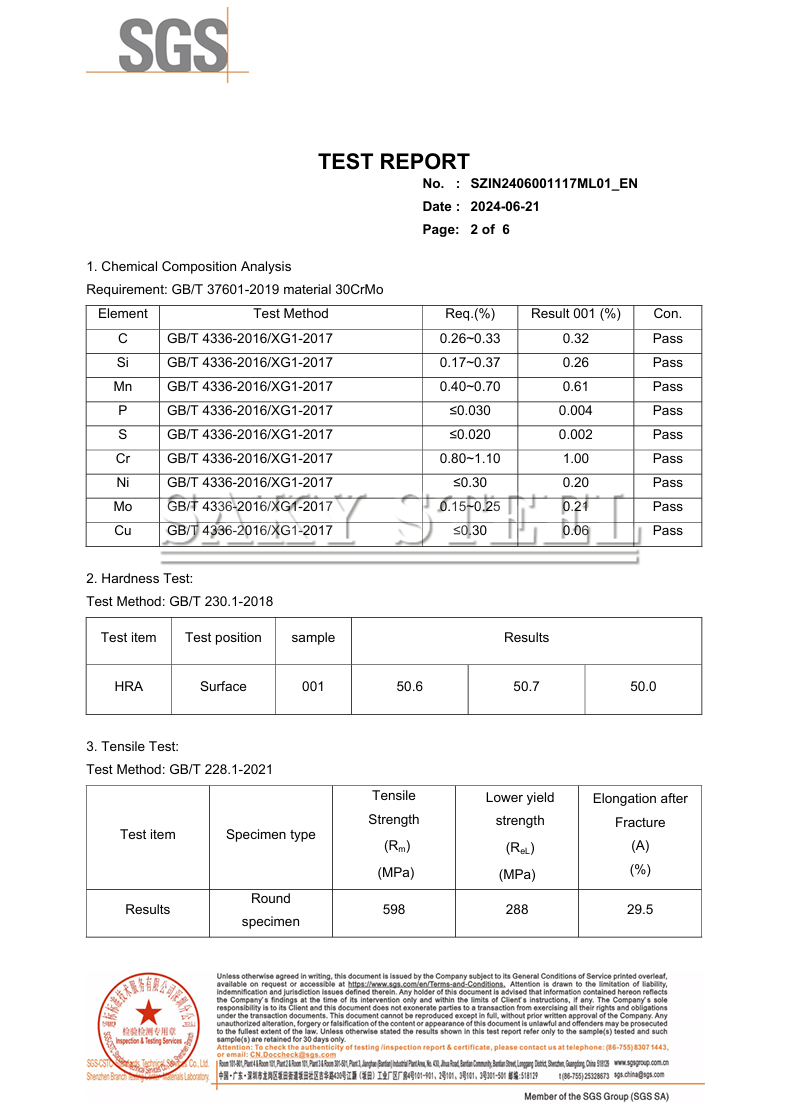

I-AISI 4130 yeNsimbi yePlati yoBume beMichiza:

| C | Si | Mn | P | S | Cr | Mo | Ni | Fe |

| 0.28-0.33 | 0.20-0.35 | 0.40-0.60 | 0.035 | 0.040 | 0.8-1.10 | 0.15-0.25 | 0.10 | Rem |

4130 iiPropathi zoomatshini bentsimbi:

| Amandla okuqina (MPa) | Unikeze Amandla | Elongation | Ukuqina kweBrinell (HBW) |

| 560 - 760 MPa | 460 MPa | 20% | 156 - 217 HB |

AISI 4130 Unyango lobushushu:

Iindlela eziqhelekileyo zokunyanga ubushushu be-AISI 4130 iipleyiti zentsimbi ziquka:

1. Ukudibanisa:

Ubushushu: 830°C (1525°F)

Inkqubo: Ukupholisa okucothayo kwiqondo lobushushu begumbi, ngokuqhelekileyo kwenziwa esithandweni.

2. Ukulungelelanisa:

Ubushushu: 900°C (1650°F)

Inkqubo: Ukupholisa umoya.

3. Ukucima kunye nokunciphisa:

Ukucima ubushushu: 860°C (1575°F)

Ubushushu bobushushu: 400 - 650 ° C (750 - 1200 ° F), kuxhomekeke kubulukhuni obufunwayo.

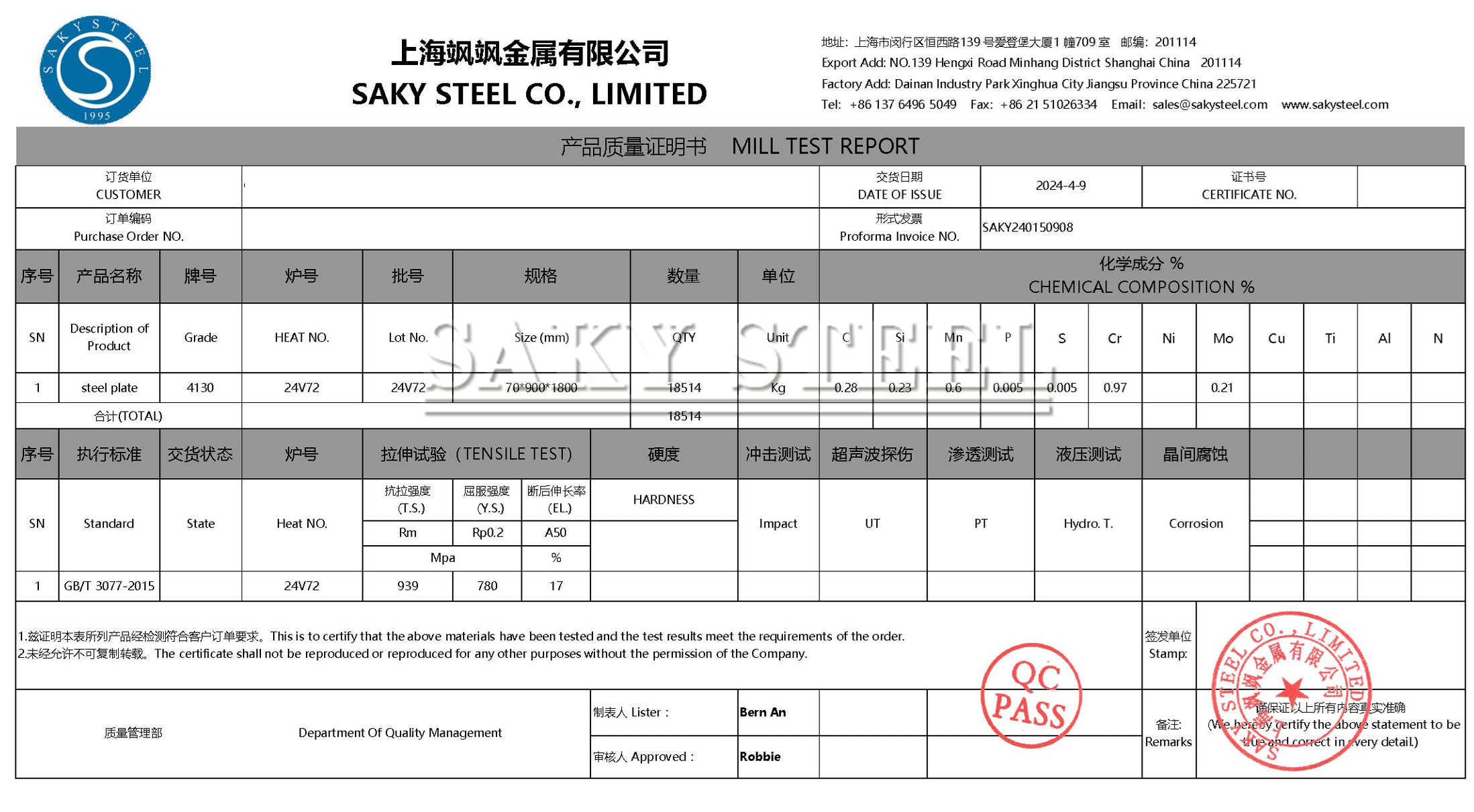

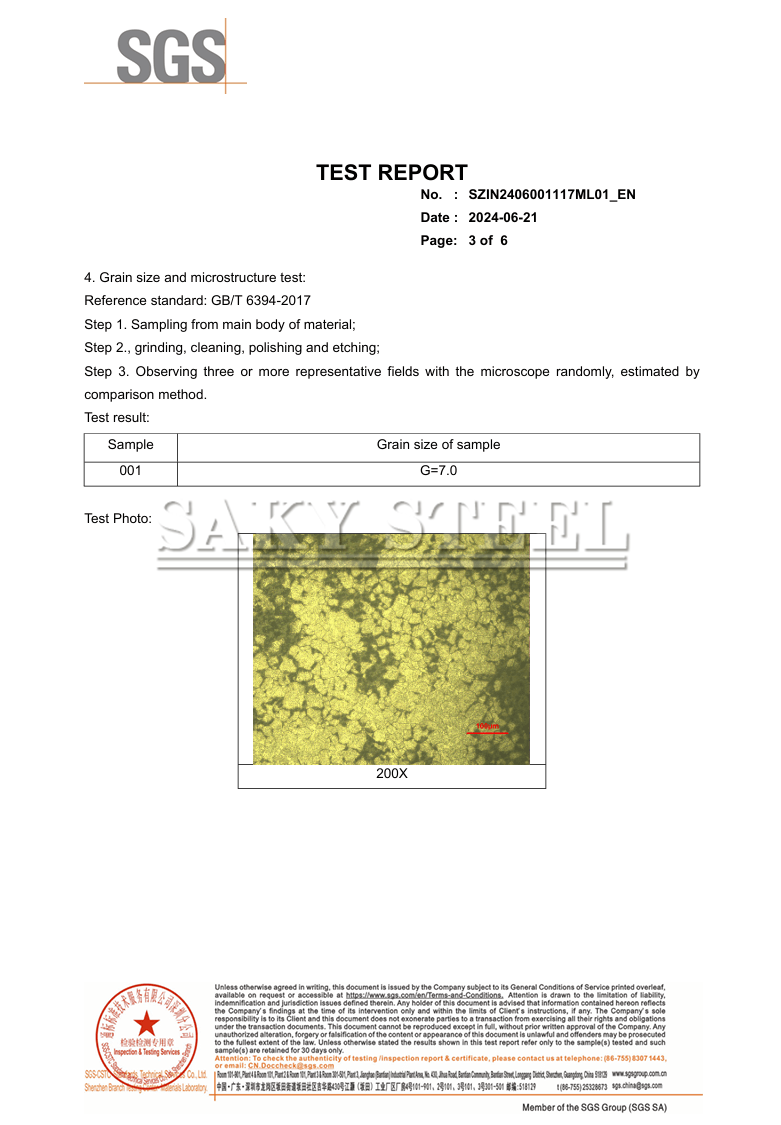

Isatifikethi se-4130 sepleyiti yentsimbi:

Ngokutsho kwe-GB / T 3077-2015 standard.

I-4130 ye-Steel Plate UT kunye noVavanyo loBulukhuni:

Uvavanyo lwe-UT

Uvavanyo lokuqina

Inqaku lePhepha le-AISI 4130:

1.Amandla aphezulu: akwazi ukumelana nemithwalo ephezulu kunye noxinzelelo.

2.Ukuqina okugqwesileyo: akulula ukuphuka phantsi koxinzelelo oluphezulu kunye nefuthe.

I-3.I-weldability enhle: kulula ukuyiqhuba kunye ne-weld, ifanelekile kwiinkqubo ezahlukeneyo zokuvelisa.

I-4.Ukuxhatshazwa kwe-Wear: igcina ukusebenza kakuhle kwindawo yokugqoka ephezulu.

I-5.I-Corrosion resistance: ixhathisa ukubola kwinqanaba elithile kwaye yandisa ubomi benkonzo.

Kutheni Khetha thina?

•Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

•Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhambisa umnyango ukuya emnyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

•Iimathiriyeli esizibonelelayo ziqinisekiswa ngokupheleleyo, ukusuka kwisiqinisekiso sovavanyo lwemathiriyeli ekrwada ukuya kwingxelo yokugqibela yomlinganiselo.(Iingxelo ziya kubonisa ngokwemfuneko)

•Siqinisekisa ukunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

•Nika ingxelo ye-SGS TUV.

•Sizinikele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

•Ukubonelela ngenkonzo yokumisa enye.

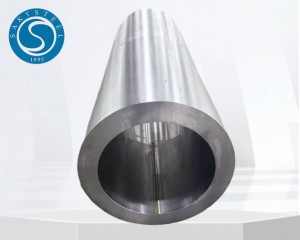

Iinkonzo zethu

1. Ukucima kunye nokufudumala

2.Ukunyanga ubushushu bevacuum

3.Isipili esimenyezeliswe phezulu

4.Precision-milled finish

4.CNC machining

5. Precision ukomba

6.Sika ube ngamacandelo amancinci

7.Ukuphumelela ukuchaneka okufana nokungunda

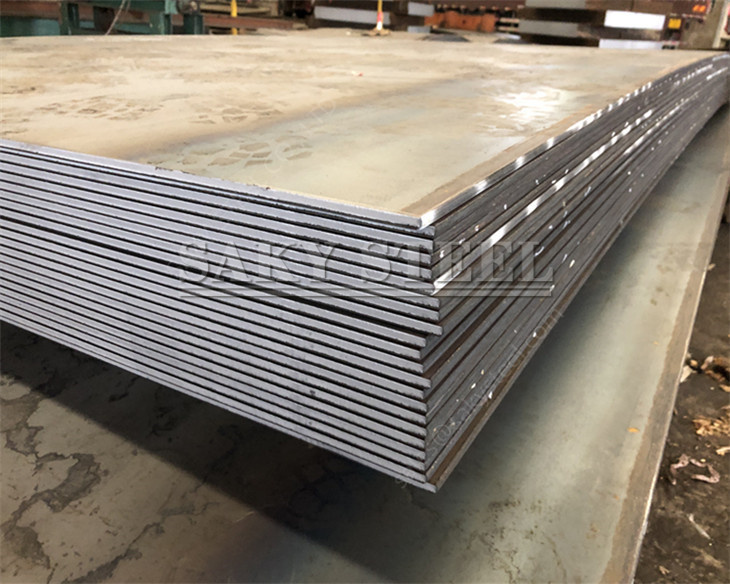

4130 Ukupakishwa kwePlayiti yeNsimbi yeAlloy:

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel's ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,