Tšepe e se nang Mokelikeli 17-4 PH Pipe Tube

Tlhaloso e Khutšoanyane:

Lekola khetho ea rona ea Stainless Steel 17-4 PH Pipe Tube - e fanang ka matla a holimo, ho hanyetsa kutu, le ts'ebetso. E loketse indasteri ea lifofane, tsa metsing le tsa lik'hemik'hale.

Teko ea Bokhopo ba Pipe ea Stainless Steel:

Stainless Steel 17-4 PH Pipe Tube ke thepa e matla haholo, e sa bolaeeng ke kutu e tsebahalang ka thepa ea eona e ntle haholo ea mochini. Joalo ka tšepe e sa tsitsang e thatafatsang pula, e fana ka motsoako oa matla a phahameng a tsitsitseng, ho tiea ho hotle, le ho hanyetsa ho hoholo ha oxidation le tikoloho e senyang. E loketse bakeng sa likopo sebakeng sa lifofane, tsa metsing, tsa lik'hemik'hale, le liindasteri tsa oli le khase, 17-4 PH pipe le tube li boloka matla a tsona esita le maemong a mocheso o phahameng le a khatello e phahameng, e leng se etsang hore e be khetho e fapaneng bakeng sa lik'hamphani tse hlokang indasteri.

Litlhaloso tsa 17-4 PH Stainless Steel Tube:

| Kereiti | 304,316,321,904L, joalo-joalo. |

| Standard | ASTM A/ASME SA213, A249, A269, A312, A358, A790 |

| Boholo | 1/8″NB HO 30″NB IN |

| Kemiso | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Mofuta | Seamless, Welded |

| Sebopeho | Rectangular, Round, Square, Capillary, jj |

| Bolelele | 5.8M, 6M,12M & Bolelele bo Hlokehang |

| QETA | Qetello e Beveled, Qetello e Setlehileng, E hatakeloa |

| Setifikeiti sa Tlhahlobo ea Mill | EN 10204 3.1 kapa EN 10204 3.2 |

17-4PH SS Pipe Chemical Sebopeho:

| Kereiti | C | Si | Mn | S | P | Cr | Ni | Cu |

| 17-4PH | 0.07 | 1.0 | 1.0 | 0.03 | 0.04 | 15.0-17.5 | 3.0-5.0 | 3.0-5.0 |

Thepa ea Mechini ea 17-4PH Peipi ea tšepe e sa hloekang:

| Kereiti | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Matla a Kotulo 0.2% Bopaki (MPa) min |

| 17-4PH | Psi - 170000 | 6 | Psi - 140,000 |

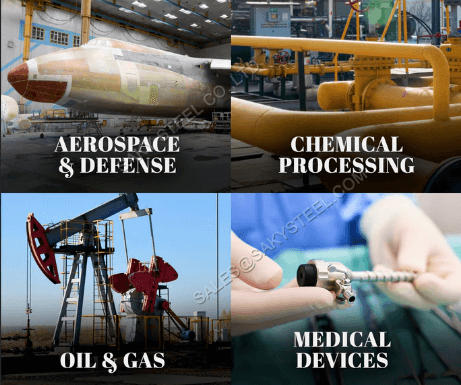

Maemo a kopo bakeng sa phala ea tšepe e sa hloekang 17-4 PH

1.Sepakapaka:E sebelisoa likarolong tsa meralo le likarolo tsa sefofane ka lebaka la tekanyo e phahameng ea matla ho boima ba 'mele.

2.Oli le Khase:E hiriloe lits'ebetsong tsa liphaephe bakeng sa khanyetso ea eona ho kutu maemong a thata.

3.Tlhahiso ea Lik'hemik'hale:E sebelisoa ka li-valve, lipompo le lisebelisoa tse ling moo ho tšoarellang le ho hanyetsa lik'hemik'hale ho leng bohlokoa.

4.Likopo tsa Marine:E loketse likarolo tse pepesehileng metsing a leoatle, kaha e mamella ho bola ha metsi a letsoai ka katleho.

5. Lisebelisoa tsa Bongaka:E sebelisoa ho lisebelisoa tsa ho buoa le li-implants ka lebaka la biocompatibility le matla a eona.

Melemo ea tšepe e sa hloekang 17-4 PH pipe

1.Matla a Phahameng:E fana ka matla a matle haholo le ho fana ka matla, e etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokang.

2.Corrosion Resistance:E fana ka khanyetso e ntle ho mefuta e fapaneng ea tikoloho e senyang, e matlafatsa nako e telele.

3.Mocheso o ka Phekoleha:E ka phekoloa mocheso ho finyella thepa e fapaneng ea mochine, e lumellang ho itlhophisa ho latela litlhoko tse itseng.

4. Mefuta e mengata:E loketse mefuta e mengata ea lisebelisoa, ho tloha sebakeng sa sefofane ho ea ho ts'ebetso ea lik'hemik'hale.

5.Mokhoa o motle:E entsoe habonolo le e cheselitsoeng, e lumellang hore ho be le mekhoa e metle ea tlhahiso.

Ke Hobane'ng ha U Re Khetha?

1.Ka boiphihlelo ba lilemo tse fetang 20, sehlopha sa rona sa litsebi se netefatsa boleng ba boleng bo holimo morerong o mong le o mong.

2.Re khomarela mekhoa e thata ea ho laola boleng ho netefatsa hore sehlahisoa se seng le se seng se finyella litekanyetso.

3.Re sebelisa theknoloji ea morao-rao le litharollo tse ncha ho fana ka lihlahisoa tse phahameng.

4.Re fana ka litheko tsa tlhōlisano ntle le ho sekisetsa boleng, ho netefatsa hore u fumana boleng bo botle ka ho fetisisa bakeng sa letsete la hau.

5.Re fana ka mefuta e fapaneng ea lits'ebeletso ho fihlela litlhoko tsohle tsa hau, ho tloha lipuisanong tsa pele ho isa phepelong ea ho qetela.

6.Boitlamo ba rona ho ts'ebetsong le mekhoa ea boitšoaro bo tiisa hore mekhoa ea rona e boloka tikoloho.

Netefaletso ea boleng:

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Teko e kholo

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Flaring Testing

8. Teko ea Jet ea Metsi

9. Penetrant Test

10. Tlhahlobo ea X-ray

11. Intergranular Corrosion Testing

12. Tlhahlobo ea phello

13. Eddy tlhahlobo ea hona joale

14. Tlhahlobo ea Hydrostatic

15. Metallography Teko ea Teko

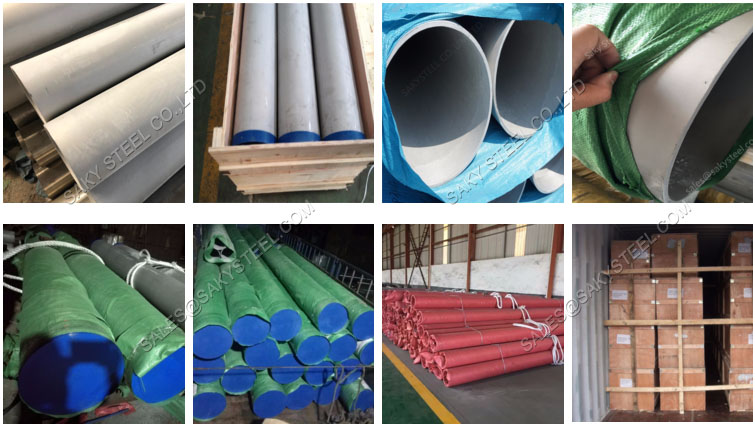

Sephutheloana sa Pipe ea Tšepe e sa senyeheng:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,