310 310S phala ea tšepe e sa tsitsang

Tlhaloso e Khutšoanyane:

310/310S lipeipi tsa tšepe tse se nang seamless, e fanang ka ho hanyetsa mocheso o babatsehang le ho hanyetsa kutu. E loketseng bakeng salisebelisoa tsa mocheso, libopi, le lisebelisoa tsa mocheso o phahameng.

310 310S phala ea tšepe e se nang seamless:

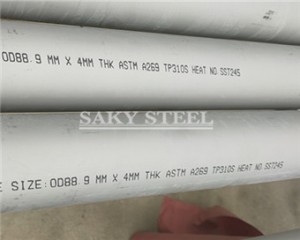

310/310S peipi e se nang seamless ea tšepe ke motsoako o sebetsang hantle, o sa chese mocheso o etselitsoeng lits'ebetso tsa mocheso o feteletseng. E entsoe ka tšepe e sa jeleng ea austenitic, e fana ka oxidation e ntle haholo le ho hanyetsa kutu ho fihla ho 1100 ° C (2012 ° F). Phapang ea khabone e tlase, 310S, e ntlafatsa ho cheseha le ho fokotsa pula ea carbide. E entsoe ho latela litekanyetso tsa ASTM A312 le ASME SA312, liphaephe tsena li sebelisoa haholo ho li-exchangers tsa mocheso, libopi, li-boilers le liindasteri tsa petrochemical. Ka boholo bo fapaneng ho tloha 1/8 "ho ea 24" (DN6-DN600) 'me e fumaneha ka SCH10 ho ea SCH160 botenya ba lerako, li tiisa matla a phahameng le ho tšoarella. Lisaese tse tloahelehileng le likhakanyo li fumaneha ka kopo.

Litlhaloso tsa Stainless Steel Seamless Tube:

| Liphaephe tse Seamless & Boholo ba Li-Tubes | 1 / 8" NB - 12" NB |

| Litlhaloso | ASTM A/ASME SA213, A249, A269, A312, A358, A790 |

| Kereiti | 304,310, 310S, 314, 316, 321,347, 904L, 2205, 2507 |

| Mekhoa | Ho chesa, ho huloa ka serame |

| Bolelele | 5.8M, 6M,12M & Bolelele bo Hlokehang |

| Kantle Diameter | 6.00 limilimithara OD ho fihla ho 914.4 limilimithara OD |

| Botenya | 0.6 limilimithara ho 12.7 limilimithara |

| Kemiso | SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS |

| Mefuta | Liphaephe tse Seamless |

| Sebopeho | Round, Square, Rectangle, Hydraulic, Honed Tubes |

| QETA | Qetello e Sephara, Qetello e Beveled, e hatakeloa |

| Setifikeiti sa Teko sa Mill | EN 10204 3.1 kapa EN 10204 3.2 |

310 /310S Liphaephe Tse Seamless Mephato e Tšoanang:

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | BS | GOST | HLOMPHO | EN |

| SS310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

SS 310 / 310S Seamless Pipes Sebopeho sa Lik'hemik'hale:

| Kereiti | C | Mn | Si | P | S | Cr | Mo | Ni |

| SS310 | 0.015 boholo | 2.0 max | 0.15 max | 0.020 max | 0.015 boholo | 24.00 - 26.00 | 0.10 max | 19.00 - 21.00 |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 boholo | 0.030 boholo | 24.00 - 26.00 | 0.75 boholo | 19.00 - 21.00 |

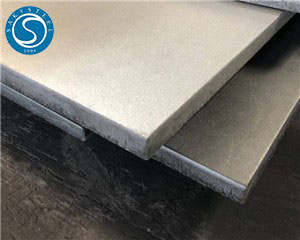

Thepa ea Mechini ea 310/310S Stainless Steel Pipe:

| Botenya | Melting Point | Matla a tšepe | Matla a Hlahisa (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 40% |

Lisebelisoa tsa 310 Stainless Steel Pipes:

• Petrochemical & Refinery - E sebelisoa ka mocheso oa mocheso le likarolo tsa sebōpi

• Limela tsa Matla - Li-tubes tsa boiler, li-superheater tubes

• Aerospace & Marine - Likarolo tsa sebopeho sa mocheso o phahameng

• Lijo le Meriana - Mechini ea lipeipi tse sa jeng

Ke Hobane'ng ha U Re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa hore re tla fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

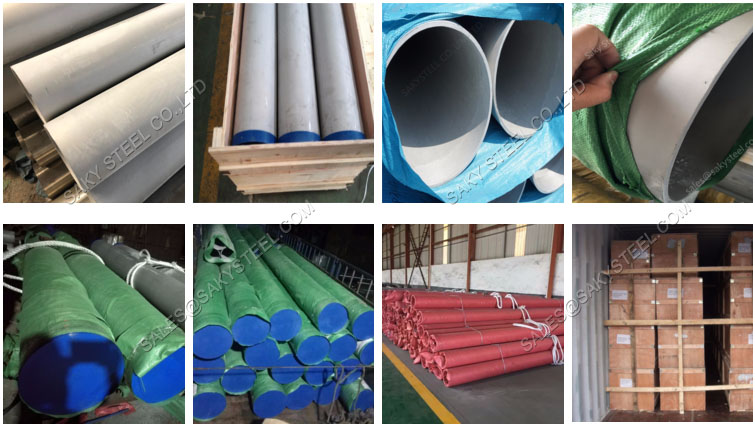

Sephutheloana sa Pipe ea Tšepe e sa senyeheng:

1. Ho paka ho bohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,