Ⅰ.Mohopolo oa motheo oa phekolo ea mocheso.

A. Khopolo ea motheo ea phekolo ea mocheso.

Lintlha tsa motheo le mesebetsi eaphekolo ea mocheso:

1.Ho futhumatsa

Sepheo ke ho fumana sebopeho se tšoanang le se setle sa austenite.

2.Ho tšoara

Sepheo ke ho netefatsa hore workpiece e futhumetse hantle le ho thibela decarburization le oxidation.

3.Ho pholisa

Sepheo ke ho fetola austenite hore e be microstructures e fapaneng.

Microstructures Ka mor'a Phekolo ea Mocheso

Nakong ea pholileng ka mor'a ho futhumatsa le ho tšoara, austenite e fetoha li-microstructures tse fapaneng ho itšetlehile ka sekhahla sa ho pholile. Li-microstructures tse fapaneng li bonts'a thepa e fapaneng.

B. Khopolo ea motheo ea phekolo ea mocheso.

Sehlopha se Thehiloe ho Mekhoa ea ho futhumatsa le ho futhumatsa, hammoho le Microstructure le Thepa ea tšepe

1. Kalafo e Tloaelehileng ea Mocheso (Kalafo ea Mocheso ka Kakaretso): Ho halefisa, Ho Annealing, Normalizing, Ho tima

2.Kalafo ea Mocheso oa Mocheso: Ho Tlosa Sefahleho, Ho Chesoa ha Mocheso oa Motlakase, Ho tima Lelakabe la Mocheso oa Lelakabe, Ho tima Motlakase oa Motlakase oa Motlakase.

3.Chemical Heat Treatment: Carburizing,Nitriding,Carbonitriding.

4.Litlhare Tse Ling Tsa Mocheso: Phekolo ea Mocheso e Laoloang, Phekolo ea Mocheso oa Vacuum, Phekolo ea Mocheso oa Deformation.

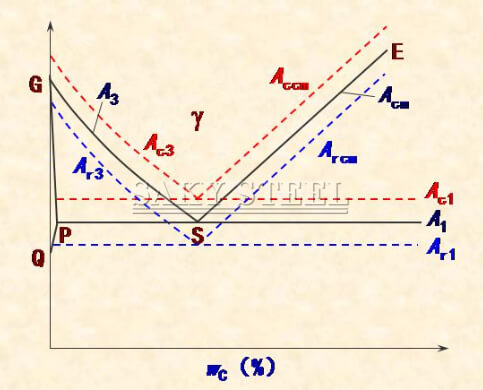

C.Critical Themperature of Steels

Mocheso oa bohlokoa oa phetoho ea tšepe ke motheo oa bohlokoa oa ho khetholla mekhoa ea ho futhumatsa, ho tšoara le ho pholile nakong ea phekolo ea mocheso. E khethoa ke setšoantšo sa mohato oa tšepe-khabone.

Qetello ea Bohlokoa:Mocheso oa sebele oa phetoho ea bohlokoa oa tšepe o lula o le ka morao ho mocheso oa phetoho o boima oa theory. Sena se bolela hore ho futhumala ho feteletseng hoa hlokahala nakong ea mocheso, 'me ho fokotseha hoa hlokahala nakong ea ho pholile.

Ⅱ.Annealing and Normalizing of Steel

1. Tlhaloso ea Annealing

Annealing e kenyelletsa ho futhumatsa tšepe mocheso ka holimo kapa ka tlase ho ntlha ea bohlokoa ea Ac₁ ho e tšoara mocheso oo, ebe o e pholile butle-butle, hangata ka har'a sebōpi, ho finyella mohaho o haufi le tekano.

2. Sepheo sa ho Anela

① Fetola boima bakeng sa Machining: Ho fihlela boima bo ka khonehang ka har'a HB170 ~ 230.

② Fokotsa Khatello ea Mesaletsa: E thibela ho senyeha kapa ho phatloha nakong ea mekhoa e latelang.

③ Hloekisa Sebopeho sa Lijo-thollo: E ntlafatsa sebopeho se senyenyane.

④Itokisetso bakeng sa Phekolo ea ho Qetela ea Mocheso: E fumana pearlite ea granular (spheroidized) bakeng sa ho tima le ho halefa ka mor'a moo.

3.Spheroidizing Annealing

Litlhaloso tsa Ts'ebetso: Mocheso oa mocheso o haufi le sebaka sa Ac₁.

Morero: Ho etsa spheroidize cementite kapa carbides ka tšepe, ho fella ka granular (spheroidized) pearlite.

Range e sebetsang: E sebelisoa bakeng sa litšepe tse nang le lipina tsa eutectoid le hypereutectoid.

4. Diffusing Annealing (Homogenizing Annealing)

Litlhaloso tsa Ts'ebetso: Mocheso oa mocheso o ka tlase hanyane ho mola oa solvus setšoantšong sa mohato.

Morero: Ho felisa karohano.

①Ho tlase-tšepe ea carbone nang le khabone e ka tlase ho 0.25%, ho tloaeleha ho khethoa ho feta ho annealing joalo ka kalafo ea mocheso oa boitokiso.

②Bakeng sa tšepe ea carbon e mahareng e nang le khabone e lipakeng tsa 0.25% le 0.50%, e ka sebelisoa e le kalafo ea mocheso kapa ea annealing.

③ Bakeng sa tšepe ea carbon e mahareng ho isa holimo e nang le khabone e lipakeng tsa 0.50% le 0.75%, ho khothaletsoa ho kenya anneal ka botlalo.

④Bakeng sa maemo a holimo-tšepe ea carbonka carbon content e kholo ho feta 0.75%, normalizing e qala ho sebelisoa ho felisa marang-rang Fe₃C, e lateloa ke spheroidizing annealing.

Ⅲ.Ho tima le ho Belafatsa Litšepe

A. Ho tima

1. Tlhaloso ea ho tima: Ho tima tšepe ho kopanyelletsa ho futhumatsa tšepe mochesong o itseng ka holimo ho Ac₃ kapa Ac₁ point, ho e tšoara ka mocheso oo, ebe o e pholisa ka lebelo le leholo ho feta tekanyo ea bohlokoa ea ho pholile ho etsa martensite.

2. Sepheo sa ho Tlosa: Sepheo se ka sehloohong ke ho fumana martensite (kapa ka linako tse ling bainite e tlaase) ho eketsa boima le ho apara ho hanyetsa ha tšepe. Ho tima ke e 'ngoe ea mekhoa ea bohlokoa ka ho fetisisa ea ho phekola mocheso bakeng sa tšepe.

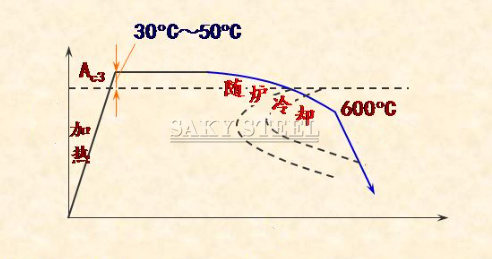

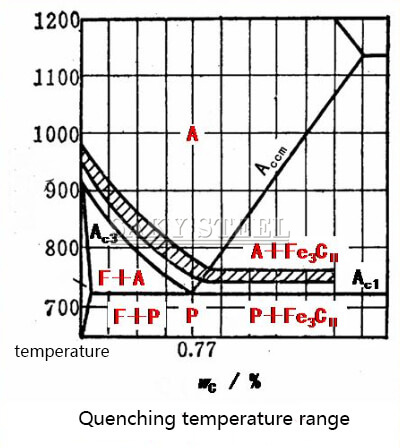

3.Ho Khetholla Lithempereichara tsa ho tima bakeng sa Mefuta e sa tšoaneng ea tšepe

Hypoeutectoid Steel: Ac₃ + 30°C ho ea ho 50°C

Eutectoid le Hypereutectoid Steel: Ac₁ + 30°C ho isa ho 50°C

Alloy Steel: 50 ° C ho 100 ° C ka holim'a mocheso o boima

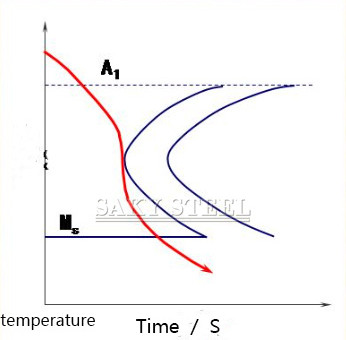

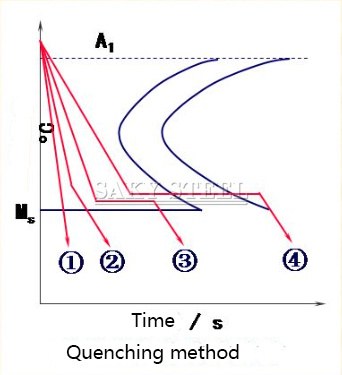

4. Litšobotsi tse Pholisang tsa Mokhoa o Loketseng oa ho Felisa:

Ho Pholisa butle Pele Mocheso oa "Nko": Ho fokotsa khatello ea mocheso ka mokhoa o lekaneng.

Matla a Ho Pholisa a Phahameng Haufi le Mocheso oa "Nko": Ho qoba ho thehoa ha meaho e seng martensitic.

Ho Pholisa butle Haufi le M₅ Ntlha: Ho fokotsa khatello ea maikutlo e bakoang ke phetoho ea martensitic.

5. Mekhoa ea ho tima le Litšobotsi tsa eona:

① Ho tima ho bonolo: Ho bonolo ho sebetsa ebile ho loketse lisebelisoa tse nyane, tse nang le sebopeho se bonolo. Sephetho sa microstructure ke martensite (M).

②Ho Tima Habeli: Ho rarahane haholoanyane le ho thata ho laola, ho sebelisoa bakeng sa tšepe e nang le sebōpeho se rarahaneng sa carbon high le lisebelisoa tse khōloanyane tsa alloy. Sephetho sa microstructure ke martensite (M).

③ Ho Qenngoa ho Senyehileng: Ts'ebetso e rarahaneng haholoanyane, e sebelisoang bakeng sa lisebelisoa tsa tšepe tse kholo, tse raraaneng. Sephetho sa microstructure ke martensite (M).

④Isothermal Quenching: E sebelisoa bakeng sa lisebelisoa tse nyane, tse rarahaneng tse nang le litlhoko tse phahameng. The microstructure e hlahisoang ke bainite e tlaase (B).

6.Lintho Tse Amang Bothata

Boemo ba ho thatafala ho itšetlehile ka botsitso ba supercooled austenite ka tšepe. Ho phahama ha botsitso ba supercooled austenite, ho molemo ho thatafala, 'me ka tsela e fapaneng.

Lintlha tse susumetsang botsitso ba Supercooled Austenite:

Boemo ba C-Curve: Haeba C-curve e fetohela ka ho le letona, sekhahla sa ho pholisa sa bohlokoa bakeng sa ho tima sea fokotseha, ho ntlafatsa ho thatafala.

Qetello ea Bohlokoa:

Ntho leha e le efe e fetolang C-curve ho ea ka ho le letona e eketsa ho tiea ha tšepe.

Ntlha e ka Sehloohong:

Sebopeho sa Lik'hemik'hale: Ntle le cobalt (Co), likarolo tsohle tsa alloying tse qhibilihisitsoeng ka austenite li eketsa ho thatafala.

Ha carbon content e le haufi le sebopeho sa eutectoid ka carbon steel, C-curve e fetela ka ho le letona, 'me e phahame ho thatafala.

7.Boikemisetso le boemedi ba ho thatafala

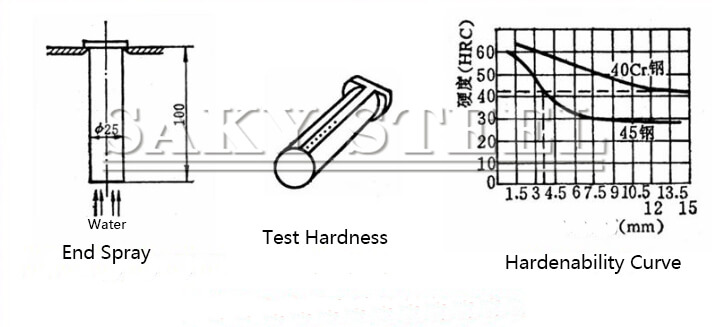

①Teko ea Qetello ea Bothata: Ho thatafala ho lekanyetsoa ho sebelisoa mokhoa oa tlhahlobo ea ho qetela.

②Critical Quench Diameter Method: The key quench Diameter (D₀) e emela bophara bo boholo ba tšepe bo ka thatafalloang ka ho feletseng ka mokhoa o itseng oa ho tima.

B. Ho halefa

1. Tlhaloso ea Tempering

Ho futhumatsa ke mokhoa oa ho phekola mocheso moo tšepe e tingoeng e futhumatsang mocheso o ka tlase ho ntlha ea A₁, e tšoaroang mocheso oo, ebe e pholile ho ea mocheso oa kamore.

2. Sepheo sa ho halefisa

Fokotsa kapa U Felise Khatello ea Mesaletsa: E thibela deformation kapa ho phatloha ha workpiece.

Fokotsa kapa u Felise Residual Austenite: E tsitsisa litekanyo tsa mosebetsi.

Felisa Brittleness of Quenched Steel: E lokisa microstructure le thepa ho fihlela litlhoko tsa workpiece.

Keletso ea Bohlokoa: Tšepe e lokela ho halefa hang ka mor'a ho tima.

3.Mekhoa ea ho futhumatsa

1.Ho halefa ho tlase

Morero: Ho fokotsa khatello ea maikutlo, ho ntlafatsa ho tiea ha mosebetsi, le ho fihlela boima bo phahameng le ho hanyetsa ho roala.

Mocheso: 150°C ~ 250°C.

Tshebetso: Ho thatafala: HRC 58 ~ 64. Boima bo phahameng le ho hanyetsa ho apara.

Lisebelisoa: Lisebelisoa, hlobo, li-bearings, likarolo tsa carburized, le likarolo tse thata-thata.

2.Ho halefa haholo

Morero: Ho fihlela boima bo phahameng hammoho le matla a lekaneng le boima.

Mocheso: 500°C ~ 600°C.

Tshebetso: Ho thatafala: HRC 25 ~ 35. Lintho tse ntle ka kakaretso tsa mochine.

Lisebelisoa: Shafts, likere, lithupa tse hokahanyang, joalo-joalo.

Ho Hloekisa Mocheso

Tlhaloso: Ho tima ho lateloang ke mocheso o phahameng oa mocheso ho bitsoa ho hloekisoa ha mocheso, kapa ho foka feela. Ts'epe e tšoaroang ke ts'ebetso ena e na le ts'ebetso e ntle ka kakaretso mme e sebelisoa haholo.

Ⅳ.Kalafo ea Mocheso oa Bokaholimo oa Tšepe

A. Ho Timetsoa ha Litšepe ka Bokaholimo

1. Tlhaloso ea Ho thatafala ha Sebaka

Ho thatafatsa holim'a metsi ke mokhoa oa ho phekola mocheso o etselitsoeng ho matlafatsa bokaholimo ba karolo ea mosebetsi ka ho e futhumatsa ka potlako ho fetola bokaholimo hore e be austenite ebe o e pholisa kapele. Ts'ebetso ena e etsoa ntle le ho fetola sebopeho sa lik'hemik'hale tsa tšepe kapa sebopeho sa mantlha sa thepa.

2. Lisebelisoa tse Sebelisitsoeng Bakeng sa ho thatafatsa holim'a sefahleho le Sebopeho sa ka mor'a ho thatafala

Lintho Tse Sebelisitsoeng Bakeng sa Ho thatafatsa Bokaholimo

Lisebelisoa tse Tloaelehileng: Tšepe ea khabone e mahareng le tšepe e kopaneng ea khabone.

Phekolo ea Pele:Tsela e Tloaelehileng: Tempering. Haeba thepa ea mantlha e se ea bohlokoa, ho ka sebelisoa normalizing ho fapana le hoo.

Sebopeho sa kamora ho thatafala

Sebopeho sa Bokaholimo: Lera la bokaholimo hangata le etsa sebopeho se thata joalo ka martensite kapa bainite, e fanang ka boima bo phahameng le ho hanyetsa ho roala.

Sebopeho sa Core: Moko oa tšepe ka kakaretso o boloka sebopeho sa oona sa pele, joalo ka perela kapa boemo bo halefileng, ho itšetlehile ka ts'ebetso ea pele ho phekolo le thepa ea thepa ea motheo. Sena se tiisa hore motheo o boloka boima bo botle le matla.

B. Litšobotsi tsa ho thatafatsa holim'a induction

1.Mocheso o Phahameng oa Mocheso le Mocheso o Potlakileng oa Mocheso: Ho thatafatsa holim'a induction ka tloaelo ho kenyelletsa mocheso o phahameng oa mocheso le mocheso o potlakileng oa ho futhumatsa, o lumellang ho futhumala kapele ka nako e khutšoanyane.

2.Sebopeho se setle sa Grain ea Austenite ka Lera la Bokaholimo: Nakong ea ho futhumatsa ka potlako le ts'ebetso e latelang ea ho tima, sekhahla sa bokaholimo se etsa lithollo tse ntle tsa austenite. Kamora ho tima, bokaholimo bo na le martensite e ntle, 'me hangata boima ba 2-3 HRC bo phahame ho feta ho tima ho tloaelehileng.

3.Boleng bo Botle ba Bokaholimo: Ka lebaka la nako e khuts'oane ea ho futhumatsa, sebaka sa mosebetsi ha se khone ho ba le oxidation le decarburization, 'me deformation e bakoang ke ho tima e fokotsehile, e netefatsa boleng bo botle ba bokaholimo.

4.Matla a Mokhathala a Phahameng: Phetoho ea karolo ea martensitic karolong e ka holimo e hlahisa khatello ea maikutlo, e leng ho eketsang matla a mokhathala oa mosebetsi.

5.Tlhahiso e Phahameng ea Phatlalatso: Ho thatafatsa holim'a induction ho loketse bakeng sa tlhahiso ea bongata, ho fana ka ts'ebetso e phahameng ea ts'ebetso.

C. Sehlopha sa phekolo ea mocheso oa lik'hemik'hale

Carburizing, Carburizing, Carburizing, Chromizing, Siliconezing, Siliconizing, Siliconizing, Carbonitriding, Borocarburizing

D.Gas Carburizing

Gas Carburizing ke ts'ebetso eo ho eona sesebedisoa se beoang ka seboping se tiisitsoeng sa khase ebe se futhumatsoa ho mocheso o fetolang tšepe hore e be austenite. Ebe, "carburizing agent" e rotheloa ka seboping, kapa sepakapaka sa "carburizing" se hlahisoa ka kotloloho, se lumellang liathomo tsa carbon hore li kenelle karolong e ka holimo ea sebaka sa mosebetsi. Ts'ebetso ena e eketsa litaba tsa khabone (wc%) sebakeng sa mosebetsi.

√Carburizing Agents:

•Ligase tse nang le carbon e ngata: Tse kang mashala, liquefied petroleum gas (LPG), joalo-joalo.

•Mokelikeli oa Metsi: Joalo ka parafine, methanol, benzene, joalo-joalo.

√Carburizing Process Parameters:

•Mocheso oa ho boloka koloi: 920~950°C.

• Nako ea ho Bua: E ipapisitse le botebo bo lakatsehang ba lera la carburized le mocheso oa carburizing.

Kalafo ea E.Heat Ka mor'a Carburizing

Litšepe li tlameha ho fumana kalafo ea mocheso ka mor'a carburizing.

Mokhoa oa Phekolo ea Mocheso ka mor'a Carburizing:

√Ho tima + Mocheso o Tlase

1.Ho tima ka ho toba ka mor'a hore ho be le Pholiso ea Pele + Ho Fokotsa Mocheso o Motle: The workpiece e pholile esale pele ho tloha mocheso oa carburizing ho ea ka holim'a mocheso oa Ar₁ oa mantlha ebe oa tima hang-hang, o lateloa ke mocheso o tlase oa mocheso ho 160 ~ 180 ° C.

2. Single Quenching Ka mor'a Pele ho Pholiso + Mocheso o Tlaase: Ka mor'a carburizing, workpiece butle-butle e pholile mocheso oa kamore, ebe e futhumatsoa hape bakeng sa ho tima le mocheso o tlaase.

3. Ho tima ka makhetlo a mabeli ka mor'a ho futhumatsa pele ho mocheso + o tlase oa mocheso: Ka mor'a ho pholile ha koloi le ho phomola butle, mosebetsi oa ho sebetsa o feta mekhahlelo e 'meli ea ho futhumatsa le ho tima, e lateloa ke mocheso o tlase oa mocheso.

Ⅴ.Kalafo ea Mocheso oa Mocheso oa Litšepe

1.Tlhaloso ea Phekolo ea Mocheso oa Lik'hemik'hale

Kalafo ea mocheso oa lik'hemik'hale ke mokhoa oa ho phekola mocheso oo ho oona ho behoang tšepe ea tšepe sebakeng se itseng se sebetsang, se futhumetse, 'me se tšoaretsoe mocheso, se lumella liathomo tse sebetsang tse bohareng hore li atamele holim'a sebaka sa mosebetsi. Sena se fetola sebopeho sa lik'hemik'hale le sebopeho sa microstructure sa bokaholimo ba mosebetsi, ka hona se fetola thepa ea sona.

2.Mokhoa oa Motheo oa Phekolo ea Mocheso oa Lik'hemik'hale

Ho senyeha: Nakong ea mocheso, sebaka se sebetsang se senyeha, se lokolla liathomo tse sebetsang.

Ho monya: Liathomo tse sebetsang li khangoa ke bokaholimo ba tšepe 'me li qhibiliha ka har'a tharollo e tiileng ea tšepe.

Diffusion: Liathomo tse sebetsang tse monyetsoeng le ho qhibiliha ka holim'a tšepe li fallela ka hare.

Mefuta ea Induction Surface Hardening

a.High-Frequency Induction Heating

Maqhubu a Hona Joale: 250 ~ 300 kHz.

Botebo ba Lera le thata: 0.5 ~ 2.0 mm.

Lisebelisoa: Li-module tse mahareng le tse nyane le lishafi tse nyane ho isa ho tse mahareng.

b.Medium-Frequency Induction Heating

Maqhubu a Hona Joale: 2500 ~ 8000 kHz.

Botebo ba Lera le thatafalitsoeng: 2 ~ 10 mm.

Lisebelisoa: Li-shaft tse kholoanyane le likere tse kholo ho isa ho tse mahareng.

c.Matla-Frequency Induction Heating

Maqhubu a Hona Joale: 50 Hz.

Botebo ba Lera le thata: 10 ~ 15 mm.

Lisebelisoa: Lisebelisoa tse hlokang lera le thata haholo le thata.

3. Induction Surface Hardening

Molao-motheo oa Motheo oa ho Hafatsa Sefahleho sa Induction

Letlalo:

Ha ho feto-fetoha ha hona joale ka har'a coil ea induction ho etsa hore ho be le hona joale holim'a sebaka sa mosebetsi, boholo ba motlakase o ts'oaretsoeng o tsepamisitsoe haufi le bokaholimo, athe ha ho na hona joale o fetang ka hare ho setsi sa mosebetsi. Ketsahalo ena e tsejoa e le phello ea letlalo.

Molao-motheo oa ho thatafatsa ka holim'a induction:

Ho itšetlehile ka phello ea letlalo, bokaholimo ba workpiece bo futhumala ka potlako ho mocheso oa austenitizing (ho nyolohela ho 800 ~ 1000 ° C ka metsotsoana e seng mekae), ha karolo e ka hare ea workpiece e ntse e batla e sa chesoa. Joale workpiece e pholile ka ho fafatsa metsi, ho finyella ho thatafala ha holim'a metsi.

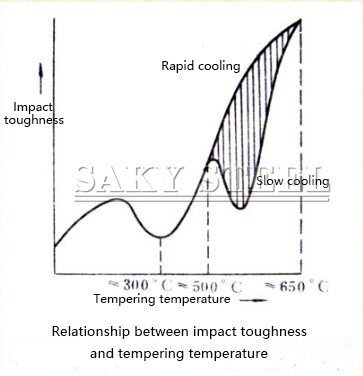

4.Mohale oa Brittleness

Brittleness e Felisang ka Tšepe e Tingoeng

Tempering brittleness e bolela ketsahalo eo ho eona matla a ts'ebetso ea tšepe e tingoeng a fokotsehang haholo ha a halefile ka mocheso o itseng.

Mofuta oa Pele oa Tempering Brittleness

Sebaka sa Mocheso: 250°C ho isa ho 350°C.

Litšobotsi: Haeba tšepe e tingoeng e halefile ka har'a mofuta ona oa mocheso, ho na le monyetla o moholo oa ho hlahisa mofuta ona oa brittleness, o ke keng oa felisoa.

Tharollo: Qoba ho futhumatsa tšepe e tingoeng ka har'a mofuta ona oa mocheso.

Mofuta oa pele oa brittleness ea ho halefisa o boetse o tsejoa e le brittleness ea mocheso o tlase kapa brittleness e ke keng ea fetoloa.

Ⅵ.Ho halefa

1.Tempering ke mokhoa oa ho qetela oa phekolo ea mocheso o latelang ho tima.

Ke Hobane'ng ha Litšepe Tse Chesitsoeng li Hloka ho Futhumatsoa?

Microstructure After Quenching: Kamora ho tima, microstructure ea tšepe hangata e na le martensite le residual austenite. Ka bobeli ke mekhahlelo e metastable 'me e tla fetoha tlas'a maemo a itseng.

Thepa ea Martensite:Martensite e tšoauoa ka ho thatafala ho hoholo empa hape le brittleness e phahameng (haholo-holo ka har'a carbon nale-like martensite), e sa fihlelle litlhoko tsa ts'ebetso bakeng sa lits'ebetso tse ngata.

Litšobotsi tsa Phetoho ea Martensitic: Phetoho ho martensite e etsahala ka potlako haholo. Ka mor'a ho tima, workpiece e na le likhatello tse setseng tsa ka hare tse ka lebisang ho deformation kapa ho phunyeha.

Qetello: Sesebelisoa sa mosebetsi se ke ke sa sebelisoa ka kotloloho kamora ho tima! Ho tsitsa hoa hlokahala ho fokotsa khatello ea kelello ka hare le ho ntlafatsa ho tiea ha workpiece, ho etsa hore e loketse ho sebelisoa.

2.Phapang lipakeng tsa ho thatafala le ho thatafatsa bokhoni:

Ho thatafala :

Hardenability e bolela bokhoni ba tšepe ho finyella botebo bo itseng ba ho thatafala (botebo ba lera le thata) ka mor'a ho tima. E itšetlehile ka sebopeho le sebopeho sa tšepe, haholo-holo likarolo tsa eona tsa motsoako le mofuta oa tšepe. Ho thatafala ke tekanyo ea hore na tšepe e ka thatafala hakae ho pholletsa le botenya ba eona nakong ea ts'ebetso ea ho tima.

Ho thatafala (Bokhoni bo thatafatsang):

Ho thata, kapa ho thatafatsa bokhoni, ho bolela boima bo boholo bo ka finyelloang ka tšepe ka mor'a ho tima. E susumetsoa haholo ke carbon content ea tšepe. Likahare tsa khabone e phahameng hangata li lebisa ho thatafalang ho phahameng, empa sena se ka fokotsoa ke likarolo tsa tšepe tsa alloying le katleho ea ts'ebetso ea ho tima.

3.Hardenability of Steel

√Mohopolo oa ho thatafala

Hardenability e bolela bokhoni ba tšepe ho finyella botebo bo itseng ba ho thatafala ha martensitic ka mor'a ho tima mocheso oa austenitizing. Ka mantsoe a bonolo, ke bokhoni ba tšepe ho theha martensite nakong ea ho tima.

Tekanyo ea ho thatafala

Boholo ba ho thatafala ho bontšoa ke botebo ba lera le thata le fumanoang tlas'a maemo a boletsoeng ka mor'a ho tima.

Botebo ba Lera le thata: Bona ke botebo ho tloha holim'a sebaka sa mosebetsi ho ea sebakeng seo sebopeho se leng halofo ea martensite.

Mecha e Tloaelehileng ea ho Tlosa:

•Metsi

Litšobotsi: E na le moruo o nang le matla a ho pholisa, empa e na le sekhahla se phahameng sa ho pholisa haufi le sebaka se belang, se ka lebisang ho pholiso e feteletseng.

Kopo: Hangata e sebelisoa bakeng sa litšepe tsa carbon.

Metsi a Letsoai: Tharollo ea letsoai kapa alkali ka metsing, e nang le matla a holimo a ho pholisa mocheso o phahameng ha o bapisoa le metsi, e leng se etsang hore e tšoanelehe bakeng sa litšepe tsa carbon.

•Oli

Litšobotsi: E fana ka sekhahla sa ho pholisa butle mochesong o tlase (haufi le sebaka se belang), e leng ho fokotsang ka nepo tšekamelo ea ho holofala le ho peperana, empa e na le bokhoni bo tlase ba ho pholisa mochesong o phahameng.

Kopo: E loketse litšepe tsa alloy.

Mefuta: E kenyelletsa oli ea ho tima, oli ea mochini, le mafura a disele.

Ho futhumatsa Nako

Nako ea ho futhumatsa e na le lebelo la ho futhumatsa ka bobeli (nako e nkiloeng ho fihlela mocheso o lakatsehang) le nako ea ho tšoara (nako e bolokiloeng mocheso o lebisitsoeng).

Melao-motheo ea ho Khetholla Nako ea ho futhumatsa: Netefatsa kabo ea mocheso o ts'oanang ho pholletsa le sebaka sa mosebetsi, kahare le kantle.

Etsa bonnete ba hore austenitization e feletseng le hore austenite e entsoeng e lekana ebile e ntle.

Motheo oa ho Fumana Nako ea ho Futhumala: Hangata e hakanngoa ho sebelisoa liforomo tse matla kapa ho khethoa ka liteko.

Ho tima Media

Lintlha tse peli tsa bohlokoa:

a.Sekhahla sa Pholiso: Sekhahla se phahameng sa ho pholisa se khothalletsa ho thehoa ha martensite.

b.Residual Stress: Sekhahla se phahameng sa ho pholile se eketsa khatello ea kelello e setseng, e ka lebisang ho tšekamelo e kholo ea ho senyeha le ho phunyeha ha mosebetsi.

Ⅶ.E tloaelehileng

1. Tlhaloso ea Normalizing

Ho tloaeleha ke mokhoa oa ho phekola mocheso oo tšepe e futhumatsang mocheso oa 30 ° C ho ea ho 50 ° C ka holimo ho mocheso oa Ac3, o tšoaretsoeng mocheso oo, ebe o pholile moea ho fumana microstructure e haufi le boemo ba tekano. Ha ho bapisoa le annealing, normalizing e na le lebelo la ho pholisa ka potlako, e leng se hlahisang sebopeho se setle sa pearlite (P) le matla a phahameng le ho thatafala.

2. Sepheo sa ho tloaeleha

Sepheo sa ho tloaeleha se tšoana le sa annealing.

3. Likopo tsa Normalizing

•Felisa samente ea bobeli ea marang-rang.

• Sebeletsa e le phekolo ea ho qetela ea mocheso bakeng sa likarolo tse nang le litlhoko tse tlaase.

• Sebetsa e le pheko ea ho lokisetsa mocheso bakeng sa tšepe e tlaase le e bohareng ea carbon ho ntlafatsa machinability.

4.Mefuta ea Anealing

Mofuta oa pele oa ho ikoetlisa:

Sepheo le Mosebetsi: Sepheo ha se ho susumetsa phetoho ea mekhahlelo empa ke ho fetola tšepe ho tloha boemong bo sa tsitsang ho ea boemong bo leka-lekaneng.

Mefuta:

• Diffusion Annealing: E ikemiselitse ho etsa homogenize sebopeho ka ho felisa karohano.

• Recrystallization Annealing: Ho tsosolosa ductility ka ho felisa liphello tsa ho thatafatsa mosebetsi.

•Stress Relief Annealing: Ho fokotsa khatello ea kelello ka hare ntle le ho fetola microstructure.

Mofuta oa bobeli oa ho ikoetlisa:

Sepheo le Mosebetsi: Sepheo sa ho fetola microstructure le thepa, ho finyella microstructure e laoloang ke pearlite. Mofuta ona o boetse o netefatsa hore kabo le morphology ea pearlite, ferrite, le carbides li fihlela litlhoko tse ikhethang.

Mefuta:

• Full Annealing: E futhumatsa tšepe ka holim'a mocheso oa Ac3 ebe oa e pholisa butle-butle ho hlahisa sebopeho se tšoanang sa perela.

•Anealing e sa Feleng: E futhumatsa tšepe pakeng tsa mocheso oa Ac1 le Ac3 ho fetola sebopeho.

• Isothermal Annealing: E futhumatsa tšepe ho ea ka holimo ho Ac3, e lateloa ke ho pholile ka potlako ho mocheso oa isothermal le ho tšoara ho finyella sebopeho se lakatsehang.

•Spheroidizing Annealing: E hlahisa sebopeho sa spheroidal carbide, ho ntlafatsa machinability le ho tiea.

Ⅷ.1.Tlhaloso ea Phekolo ea Mocheso

Phekolo ea mocheso e bua ka mokhoa oo tšepe e futhumatsang ka eona, e tšoaroang ka mocheso o itseng, ebe e pholile ha e ntse e le boemong bo tiileng ho fetola sebopeho sa eona sa ka hare le microstructure, kahoo e finyella thepa e lakatsehang.

2.Litšobotsi tsa Phekolo ea Mocheso

Phekolo ea mocheso ha e fetole sebopeho sa workpiece; ho e-na le hoo, e fetola sebopeho sa ka hare le microstructure ea tšepe, e leng eona e fetolang thepa ea tšepe.

3.Morero oa Phekolo ea Mocheso

Sepheo sa phekolo ea mocheso ke ho ntlafatsa thepa ea mochine kapa ea ho sebetsa ea tšepe (kapa li-workpieces), ho sebelisa ka botlalo bokhoni ba tšepe, ho ntlafatsa boleng ba mosebetsi, le ho lelefatsa bophelo ba eona ba tšebeletso.

4.Sephetho sa Bohlokoa

Hore na thepa ea thepa e ka ntlafatsoa ka ho phekola mocheso ho itšetlehile haholo ka hore na ho na le liphetoho ho microstructure ea eona le sebopeho nakong ea ho futhumatsa le ho pholisa.

Nako ea poso: Aug-19-2024