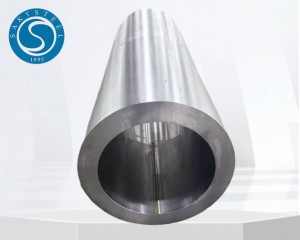

DIN 1.2311 P20 Mold Steel

Tlhaloso e Khutšoanyane:

DIN 1.2311 ″ ke mofuta o tloaelehileng oa tšepe ea hlobo, eo hangata e bitsoang tšepe ea P20. P20 ke tšepe e entsoeng ka tšepe e nang le alloy e tlaase e tsejoang ka ho sebetsa hantle le ho hanyetsa ho apara, e atisang ho sebelisoa ha ho etsoa liforomo tsa polasetiki le liforomo tse bolaeang.

DIN 1.2311 P20 Mold Steel:

DIN 1.2311 P20 Mold Steel ke tšepe ea hlobo e sebelisoang hangata, e sebelisoang haholo ha ho etsoa liforomo tsa polasetiki le li-molds tsa die-casting.DIN 1.2311 P20 Mold Steel e na le ts'ebetso e babatsehang ea ho itšeha le machinability, e etsang hore ho be bonolo ho sebetsana le mefuta e sa tšoaneng ea hlobo. e loketseng bakeng sa ho etsa liforomo tse nang le litlhoko tse phahameng.DIN 1.2311 P20 Mold Steel e atisa ho sebelisoa lits'ebetsong tse sa tšoaneng tsa hlobo tse kang li-ente, li-extrusion hlobo, li-die-casting hlobo, le li-mold bases.

Litlhaloso tsa 1.2311 TOOL Steels:

| Kereiti | 1.2311,P20 |

| Standard | ASTM A681 |

| Bokaholimo | Batsho; E peeled; E bentšitsoeng; E entsoe ka mochini; Ho sila; E retelehile; Milled |

| Lintho tse tala | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

1.2311 Mephato e Tšoanang ea tšepe:

| Naha | usa | Sejeremane | GB/T |

| Standard | ASTM A681 | DIN EN ISO 4957 | GB/T 1299 |

| Mephato | P20 | 1.2311 | 3Cr2Mo |

P20 TOOL Steels Sebopeho sa Lik'hemik'hale:

| Standard | Kereiti | C | Si | Mn | P | S | Cr | Mo |

| ASTM A681 | P20 | 0.28–0.40 | 0.2–0.8 | 0.60–1.0 | ≤0.030 | ≤0.030 | 1.4 - 2.0 | 0.3–0.55 |

| GB/T 9943 | 3Cr2Mo | 0.28–0.40 | 0.2–0.8 | 0.60–1.0 | ≤0.030 | ≤0.030 | 1.4 - 2.0 | 0.3–0.55 |

| DIN ISO4957 | 1.2311 | 0.35–0.45 | 0.2–0.4 | 1.3 ho isa ho 1.6 | ≤0.030 | ≤0.030 | 1.8–2.1 | 0.15–0.25 |

1.2311 Lisebelisoa tsa Mechini ea LITŠEPA TSA THUTO:

| Thepa | Metric |

| Thata, Brinell (Tlhaloso) | 300 |

| Hardness, Rockwell C (Tlhaloso) | 30 |

| Matla a Tensile, a ho qetela | 965-1030 MPa |

| Matla a Tensile, Kotulo | 827-862 MPa |

| Elongation Nakong ea Phomolo (Ka 50 mm (2″) | 20.00% |

| Matla a Khatellang | 862 MPa |

| Charpy Impact (V-Notch) | 27.1-33.9 J |

| Karolelano ea Poisson | 0.27-0.30 |

| Elastic modulus | 190-210 GPA |

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Litšebeletso tsa Rōna

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

4.CNC mechine

5.Ho cheka ka mokhoa o nepahetseng

6.Khaola likarolo tse nyane

7.Fihlella ho nepahala ha hlobo

Ho paka:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,