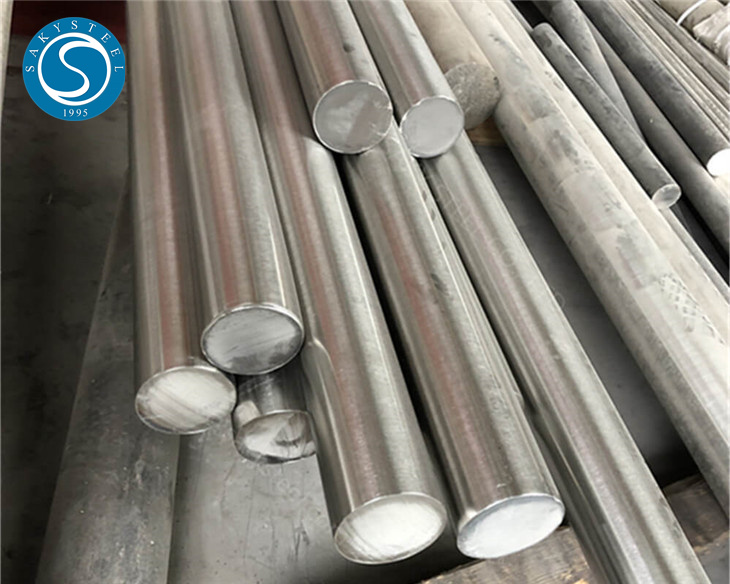

15-5PH Bare ea tšepe e sa hloekang

Tlhaloso e Khutšoanyane:

15-5 PH tšepe e sa jeleng paate ke tšepe e sa tsitsang e thata ea martensitic e fanang ka matla a phahameng, ho thatafala le ho hanyetsa ho bola. E sebelisoa hangata lits'ebetsong tse hlokang matla a holimo le boima bo kopantsoeng le khanyetso e ntle ea kutu.

15-5PH Sebaka sa tšepe e sa hloekang:

15-5PH bareng ea tšepe e sa hloekang ke mofuta o ikhethileng oa mochini o entsoeng ka tšepe ea 15-5 precipitation-hardening stainless steel.E fana ka matla a phahameng le ho thatafala, ho etsa hore e loketse lits'ebetso tse hlokang lisebelisoa tse matla. E fana ka khanyetso e ntle ea kutu, haholo-holo libakeng tseo ho tsona ho hlokahalang ho hanyetsa mocheso ho isa ho tse phahameng. boemo ba annealed, empa e ba phephetso ho mochine ka mor'a phekolo ea mocheso ka lebaka la boima ba eona bo eketsehileng.

Litlhaloso tsa 15-5PH Bar:

| Kereiti | 15-5PH,1.4545,XM-12 |

| Standard | ASTM A564 |

| Bolelele | Limithara tse 1 ho isa ho tse 6, Bolelele ba Setso ba Tloaelehileng |

| Ho qetela | E khanyang, ea Sepolishe le e Ntšo |

| Sebopeho | Round, Square, Hex (A/F), Rectangle, Wire (Coil Foromo), Wiremesh, Billet, Ingot, Forging jj. |

| Bokaholimo | Batsho; E peeled; E bentšitsoeng; E entsoe ka mochini; Ho sila; E retelehile; Milled |

| Boemo | Cold Drawn & polished Cold Drawn, Centreless Ground & polished |

| Lintho tse tala | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

15-5 PH Round Bar Tekanyetso E Tšoanang:

| TS'ELISO | UNS | WERKSTOFF NR. |

| 15-5 PH | S15500 | 1.4545 |

Sebopeho sa ASTM A564 XM-12 Bar Chemical:

| C | Si | Mn | P | S | Cr | Mo | Cu |

| 0.07 | 1.0 | 1.0 | 0.03 | 0.015 | 14.0-15.0 | 0.5 | 2.5-4.5 |

15-5 PH Thepa ea Mechini ea Libara tse Round:

| Tensile Strength (ksi) min | Elongation (% in 50mm) min | Matla a Kotulo 0.2% Bopaki (ksi) min | Ho thatafala |

| 190 | 10 | 170 | 388 |

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Litšebeletso tsa Rōna

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

4.CNC mechine

5.Ho cheka ka mokhoa o nepahetseng

6.Khaola likarolo tse nyane

7.Fihlella ho nepahala ha hlobo

Ho paka:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,