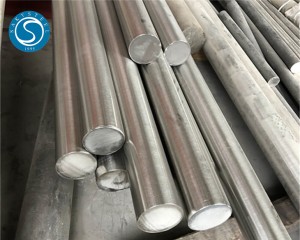

201J1 Tshipi e Sebeletsang Peipi e Welded

Tlhaloso e Khutšoanyane:

201J1 tšepe e sa jeleng paate ke mofuta oa austenitic chromium-nickel-manganese tšepe e sa hloekang.

Pipe e Welded ea 201J1 Stainless Steel:

201J1 tšepe e sa jeleng paate ke mofuta oa austenitic chromium-nickel-manganese tšepe e sa hloekang1. E ile ea ntlafatsoa ho boloka nickel 'me ke mokhoa o mong o theko e tlaase ho feta oa Cr-Ni o sa hloekang o tloaelehileng o kang 301 le 3041. Motsoako oa carbon oa 201J1 oa tšepe o sa hloekang o phahame hanyenyane ho feta oa 201J4, 'me bokahare ba koporo bo tlaase ho feta ba 201J42. Ts'ebetso ea eona ea ts'ebetso ha e ntle joalo ka ea 201J42.

Litlhaloso tsa Pipe e Welded ea 201J1 Stainless Steel:

| Kereiti | 201J1 |

| Litlhaloso | ASTM A/ASME A249, A268, A269, A270, A312, A790 |

| Bolelele | 5.8M,6M & Bolelele bo Hlokehang |

| Botenya | 0.3-20 limilimithara |

| Diameter | 6.00 limilimithara OD ho fihla ho 1500 limilimithara OD |

| Kemiso | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S |

| bokahodimo | Mill Finish, polishing(180#,180# hairline,240# hairline,400#,600#), Seipone jj. |

| Mofuta | Rtoa, Sekwere, Rectangle |

| Lintho tse tala | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

201J1 Sebopeho sa Likhemikhale tsa Pipe e Welded:

| Kereiti | C | Si | Mn | S | P | Cr | Mo | Ni | N | Cu |

| 201J1 | 0.12 | 0.8 | 9.0-11.0 | 0.008 | 0.050 | 13.50–15.50 | 0.6 | 0.9-2.0 | 0.10-0.20 | 0.70 |

Ke Hobane'ng ha U Re Khetha:

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

5. Fana ka tlaleho ea SGS TUV.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

7.Fana ka tšebeletso ea sebaka se le seng.

8.Lihlahisoa tsa rona li tsoa ka ho toba fekthering ea tlhahiso, ho netefatsa boleng ba pele le ho felisa litšenyehelo tse eketsehileng tse amanang le baemeli.

9.Re ikemiselitse ho fana ka litheko tse nang le tlhōlisano e kholo, e leng se u lumellang ho thabela melemo ea bohlokoa ea litšenyehelo ntle le ho sekisetsa boleng.

10.Ho fihlela litlhoko tsa hau hang-hang, re boloka thepa e ngata, ho netefatsa hore u ka fumana lihlahisoa tseo u li hlokang ka nako leha e le efe ntle le tieho.

Netefatso ea Boleng ea SAKY STEEL

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Tlhahlobo ea phello

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Teko ea ho Roughness

10. Metallography Teko ea Teko

Sephutheloana sa SAKY STEEL'S:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,