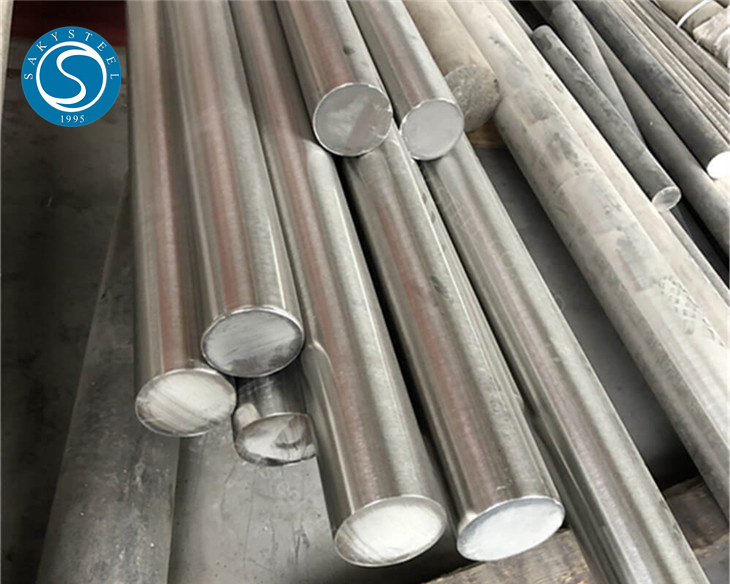

EN 1.4913 (X19CrMoNbVN11-1) Stainless Steel Bar

Tlhaloso e Khutšoanyane:

TS EN 1.4913 (X19CrMoNbVN11-1) Stainless Steel Bar ke alloy e sebetsang hantle haholo e etselitsoeng lits'ebetso tse maemong a mocheso o phahameng.

TS EN 1.4913 Bar ea tšepe e sa hloekang:

EN 1.4913 (X19CrMoNbVN11-1) stainless steel bar ke alloy e sebetsang hantle haholo e etselitsoeng lits'ebetso tse maemong a mocheso o phahameng. E entsoe ka chromium, molybdenum, niobium, le vanadium, e fana ka khanyetso e ntle ea oxidation, matla a ho hahaba, le ho tšoarella ha nako e telele. Thepa ena e loketse liindasteri tse kang ho fehla motlakase, ho sebetsa ka lik'hemik'hale, le sebaka sa sefofane, moo matla a holimo, a thibelang mocheso, le thepa e thibelang kutu e bohlokoa haholo. Botsitso ba eona bo phahameng ba mocheso bo etsa hore e be e loketseng ho sebelisoa likarolong tse kang li-boilers, li-heaters tsa mocheso, le li-turbine, moo ho sebetsang tlas'a maemo a feteletseng ho hlokahalang.

Litlhaloso tsa bar ea tšepe ea X19CrMoNbVN11-1:

| Litlhaloso | EN 10269 |

| Kereiti | 1.4913 ,X19CrMoNbVN11-1 |

| Bolelele | 1-12M & Bolelele bo Hlokehang |

| Surface Finish | E ntšo, e Khanyang |

| Sebopeho | Ratoa |

| QETA | Qetello e Ntle, Qetello e Beveled |

| Setifikeiti sa Tlhahlobo ea Mill | EN 10204 3.1 kapa EN 10204 3.2 |

1.4913 bareng ea tšepe e sa hloekang Sebopeho sa Lik'hemik'hale:

| Kereiti | C | Mn | P | S | Cr | Ni | Mo | Al | V |

| 1.4913 | 0.17-0.23 | 0.4-0.9 | 0.025 | 0.015 | 10.0-11.5 | 0.20-0.60 | 0.5-0.8 | 0.02 | 0.1-0.3 |

EN 1.4913 bar ea tšepe e sa hloekang e sebelisoa joang ka mocheso?

Ts'ebetso ea kalafo ea mocheso bakeng sa EN 1.4913 (X19CrMoNbVN11-1) bareng ea tšepe e sa hloekang e kenyelletsa tharollo ea tharollo, ho imolla khatello ea maikutlo le botsofali. Tharollo annealing hangata e etsoa pakeng tsa 1050 ° C le 1100 ° C ho homogenize sebopeho le ho qhaqha carbides, e lateloa ke ho pholisa ka potlako. Ho fokotsa khatello ea maikutlo ho etsoa ka 600 ° C ho isa ho 700 ° C ho tlosa khatello e setseng ho machining kapa welding. Botsofali bo etsoa ka 700°C ho isa ho 750°C ho matlafatsa matla le ho itoanela. Mehato ena ea kalafo ea mocheso e ntlafatsa khanyetso ea oxidation ea thepa e phahameng, matla a mochini, le khanyetso ea creep, e etsa hore e tšoanelehe bakeng sa ho batla lits'ebetso tse phahameng tsa mocheso.

Likopo tsa EN 1.4913 bar ea tšepe e sa hloekang?

TS EN 1.4913 (X19CrMoNbVN11-1) bar ea tšepe e sa jeleng paate e sebelisoa haholo lits'ebetsong tsa mocheso o phahameng le khatello e phahameng moo ho hlokahalang matla a ikhethang, ho hanyetsa oxidation le ho tšoarella ha nako e telele. Tse ling tsa lisebelisoa tsa mantlha li kenyelletsa:

1.Tlhahiso ea Motlakase: E sebelisoa lifemeng tsa motlakase, haholo li-turbine tsa mouoane, li-boilers le li-heaters tsa mocheso, moo ho hanyetsanang le mocheso o phahameng le ho bola ho leng bohlokoa.

2.Aerospace: E sebelisoa ka li-blade tsa turbine, likarolo tsa enjene, le likarolo tse ling tse phahameng tsa mocheso tse lokelang ho mamella mocheso o feteletseng le khatello ea indasteri ea sefofane.

3.Chemical Processing: E sebelisoa ka lik'hemik'hale tsa lik'hemik'hale, lihlahisoa tsa mocheso, le lisebelisoa tse ling tse pepesehileng tikolohong e senyang le mocheso o phahameng.

4.Indasteri ea Petrochemical: E loketse likarolo tsa limela tsa petrochemical, joalo ka li-reactors le li-piping system, tse sebetsang tlas'a khatello e phahameng ea mocheso le mochini.

5.Oil le Gas: E sebelisoa ho cheka le ho hloekisa lisebelisoa moo matla a mocheso o phahameng le ho hanyetsa oxidation le corrosion ke tsa bohlokoa bakeng sa ts'ebetso ea nako e telele.

6.Likaroloana tsa Boiler: E sebelisoa ha ho etsoa li-tubes tsa boiler, li-superheater tubes, le likarolo tse ling tsa bohlokoa tse pepesehileng tikolohong ea mocheso o phahameng oa mocheso.

7.Heat Exchangers: E sebelisoa ka har'a li-tubes le likaroloana tsa mocheso ka lebaka la bokhoni ba eona ba ho hanela libaesekele tse futhumatsang le ho senya ha mocheso o phahameng.

1.4913 (X19CrMoNbVN11-1) Litšobotsi tsa Bare

TS EN 1.4913 (X19CrMoNbVN11-1) ke alloy ea tšepe e sa sebetseng hantle e etselitsoeng mocheso o phahameng le likhatello tse phahameng, haholo indastering ea phepelo ea motlakase le ea petrochemical. Mona ke lintlha tsa bohlokoa tsa thepa ena:

1. Ho hanyetsana le Mocheso o Phahameng:Mocheso oa Mocheso: EN 1.4913 e etselitsoe ka ho khetheha ho mamella mocheso o phahameng, ho etsa hore e be e loketseng ho sebelisoa lifemeng tsa motlakase, li-turbine tsa mouoane, le libakeng tse ling tse nang le mocheso o phahameng.

2. E babatsehang Corrosion Resistance

Oxidation Resistance: E fana ka khanyetso e ntle ea oxidation, e etsa hore e loketse ho sebelisoa libakeng tse thata tse nang le mocheso o phahameng le mecha ea litaba e mabifi.

3. Matla a Molemo le Matla: Matla a Phahameng: EN 1.4913 e fana ka matla a matle ka mocheso o phahameng le ho boloka thepa ea eona ea mechine esita le tlas'a khatello le meroalo e phahameng.

4. Sebopeho sa Alloy: Lintho Tsa Bohlokoa: Alloy e na le Chromium (Cr), Molybdenum (Mo), Niobium (Nb), le Vanadium (V), e matlafatsang matla a eona le ho hanyetsa mocheso o phahameng. Sena se etsa hore e tšoanelehe bakeng sa ho pepesehela nako e telele libakeng tse phahameng tsa mocheso.

5. Molemo o Molemo oa ho Weldability le Formability: Welding: EN 1.4913 e ka chesetsoa ka mekhoa e tloaelehileng e kang TIG, MIG, le coated electrode welding, le hoja ho futhumatsa ho ka 'na ha hlokoa ho qoba ho thehoa ha mekhahlelo ea brittle.

6. Creep Resistance: The alloy e bonts'a khanyetso e ntle haholo, ho bolelang hore e boloka matla a eona ka nako e telele ea ho pepesehela mocheso o phahameng le khatello ea maikutlo, e leng ntho ea bohlokoa bakeng sa ts'ebeliso ea matla le tlhahiso ea matla.

7. Ho hanyetsa Mokhathala: E na le khanyetso e ntle ea mokhathala, ho bolelang hore e ka mamella mekoloko ea ho laela khafetsa, e leng ea bohlokoa bakeng sa likarolo tse itšetlehileng ka maemo a feto-fetohang a khatello ea kelello.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS, TUV, BV 3.2.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Ho Paka Litšepe Tsa Stainless Steel:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,