420 Bir-Flat Bir ah

Sharaxaad Gaaban:

Din 1.4034 SS 430 baararka fidsan, SS UNS S42000 baararka fidsan, birta aan fiicnayn 420 bar bar, 420 ahama birta qabow sawiran baararka alaab-qeybiyeyaasha Shiinaha.

Fasalka 420 birta aan la taaban karin waa bir kaarboon-sare oo leh ugu yaraan chromium ka kooban 12%. Sida birta kale ee kale, fasalka 420 waxa kale oo lagu adkeyn karaa daawaynta kulaylka. Waxay bixisaa ductility wanaagsan xaaladdeeda la jeexjeexay iyo guryaha iska caabinta daxalka oo aad u fiican marka birta la sifeeyo, oogada dhulka la dhigo ama la adkeeyo. Darajadani waxay leedahay engegnaanta ugu sareysa - 50HRC - marka lagu daro dhammaan darajooyinka birta aan la taaban karin ee leh 12% chromium.

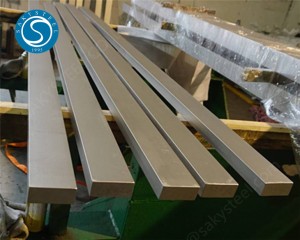

| 420 Astaamaha Birta fidsan ee birta ah: |

| Faahfaahin: | A276/484 / DIN 1028 |

| Qalabka: | 304 316 321 904L 410 420 2205 |

| Baararka Wareega ee Birta Aan-la-lahayn: | Dhexroor ka baxsan inta u dhaxaysa 4mm ilaa 500mm |

| Ballaca: | 1mm ilaa 500mm |

| Dhumucda: | 1mm ilaa 500mm |

| Farsamada: | Kulul La Dulmaray & La Qaaday (HRAP) & Qabow la sawiray & Warqad la been-abuuray & Goosha |

| Dhererka: | 3 ilaa 6 Mitir / 12 ilaa 20 cagood |

| Calaamadayn: | Cabbirka, Fasalka, Magaca wax-soo-saarka ee baararka/Qeybaha kasta |

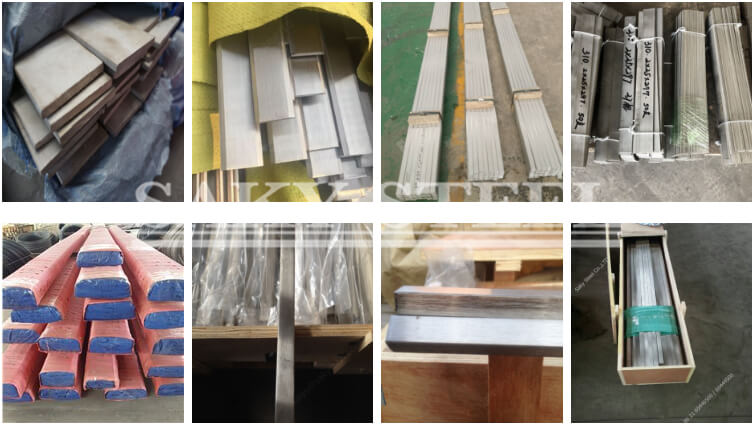

| Baakad: | Bir kastaa waxay leedahay hal-singal, qaar badanna waxaa lagu xidhi doonaa bacda tolmada ama sida looga baahan yahay. |

| Birta Aan Lahayn 420 Baararka Filat ee u dhigma: |

| HEERKA | JIS | SHAQADA NR. | BS | AFNOR | SIS | UNS | AISI |

| SS 420 | SUS 420 | 1.4021 | 420S29 | - | 2303 | S42000 | 420 |

| SS 420Baararka siman ee Kiimikada ah (birta saky): |

| Darajo | C | Mn | Si | P | S | Cr | Ni | Mo |

| SUS 420 | 0.15 max | 1.0 max | 1.0 max | 0.040 max | 0.030 max | 12.0-14.0 | - | - |

| SS 420 Flat Baars Guryaha makaanikada (birta saky): |

| Heerkulka Empering (°C) | Xoogga Jilitaanka (MPa) | Xoogga Wax-soo-saarka 0.2% caddayn (MPa) | Dheeraynta (% 50mm) | Hardness Brinell (HB) |

|---|---|---|---|---|

| La xiray * | 655 | 345 | 25 | 241 max |

| 399°F (204°C) | 1600 | 1360 | 12 | 444 |

| 600°F (316°C) | 1580kii | 1365 | 14 | 444 |

| 800°F (427°C) | 1620 | 1420 | 10 | 461 |

| 1000°F (538°C) | 1305 | 1095 | 15 | 375 |

| 1099°F (593°C) | 1035 | 810 | 18 | 302 |

| 1202°F (650°C) | 895 | 680 | 20 | 262 |

| * Guryaha jilcan ee jilicsan ayaa ah kuwa caadiga u ah Xaaladda A ee ASTM A276; engegnaanta la tirtiray waa ugu badnaan la cayimay. | ||||

| Xaqiijinta Tayada ee SAKY STEEL (oo ay ku jiraan kuwa wax baabi'iya iyo kuwa aan burburin labadaba): |

1. Tijaabada cabbirka muuqaalka

2. Baarista makaanikada sida xajinta, fidinta iyo dhimista aagga.

3. Baaritaanka Ultrasonic

4. Falanqaynta baaritaanka kiimikada

5. Imtixaan adag

6. Tijaabada ilaalinta godad

7. Tijaabada galmoodka

8. Tijaabada Daxalka Dhexdhexaadka ah

9. Falanqaynta saamaynta

10. Tijaabada Tijaabada Metallography

| Baakad |

1. Baakayntu aad bay muhiim u tahay gaar ahaan marka ay dhacdo shixnado caalami ah oo shixnaduhu ay soo maraan waddooyin kala duwan si ay u gaadhaan meesha ugu dambaysa, sidaas awgeed waxaanu walaac gaar ah saarnay baakadaha.

2. Saky Steel's waxay alaabtayada u xirtaa siyaabo badan oo ku salaysan alaabta. Waxaan u badeshaa alaabtayada siyaabo badan, sida,

Codsiyada:

Codsiyada u baahan iska caabbinta daxalka dhexdhexaadka ah iyo qalabka farsamada sare ayaa ku habboon Alloy 420. Tusaalooyinka codsiyada inta badan loo isticmaalo Alloy 420 waxaa ka mid ah:

Cutlery

Uumiga iyo marawaxadaha gaaska

Maacuunta jikada

Bolts, nuts, boolal

Qaybaha bamka iyo waalka iyo ulaha

Roogyada sallaankayga

Qalabka ilkaha iyo qalliinka

Nozzles

Kubadaha birta ah ee adag iyo kuraasta matoorada ceelasha saliidda