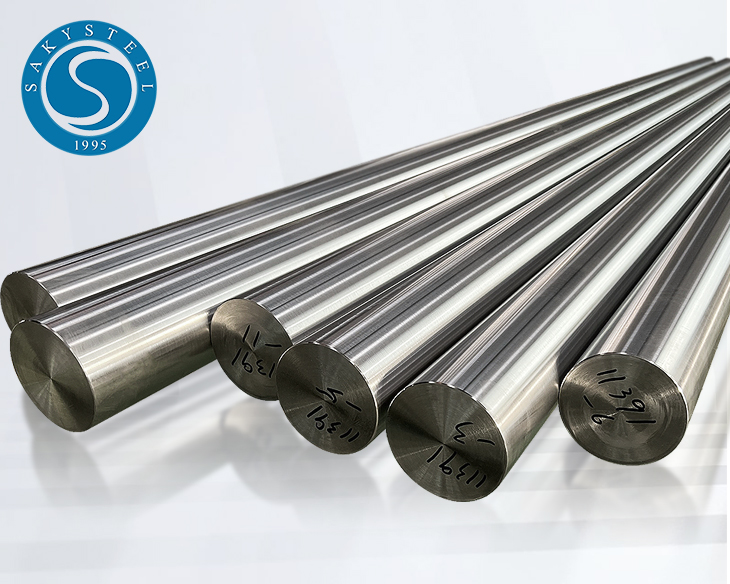

321 321H Stainless Steel bar

Tsanangudzo Pfupi

Ongorora misiyano yakakosha pakati pe321 ne321H simbi isina tsvina. Dzidza nezve yavo yepamusoro-tembiricha kuramba, zvivakwa, uye yakakodzera maapplication.

321 tsvimbo yesimbi isina tsvina:

Iyo 321 Stainless simbi bar is an austenitic Stainless simbi alloy ine titanium, iyo inopa yakanakisa kuramba kune intergranular corrosion kunyangwe mushure mekusangana netembiricha muchromium carbide kunaya kwe800 ° F kusvika 1500 ° F (427 ° C kusvika 816 ° C). Izvi zvinoita kuti zvive zvakanaka kuti zvishandiswe munzvimbo dzepamusoro-soro apo simbi inofanira kuchengetedza simba rayo uye kusagadzikana kwekuora. Zvishandiso zvakajairika zvinosanganisira exhaust manifolds, zvinopisa kupisa, uye zvikamu zveinjini dzendege. Kuwedzerwa kwetitanium kunogadzirisa alloy, kudzivirira carbide kuumbwa uye kuve nechokwadi chekugara kwenguva refu.

Zvinotsanangurwa zveSS 321 round bar:

| Giredhi | 304,314,316,321,321H nezvimwe. |

| Standard | ASTM A276 |

| Urefu | 1-12m |

| Diameter | 4.00 mm kusvika 500 mm |

| Condition | Cold Drawn & polished Cold Drawn, Peeled & Forged |

| Surface Finish | Dema, Kupenya, Kupenya, Yakakasharara Yakatendeuka, NO.4 Pedzisa, Matt Pedzisa |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Etc. |

| End | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 kana EN 10204 3.2 |

Stainless Simbi 321/321H Bhara Yakaenzana Magiredhi:

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

SS 321 / 321H Bhara Kemikari Kuumbwa:

| Giredhi | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) - 0.70 max |

| SS 321H | 0.04 - 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 4(C+N) - 0.70 max |

321 Stainless simbi bar application

1.Aerospace: Zvikamu zvakaita seanopopota masisitimu, manifolds, uye turbine injini zvikamu uko kuratidzwa kune tembiricha yakakwira uye nharaunda dzinoparadza zvinowanzoitika.

2.Chemical Processing: Zvishandiso zvakadai semagetsi ekupisa, zvigadziridzo zvemakemikari, uye matangi ekuchengetedza, uko kupikisa kune acidic uye corrosive zvinhu zvakakosha.

3.Petroleum Refining: Piping, heat exchangers, uye zvimwe zvigadzirwa zvinoratidzwa nepamusoro-tembiricha petroleum uye petrochemical process.

4.Power Generation: Boilers, midziyo yekumanikidza, uye zvimwe zvikamu mumagetsi emagetsi anoshanda pasi pekupisa kukuru uye kudzvinyirira.

5.Automotive: Exhaust systems, mufflers, uye catalytic converters inoda kupikisa kutonhora kwakanyanya uye oxidation.

6.Food Processing: Zvishandiso zvinofanirwa kutsungirira zvakadzokororwa kutenderera kwekudziya uye kutonhora, uchichengetedza hutsanana, senge mumukaka uye chikafu chekugadzira michina.

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

SS 321 round bar Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,