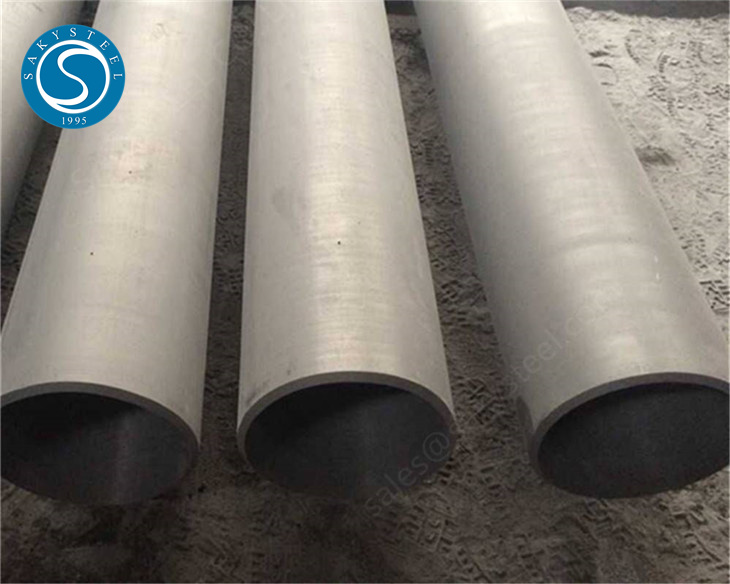

10Cr9Mo1VNbN Seamless Simbi Tubes

Tsanangudzo Pfupi

10Cr9Mo1VNbN simbi machubhu ane yakanakisa yepamusoro-tembiricha uye yakakwirira-kudzvinyirira kuramba, ichiita kuti ive yakakodzera mamiriro ekushanda munzvimbo dzine kupisa kwakanyanya uye kudzvanywa.

10Cr9Mo1VNbN Seamless Simbi Tubes:

10Cr9Mo1VNbN isimbi yakaderera-alloy inopa yakanakisa-yepamusoro-tembiricha zvivakwa uye kuramba kune ngura uye kukukurwa. Inoshandiswa zvakanyanya mumagetsi emagetsi boilers, uko inobata basa rakakosha pakuita kuti ive yakachengeteka uye yakavimbika kushanda pasi pekumanikidza kwakanyanya uye yakakwirira-tembiricha mamiriro. Zvimwe zvezvinhu zvakakosha zve10Cr9Mo1VNbN high-pressure seamless boiler tubes zvinosanganisira yakanakisa yepamusoro-tembiricha simba uye inokambaira, yakanaka corrosion kupikisa kune akasiyana magasi uye zvinwiwa zvinopisa, kutyisa kwakanyanya uye kutyisa kwemhepo kunyatsoita uye kupedzisa kwepamusoro, uye kuoma kwakanyanya uye ductility.

Zvinotsanangurwa zve10Cr9Mo1VNbN Tubes:

| Giredhi | 10Cr9Mo1VNbN,P90 |

| Standard | GB 5310-2008,GB /T 5310-2017 |

| Surface | Pickled, Sandblast, polishing, nezvimwewo |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

10Cr9Mo1VNbN Tube Chemical Kuumbwa:

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu |

| 0.08-0.12 | 0.20-0.50 | 0.30-0.60 | 0.025 | 0.010 | 8.0-9.5 | 1.0-1.2 | 0.40 | 0.20 |

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

Masevhisi Edu

1.Kudzima uye kupisa

2.Vacuum kupisa kurapa

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cheka muzvikamu zviduku

7.Achieve mold-kufanana nemazvo

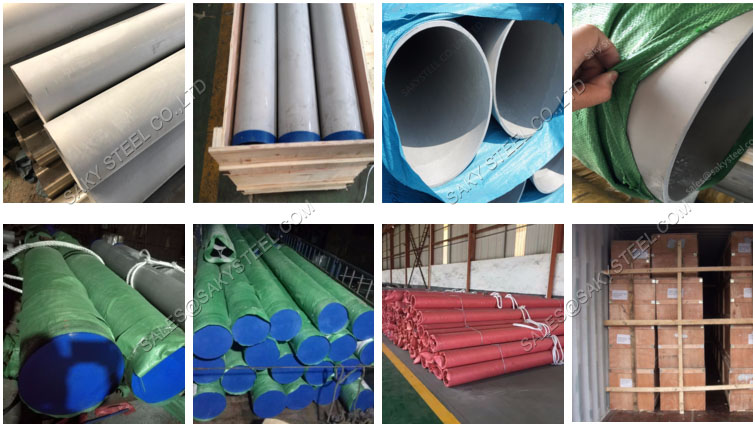

Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,