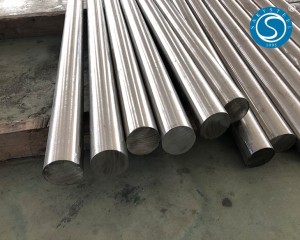

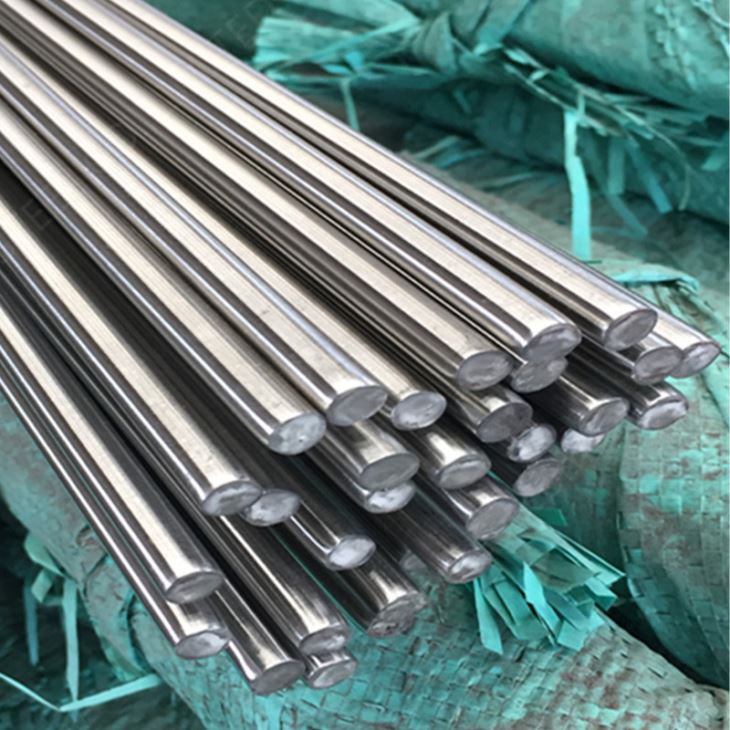

SUS hairline txhuam 310 Stainless Hlau Round Bar

Lus piav qhia luv luv:

Saky Steel's 310 stainless hlau bar, tseem hu ua UNS S31000 thiab Qib 310, muaj cov ntsiab lus hauv qab no: .25% siab tshaj carbon, 2% manganese siab tshaj plaws, 1.5% siab tshaj silicon, 24% mus rau 26% chromium, 19% mus rau 22% npib tsib xee, tracesphosphorus thiab sulfur. Saky Steel Hom 310 yog qhov zoo tshaj plaws nyob rau hauv feem ntau ib puag ncig rau 304 lossis 309 vim nws cov ntsiab lus siab chromium thiab npib tsib xee. Nws nthuav tawm kev sib xyaw ua ke ntawm lub zog zoo thiab kev tiv thaiv corrosion nyob rau hauv qhov kub txog li 2100 ° F. Kev ua haujlwm txias yuav ua rau 309 nce hardness thiab lub zog, thiab nws tsis teb rau kev kho cua sov.

| Specifications ntawmstainless hlau bar: |

Specifications:ASTM A276 thiab ASTM A314

Qib:310 310S, 310, 310s, 316

Ntev:5.8M, 6M & Ntev Ntev

Round Bar Txoj kab uas hla:4.00mm txog 500mm

Bright Bar:4mm-450mm,

Qhov xwm txheej:Cold Drawn & Polished Cold Drawn, Peeled & Forged

Nto tiav:Dub, Ci, Polished, Rough tig, NO.4 Finish, Matt Finish

Daim ntawv:Round, Square, Hex (A / F), Rectangle, Billet, Ingot, Forged Etc.

Xaus:Plain End, Beveled End

| 310 310s Stainless hlau Bar Chemical Composition: |

| Qib | C | Mn | Si | P | S | Cr | Ni |

| 310 | 0.25 max | 2.0 max | 1.5 max | 0.045 max | 0.030 max | 24.0-26.0 Nws | 19.0-22.0 Nws |

| 310S ib | 0.08 max | 2.0 max | 1.5 max | 0.045 max | 0.030 max | 24.0-26.0 Nws | 19.0-22.0 Nws |

| 310 310s Stainless hlau Bar MECHANICAL & PHYSICAL PROPERTIES: |

| Tensile zog (min) | Qhov siab tshaj plaws - 620 |

| Yield zog (0.2% Offset) | Ua haujlwm siab - 310 |

| Elongation | 30% |

| Vim li cas thiaj xaiv peb: |

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog cov ntaub ntawv pov thawj tiav, txoj cai los ntawm cov ntaub ntawv pov thawj cov ntaub ntawv raw mus rau qhov kawg seem nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kuaj

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

| SAKY STEEL Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel ntim peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,

Daim ntawv thov:

Rauv qhov chaw

Thaum tshav kub kub Exchangers

Daim Ntawv Zeb Khoom

Exhaust Parts hauv Gas Turbines

Dav Hlau Qhov Chaw

Cov Khoom Siv Roj Roj