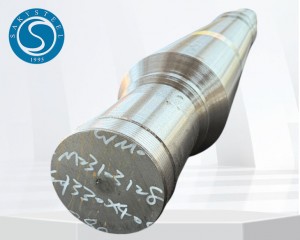

316 Forging Steel Roller Ncej

Lus piav qhia luv luv:

Tshawb nrhiav Forging Steel Roller Shafts rau cov ntawv thov kev lag luam. Kev cai ua rau koj cov kev qhia tshwj xeeb, nrog kev ua haujlwm ruaj khov thiab meej forging.

Forged Steel Roller Ncej

Forged Steel Roller Ncejyog lub zog muaj zog, ruaj khov siv nyob rau hauv ntau daim ntawv thov kev lag luam, tshwj xeeb tshaj yog nyob rau hauv kev tsim thiab ua cov ntaub ntawv xws li hlau, ntawv, thiab textiles. Tsim los ntawm cov txheej txheem forging, cov shafts muaj cov khoom siv zoo tshaj plaws, suav nrog kev txhim kho toughness, tsis kam hnav, thiab muaj peev xwm ntau dua load-bearing piv rau cam khwb cia lossis machined shafts. Forged Steel Roller Shafts yog tsim los ua kom tau raws li qhov loj me, cov duab, thiab cov kev xav tau ntawm kev ua haujlwm, kom ntseeg tau tias kev ua haujlwm ruaj khov thiab ua haujlwm ntev hauv kev ua haujlwm hnyav. Zoo tagnrho rau siv nyob rau hauv rollers, conveyors, thiab lwm yam machinery, lawv muab tshwj xeeb kev kawm nyob rau hauv high-stress tej yam kev mob.

Specifications ntawm Forged Steel Rolls:

| Specifications | ASTM A182, ASTM A105, GB / T 12362 |

| Khoom siv | Alloy steel, Carbon steel, Carburizing steel, quenched thiab tempered steel |

| Qib | Carbon Steel: 4130,4140,4145, S355J2G3 + N, S355NL + N, C20, C45, C35, thiab lwm yam. |

| Stainless hlau: 17-4 PH, F22,304,321,316/316L, thiab lwm yam. | |

| Cov cuab yeej hlau: D2 / 1.2379, H13 / 1.2344, 1.5919, thiab lwm yam. | |

| Nto tiav | Dub, Dawb, thiab lwm yam. |

| Kev kho cua sov | Normalizing, Annealing, Quenching & Tempering, Nto quenching, Case hardening |

| Tshuab dhos | CNC tig, CNC Milling, CNC tho txawv, CNC sib tsoo, CNC Drilling |

| Gear Machining | Iav Hobbing, Iav Milling, CNC Iav Milling, Iav txiav, Kauv iav txiav, Iav txiav |

| Mill Test Certificate | EN 10204 3.1 lossis EN 10204 3.2 |

Forging steel ncej siv:

1.Steel Kev Lag Luam: Forged Steel Roller Shafts yog siv dav hauv dov mills, uas lawv ua lub luag haujlwm tseem ceeb hauv kev tsim thiab tsim cov khoom hlau. Cov shafts no tiv taus siab zog thiab kub, kom ntseeg tau tias du thiab zoo ib yam hlau ua.

2.Paper thiab Pulp Kev Lag Luam: Hauv cov ntawv mills, cov shafts no yog siv rau hauv calenders, presses, thiab rollers, uas yog ib qho tseem ceeb rau kev tsim cov ntawv thiab cardboard. Lawv cov kav ntev thiab tsis kam hnav ua rau lawv zoo tagnrho rau kev tuav cov haujlwm siab thiab kev kub ceev.

3.Textile Kev Lag Luam: Forged Steel Roller Shafts yog siv rau hauv cov tshuab textile, xws li cov ntaub qhwv thiab cov khoom siv spinning, los txhawb cov chais thiab muab kev txav mus los thiab ruaj khov thaum lub sij hawm tsim cov ntaub.

4.Mining thiab Quarrying: Cov shafts no tseem ceeb hauv cov tshuab uas ua cov ntxhia, qhov uas lawv ua haujlwm hnyav thiab hnyav ua haujlwm. Lawv lub zog ua kom muaj kev ntseeg tau ntev thiab ua haujlwm zoo hauv crushers, mills, thiab conveyors.

5.Agricultural Equipment: Nyob rau hauv kev ua liaj ua teb machinery, xws li harvesters thiab threshers, Forged Steel Roller Shafts pab nyob rau hauv kev hloov thiab txav ntawm cov ntaub ntawv, kom ntseeg tau cov kev ua hauj lwm zoo ntawm cov cuab yeej raws li xav tau tej yam kev mob.

6.Automotive thiab Conveyor Systems: Forged Steel Roller Shafts yog siv nyob rau hauv tsheb tsim cov kab thiab conveyor systems, qhov uas lawv muab kev txhawb zog rau hnyav-duty rollers uas txav cov khoom raws li cov kab sib dhos.

7.Plastic thiab Roj Hmab Manufacturing: Cov shafts no yog siv nyob rau hauv extrusion machinery thiab lwm yam khoom siv nyob rau hauv cov yas thiab roj hmab industries, kom ntseeg tau cov kev ua tau zoo nyob rau hauv ib puag ncig uas zoo sib xws ceev thiab load-bearing yuav tsum tau.

Nta ntawm Bright Shaft Forgings:

1.High Strength thiab Toughness: Cov txheej txheem forging txhim kho cov hlau sab hauv cov qauv, ua rau cov ncej muaj zog thiab muaj zog dua rau kev ntxhov siab thiab cuam tshuam.

2.Txhim kho hnav tsis kam: Forged Steel Roller Shafts yog cov resistant rau hnav thiab puas, ua rau lawv zoo tagnrho rau hnyav-duty daim ntaub ntawv uas kev sib txhuam yog tas li.

3.Txhim kho qaug zog tiv thaiv: Vim lawv cov microstructure refined, cov shafts no tuaj yeem tiv taus rov qab thauj khoom thiab thauj mus los yam tsis muaj kev puas tsuaj lossis tsis muaj kev ncaj ncees.

4.Superior Load-Bearing Capacity: Forged Steel Roller Shafts yog tsim los tswj cov khoom hnyav yam tsis muaj deformation.

5.Corrosion Resistance: Nyob ntawm qib ntawm cov hlau siv thiab lwm yam kev kho deg ntxiv (xws li, txheej lossis kev kho cua sov).

6.Customizability: Forged Steel Roller Shafts tuaj yeem kho kom haum raws li qhov loj me, cov duab, thiab kev ua haujlwm.

7.High Temperature Resistance: Cov shafts no tuaj yeem ua tau nyob rau hauv qhov kub thiab txias.

8.Dimensional Accuracy: Cov txheej txheem forging tso cai rau kev ua siab ntev thiab siab qhov tseeb.

9.Durability thiab Longevity: Forged Steel Roller Shafts muaj lub neej ua haujlwm ntev dua piv rau lwm cov ntaub ntawv lossis kev tsim khoom vim lawv lub zog zoo dua thiab ua haujlwm ntev.

10.Impact Resistance: Cov txheej txheem ntawm forging txhim kho cov ncej lub peev xwm los tiv thaiv tam sim ntawd shocks lossis cuam tshuam.

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS, TUV, BV 3.2 qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

Forged Steel Shafts Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,