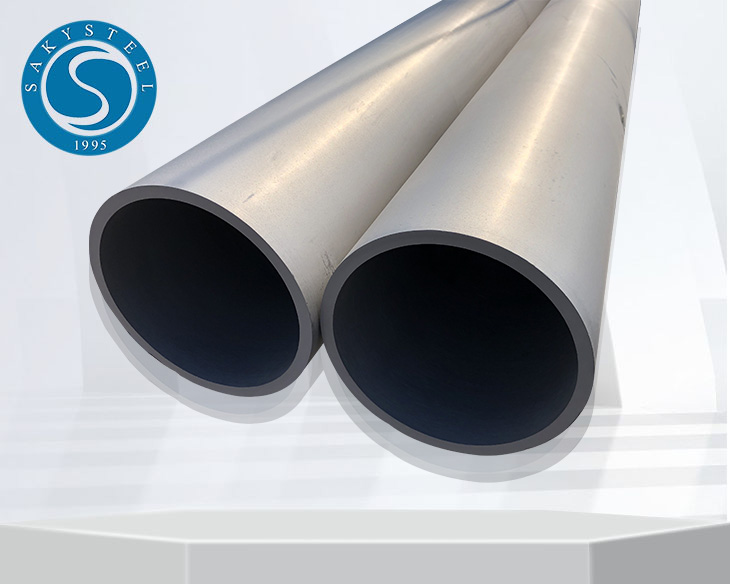

Stainless hlau 17-4 PH Tube

Lus piav qhia luv luv:

Tshawb xyuas peb Cov Hlau Stainless 17-4 PH Tube xaiv - muab lub zog zoo dua, tiv thaiv corrosion, thiab kev ua haujlwm. Zoo tagnrho rau aerospace, marine, thiab tshuaj industries.

Stainless hlau yeeb nkab Roughness Test:

Stainless Hlau 17-4 PH Yeeb Nkab Tube yog cov khoom muaj zog, corrosion-resistant khoom paub txog nws cov khoom zoo heev. Raws li nag lossis daus-hardening stainless hlau, nws muaj kev sib xyaw ua ke ntawm lub zog tensile siab, zoo toughness, thiab superior tsis kam rau oxidation thiab corrosive ib puag ncig. Qhov zoo tshaj plaws rau kev siv hauv aerospace, marine, chemical processing, thiab roj & roj industries, 17-4 PH yeeb nkab thiab raj tuav lawv lub zog txawm nyob rau hauv high-temperature thiab high-pressure tej yam kev mob, ua rau lawv ib tug ntau yam kev xaiv rau xav tau kev lag luam kev siv.

Specifications ntawm 17-4 PH Stainless Hlau Tube:

| Qib | 304,316,321,904L, thiab lwm yam. |

| Txuj | ASTM A / ASME SA213, A249, A269, A312, A358, A790 |

| Loj | 1/8 "NB rau 30" NB IN |

| Teem caij | TSW 20 SCH 30 SCH 40 XS STD SCH 80 SCH 60 SCH 80 SCH 120 SCH 140 SCH 160 XXS |

| Hom | Seamless, Welded |

| Daim ntawv | Rectangular, Round, Square, Capillary, thiab lwm yam |

| Ntev | 5.8M, 6M, 12M & Ntev Ntev |

| Xaus | Beveled End, Plain End, Treaded |

| Mill Test Certificate | EN 10204 3.1 lossis EN 10204 3.2 |

17-4PH SS Pipe Chemical Composition:

| Qib | C | Si | Mn | S | P | Cr | Ni | Cu |

| 17-4 PAB | 0.07 ib | 1.0 | 1.0 | 0.03 ib | 0.04 ib | 15.0-17.5 Nws | 3.0-5.0 Nws | 3.0-5.0 Nws |

Mechanical Properties ntawm 17-4PH Stainless Hlau Yeeb Nkab:

| Qib | Tensile zog (MPa) min | Elongation (% hauv 50mm) min | Yield zog 0.2% Pov thawj (MPa) min |

| 17-4 PAB | PSI – 170 000 | 6 | Psi – 140,000 |

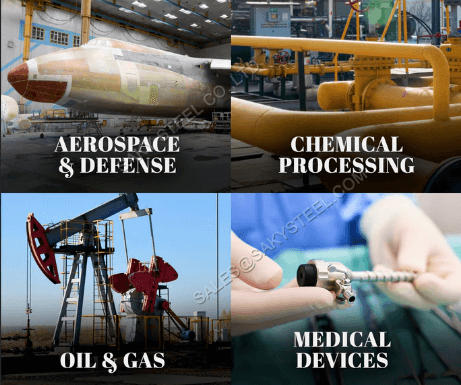

Daim ntawv thov scenarios rau stainless hlau 17-4 PH yeeb nkab

1.Aerospace:Siv rau hauv cov khoom siv thiab cov khoom siv dav hlau vim nws lub zog-rau-qhov hnyav piv.

2. Roj thiab Roj:Ua haujlwm nyob rau hauv cov kav dej rau nws tiv thaiv corrosion nyob rau hauv ib puag ncig hnyav.

3.Chemical Processing:Siv nyob rau hauv li qub, twj tso kua mis, thiab lwm yam khoom siv uas durability thiab tsis kam mus rau cov tshuaj yog ib qho tseem ceeb.

4.Marine Applications:Qhov zoo tshaj plaws rau cov khoom uas raug dej hiav txwv, vim nws tiv taus dej ntsev corrosion zoo.

5. Cov khoom siv kho mob:Siv rau hauv cov cuab yeej phais thiab kev cog hniav vim nws biocompatibility thiab lub zog.

Qhov zoo ntawm stainless hlau 17-4 PH yeeb nkab

1. Lub zog muaj zog:Muab lub zog tensile zoo thiab tawm los, ua rau nws tsim nyog rau kev thov.

2. Corrosion Resistance:Muab kev tiv thaiv zoo rau ntau yam corrosive ib puag ncig, txhim kho durability.

3.Heat Treatable:Nws tuaj yeem kho cua sov kom ua tiav cov khoom siv sib txawv, tso cai rau kev kho raws li cov kev xav tau tshwj xeeb.

4.Versatility:Haum rau ntau yam kev siv, los ntawm aerospace mus rau kev ua tshuaj lom neeg.

5.Zoo Fabricability:Yooj yim fabricated thiab welded, tso cai rau cov txheej txheem tsim tau zoo.

Vim li cas thiaj xaiv peb?

1. Nrog rau ntau tshaj 20 xyoo ntawm kev paub, peb pab neeg ntawm cov kws txawj ua kom zoo tshaj plaws nyob rau hauv txhua qhov project.

2.Peb ua raws li cov txheej txheem tswj hwm nruj kom ntseeg tau tias txhua yam khoom ua tau raws li cov qauv.

3.Peb leverage cov thev naus laus zis tshiab thiab cov kev daws teeb meem tshiab kom xa cov khoom zoo tshaj.

4.Peb muab cov nqi sib tw yam tsis muaj kev cuam tshuam rau qhov zoo, ua kom koj tau txais txiaj ntsig zoo tshaj plaws rau koj cov peev txheej.

5.Peb muaj ntau yam kev pab cuam kom tau raws li tag nrho koj cov kev xav tau, los ntawm kev sib tham thawj zaug mus rau kev xa khoom zaum kawg.

6.Peb txoj kev cog lus rau kev ruaj khov thiab kev coj ncaj ncees ua kom peb cov txheej txheem yog ib puag ncig zoo.

Quality Assurance:

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev xeem loj

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev xeem Flaring

8. Dej-Jet Test

9. Kev Xeem Penetrant

10. X-ray kuaj

11. Intergranular Corrosion Testing

12. Kev soj ntsuam cuam tshuam

13. Eddy kev tshuaj xyuas tam sim no

14. Hydrostatic tsom xam

15. Metallography Experimental Test

Corrosion-resistant Steel Pipe Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,