310 310S Stainless hlau seamless yeeb nkab

Lus piav qhia luv luv:

310/310S stainless hlau seamless kav, muab zoo heev kub tsis kam thiab corrosion kuj. Zoo tagnrho rauCov khoom siv hluav taws xob, cov khoom siv hluav taws xob, thiab kev siv hluav taws xob kub.

310 310S Stainless hlau seamless yeeb nkab:

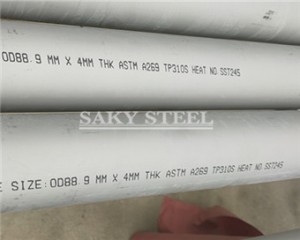

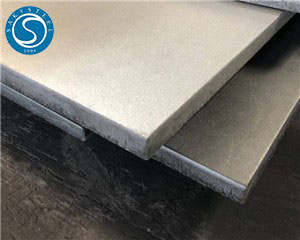

310/310S stainless hlau seamless yeeb nkab yog ib tug high-kev ua tau zoo, tshav kub-resistant alloy tsim rau huab cua kub. Ua los ntawm austenitic stainless hlau, nws muaj oxidation zoo heev thiab corrosion kuj mus txog 1100 ° C (2012 ° F). Cov pa roj carbon tsawg, 310S, txhim kho weldability thiab txo cov carbide nag lossis daus.Ua rau ASTM A312 thiab ASME SA312 cov qauv, cov kav dej no tau siv dav hauv cov khoom siv hluav taws xob, qhov cub, boilers, thiab petrochemical industries. Nrog rau qhov loj ntawm 1/8 "mus rau 24" (DN6-DN600) thiab muaj nyob rau hauv SCH10 mus rau SCH160 phab ntsa thickness, lawv ua kom muaj zog thiab ua haujlwm ntev. Kev cai qhov ntau thiab tsawg thiab tiav yog muaj raws li qhov kev thov.

Specifications ntawm Stainless Hlau Seamless Tube:

| Seamless Pipes & Tubes Loj | 1/8" NB - 12" NB |

| Specifications | ASTM A / ASME SA213, A249, A269, A312, A358, A790 |

| Qib | 304, 310, 310S, 314, 316, 321,347, 904L, 2205, 2507 |

| Cov txheej txheem | Kub dov, txias-draw |

| Ntev | 5.8M, 6M, 12M & Ntev Ntev |

| Sab nraud | 6.00 hli OD txog 914.4 hli OD |

| Thickness | 0.6mm txog 12.7mm |

| Teem caij | SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS |

| Hom | Seamless Yeeb Nkab |

| Daim ntawv | Round, Square, Rectangle, Hydraulic, Honed Tubes |

| Xaus | Plain End, Beveled End, Treaded |

| Mill Test Certificate | EN 10204 3.1 lossis EN 10204 3.2 |

310 / 310S Seamless Pipes Sib npaug Qib:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SIB 310 | 1.4841 ib | S31000 | SIB 310 | 310 S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SIB 310S | 1.4845 ib | S31008 | SUS 310 S | 310 S16 | 20 Nc23N18 | - | X8CrNi25-21 |

SS 310 / 310S Seamless Yeeb Nkab Siv Tshuaj:

| Qib | C | Mn | Si | P | S | Cr | Mo | Ni |

| SIB 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00-26.00 Nws | 0.10 max | 19.00-21.00 Nws |

| SIB 310S | 0.08 max | 2.0 max | max 1.00 Nws | 0.045 max | 0.030 max | 24.00-26.00 Nws | 0.75 max | 19.00-21.00 Nws |

Mechanical Properties ntawm 310/310S Stainless Hlau Yeeb Nkab:

| Qhov ntom | Melting Point | Tensile zog | Yield zog (0.2% Offset) | Elongation |

| 7,9g 3 | 1402 ° C (2555 ° F) | Psi - 75000, MPa - 515 | Psi - 30000, MPa - 205 | 40% |

Daim ntawv thov ntawm 310 Stainless hlau kav:

• Petrochemical & Refinery - Siv nyob rau hauv cov khoom siv hluav taws xob sib hloov thiab cov khoom siv rau hauv qhov cub

• Fais fab nroj tsuag – Boiler tubes, superheater tubes

• Aerospace & Marine – High-temperature structural Cheebtsam

• Khoom noj khoom haus & Pharmaceutical – Corrosion-resistant piping systems

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS TUV daim ntawv qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

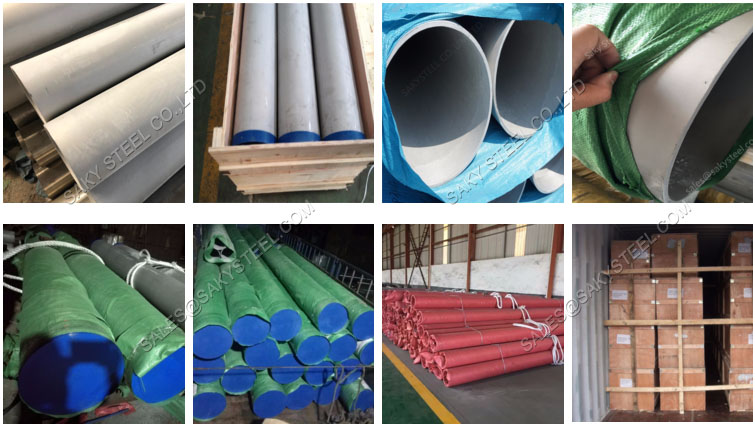

Corrosion-resistant Steel Pipe Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj dhau los ntawm ntau txoj kev mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel ntim peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,