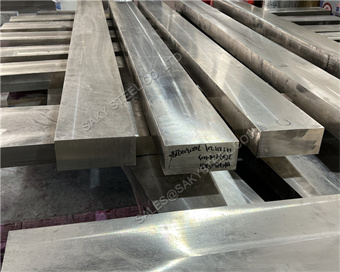

410 Stainless hlau tiaj tus Bar

Lus piav qhia luv luv:

UNS S41000 Flat Bars, SS 410 Flat Bars, AISI SS 410 Stainless Steel 410 Flat Bars Supplier, Chaw tsim tshuaj paus thiab Exporter nyob rau hauv Suav teb.

410 Stainless Hlau yog hardenable, ncaj-chromium stainless hlau uas sib xyaw superior hnav tsis kam ntawm high carbon alloys nrog rau corrosion kuj zoo heev ntawm chromium stainless hlau. Roj quenching cov alloys los ntawm qhov kub thiab txias ntawm 1800 ° F mus rau 1950 ° F (982-1066 ° C) ua rau lub zog siab tshaj plaws thiab / lossis hnav tsis kam nrog rau corrosion kuj. 410 Stainless Hlau yog siv qhov twg lub zog, hardness, thiab / los yog hnav tsis kam yuav tsum tau ua ke nrog corrosion kuj.

| 410 Stainless Hlau Flat Bar Specifications: |

| Specification: | A276/484/DIN 1028 |

| Khoom siv: | 303 304 316 321 410 420 ib |

| Stainless hlau Round Bars: | Sab nraud txoj kab uas hla ntawm 4mm mus rau 500mm |

| Dav: | 1mm txog 500mm |

| Thickness: | 1mm txog 500mm |

| Cov txheej txheem: | Kub Rolled Annealed & Pickled (HRAP) & Txias kos & Forged & Txiav Sheet thiab Coil |

| Ntev: | 3 mus rau 6 Meters / 12 mus rau 20 ko taw |

| Marking: | Loj, Qib, Tsim lub npe ntawm Txhua Bars / Pieces |

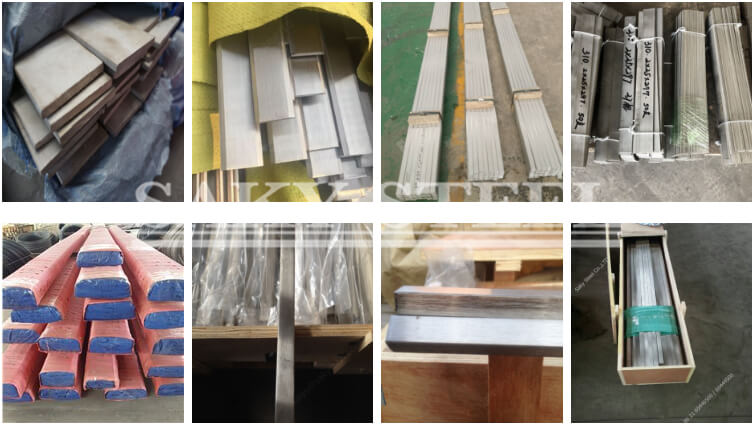

| Ntim: | Txhua lub steel bar muaj lub singal, thiab ob peb yuav tau bundled los ntawm lub hnab weaving los yog raws li ib tug yuav tsum tau. |

| Stainless hlau 410 Flat Bars sib npaug qib: |

| STANDARD | JIS | WERKSTOFF NR. | AFNOR | BS | GOST | UNS |

| SIB 410 | SIB 410 | 1.400 6 | Z12C13 | 410 S21 | - | S43000 |

| 410Flat Bars Chemical Composition thiab Mechanical Properties (saky steel): |

| Qib | C | Mn | Si | P | S | Cr | Ni |

| SIB 410 | 0.15 max | 1.0 max | 1.0 max | 0.040 max | 0.030 max | 11.5-13.5 Nws | 0.75 ib |

| Tensile zog | Yield zog (0.2% Offset) | Elongation (hauv 2 nti) |

| Ua haujlwm siab: 450 | MPa - 205 | 20% |

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Ultrasonic kuaj

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev soj ntsuam cuam tshuam

10. Metallography Experimental Test

| Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,

Daim ntawv thov:

Cov ntawv thov uas yuav tsum tau muaj kev tiv thaiv corrosion nruab nrab thiab cov khoom siv tshuab siab yog qhov zoo tagnrho rau Alloy 410. Piv txwv ntawm cov ntawv thov uas nquag siv Alloy 410 suav nrog:

Cov tais diav

Chav thiab roj turbine hniav

Chav ua noj

Bolts, ceev, screws

Pump thiab valve qhov chaw thiab shafts

Kuv ladder rugs

Cov cuab yeej kho hniav thiab phais

Nozzles

Hardened steel npas thiab cov rooj zaum rau cov roj zoo twj