2507 S32750 Super Duplex Round Bar

Lus piav qhia luv luv:

2507 stainless hlau yog super duplex stainless hlau paub txog nws zoo heev corrosion kuj thiab siab zog.

Super Duplex 2507 Round Bar:

2507 stainless hlau boasts tsis tshua muaj siab yield thiab tensile lub zog, ua rau nws haum rau high-kev nyuaj siab ib puag ncig.2507 stainless hlau puag ncig tuav ua exceptionally zoo nyob rau hauv ntau yam corrosive ib puag ncig, nrog rau tsis kam mus rau pitting thiab crevice corrosion nyob rau hauv chloride-muaj ib puag ncig.Txawm hais tias nws lub zog siab, 2507 stainless hlau puag ncig tuav 0 txheej txheem corrosive thiab rigidity. khaws nws cov khoom siv kho tshuab thiab corrosion kuj txawm nyob rau hauv high-temperature ib puag ncig.Siv rau cov khoom ntawm marine lug, ships, thiab offshore roj platforms.

Specifications ntawm 2507 steel bar:

| Qib | S32760 S31254 2507 S32750 |

| Specifications | ASTM A276, ASTM A276 |

| Ntev | 2.5M, 3M, 6M & Ntev Ntev |

| Txoj kab uas hla | 4.00mm txog 500mm |

| Loj | 6mm txog 120mm |

| Thickness | 100-6000 hli |

| nto | Bright, Dub, Polish |

| Hom | Round, Square, Hex (A / F), Rectangle, Billet, Ingot, Forging thiab lwm yam. |

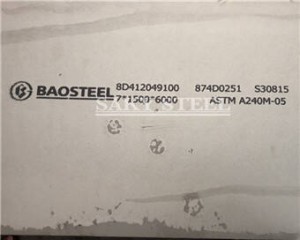

| Raw Khoom | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

S32750 Bar sib npaug qib:

| Qib | UNS | Werkstoff Nr. |

| 2507 ib | S32750 | 1.4410 Nws |

S32750 Duplex Bar Chemical Composition:

| Qib | C | Si | Mn | S | P | Cr | Mo | Ni |

| S32750 | 0.03 ib | 0.8 ua | 1.2 | 0.02 ib | 0.035 ib | 24.0-26.0 Nws | 3.0-5.0 Nws | 6.0-8.0 Nws |

2507 Duplex Bar Mechanical & Physical Properties:

| Yield zog (0.2% Offset) | Tensile zog | Elongation |

| 550 Mpa | 800 Mpa | 15% |

Vim li cas thiaj xaiv peb:

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib teev)

5. Muab SGS TUV daim ntawv qhia.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

7. Muab kev pabcuam ib-nres.

8.Our cov khoom tuaj ncaj qha los ntawm lub Hoobkas tsim, kom ntseeg tau zoo thawj thiab tshem tawm cov nqi ntxiv cuam tshuam nrog cov neeg nruab nrab.

9.Peb cog lus los muab cov nqi sib tw, uas tso cai rau koj kom txaus siab rau cov nqi zoo yam tsis muaj kev cuam tshuam rau qhov zoo.

Peb Cov Kev Pabcuam

1.Quenching thiab tempering

2.Nqus cua sov kho

3. Daim iav-polished nto

4.Precision-milled tiav

5. CNC machining

6.Precision drilling

7. Txiav rau hauv me me

8.Ua tiav pwm zoo li precision

SAKY STEEL Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,