2101 / S32101 Duplex Steel Yeeb Nkab

Lus piav qhia luv luv:

| Specifications ntawm 2101 duplex yeeb nkab: |

Specifications:ASTM A790 / ASME SA790 Cov Lus Qhia

Qib:2101/S32101

Loj:1/2 "NB TO 12" NB

Ntev:Ib qho Random, Ob Chav Random & Txiav Ntev.

Hom:Seamless / ERW / Welded / Fabricated / EFW

Teem caij:TXC 20 SCH 30 SCH 40 STD SCH 80 SCH 60 SCH 80 SCH 120 SCH 140 SCH 160 XXS

Raw Khoom:POSCO, Acerinox, Thyssenkrup, Baosteel, TISCO, nipponyakin, Nippon Steel Corporation, Saky Steel, Outokumpu

Daim ntawv:Round, Square, Rectangular, Hydraulic thiab lwm yam

Matching welding consumables:Vuam ntawm S32550 duplex steel sivER2594 vuam hlau.

| Stainless hlau S32101 Duplex yeeb nkab sib npaug qib: |

| STANDARD | WERKSTOFF NR. | UNS |

| S32101 | 1.4162 ib | S32101 |

| 1.4162 Duplex Tube Chemical Composition thiab Mechanical Properties: |

| Qib | C | Cr | Mn | N | Mo | Ni |

| S32101 | 0.04 max | 21.0-22.0 Nws | 4.0-6.0 max | 0.2-0.25 Nws | 0.1-0.8 hli | 1.35-1.7 Nws |

| Tensile zog | Yield zog (0.2% Offset) | Elongation (hauv 2 nti) |

| 690mpa ua | 485mpa ua | 36% |

| Vim li cas thiaj xaiv peb: |

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

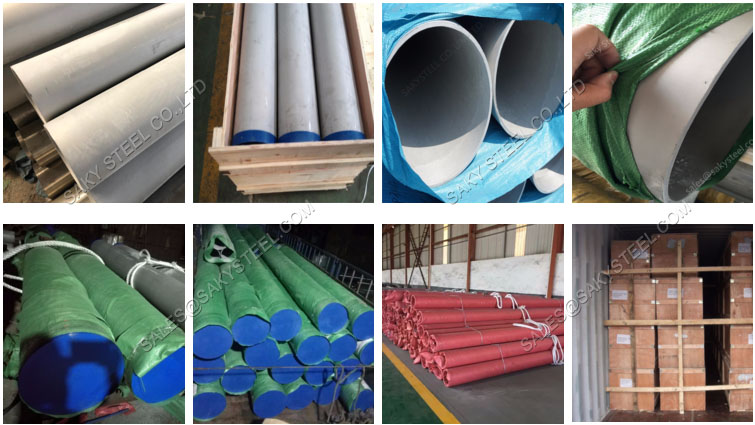

| SAKY STEEL Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,

Daim ntawv thov:

1. Roj thiab roj kev lag luam.

2.Petrochemical industries (polymerization reactor voj voog twj thiab kav dej)

3.Offshore platforms (kub exchangers, txheej txheem thiab kev pab cuam dej systems, hluav taws kub-tuag systems, thiab txhaj tshuaj thiab ballast dej systems)

4.Chemical process industries (heat exchangers thiab hlab ntsha)

5.Desalination nroj tsuag (siab siab RO-cog thiab seawater piping)

6.Fertilizers (Recirculation tanks, sedimentation tanks, phosphate reactor recirculation pumps)

7.Power kev lag luam FGD tshuab

8.Utility & industrial scrubber systems (absorber towers, ducting, piping)

9.Mining / Extraction (kub slurry yeeb nkab ua hauj lwm, acid leach mining)

10.Sewage (cov kav dej tseem ceeb heev.)

11.Engineering applications (cov hlab ntsha siab)