Paipu Kinohi Pilikino 316

ʻO ka wehewehe pōkole:

| Nā kikoʻī okuhiliʻole kila welded paipu: |

Ka nui o nā paipu a me nā paipu:1 / 8″ NB – 24″ NB

Nā kikoʻī:ASTM A/ASME A249, A268, A269, A270, A312, A790

Papa:304, 304L, 316, 316L, 316H, 316Ti, 321, 409L

Ka lōʻihi:5.8M,6M & Koi ʻia ka lōʻihi

Anawaena waho:6.00 mm OD a hiki i 1500 mm OD

mānoanoa :0.3mm – 20mm,

Hōʻike:SCH 5, SCH10, SCH 40, SCH 80, SCH 80S

Hoʻopau ʻili:Mill Finish, Polishing (180 #, 180 # hairline, 240 # hairline, 400 #,600 #), Mirror etc

Nā ʻano:Weled, EFW, ERW

ʻAno:Poʻai, ʻAha, ʻAhaʻahaʻa

Hoʻopau :Wela Plain, Wela Beveled

| Ke kila kila 316/316L/316H/316Ti Welded Paipu Kaulike Kaulike: |

| KANAWAI | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | - | Z7CND17-11-02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17-11-02 / Z3CND18-14-03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4401 | S31609 | SUS 316H | - | - | - | - |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17-123 | X6CrNiMoTi17-12-2 |

| SS316/316L/316H/316TiWelded Pipes Chemical Composition and Mechanical properties: |

| Papa | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316 | 0.08 ka nui | 2.0 ka nui | 1.0 ka nui | 0.045 ka nui | 0.030 ka nui | 16.00 – 18.00 | 2.00 – 3.00 | 11.00 – 14.00 | 67.845 min |

| SS 316L | 0.035 ka nui | 2.0 ka nui | 1.0 ka nui | 0.045 ka nui | 0.030 ka nui | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| SS 316H | 0.10 ka nui | 2.0 ka nui | 0.75 ka nui | 0.045 ka nui | 0.030 ka nui | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| SS 316Ti | 0.08 ka nui | 2.0 ka nui | 0.75 ka nui | 0.045 ka nui | 0.030 ka nui | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.395 min |

| ʻO ka mānoanoa | Lae hehee | Ikaika U'i | Ka ikaika o ka hua (0.2%offset) | ʻO ka lōʻihi |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| No ke aha e koho ai iā mākou: |

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi nei ua hiki ke hōʻoia ʻia, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope loa. (E hōʻike ʻia nā hōʻike ma ke koi)

4. e hōʻoiaʻiʻo e hāʻawi i ka pane i loko o 24 hola (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

| ʻO SAKY STEEL'S Quality Assurance (me nā mea hoʻopau a me ka hoʻopau ʻole): |

1. Ho'āʻo ʻana i ke ana ʻike

2. Mechanical nānā 'ana e like me tensile, Elongation a me ka ho'ēmi 'āpana.

3. Ka ho'āʻo nui

4. Ka nānā 'ana i ka ho'ā'o kemika

5. Hoao paakiki

6. Ho'āʻo pale lua

7. Ho'āʻo Flaring

8. Hoao Wai-Jet

9. Hoao Penetrant

10. X-ray hoao

11. Intergranular Corrosion Hoao

12. Ka nānā 'ana i ka hopena

13. Ho'āʻo hoʻokolohua Metallography

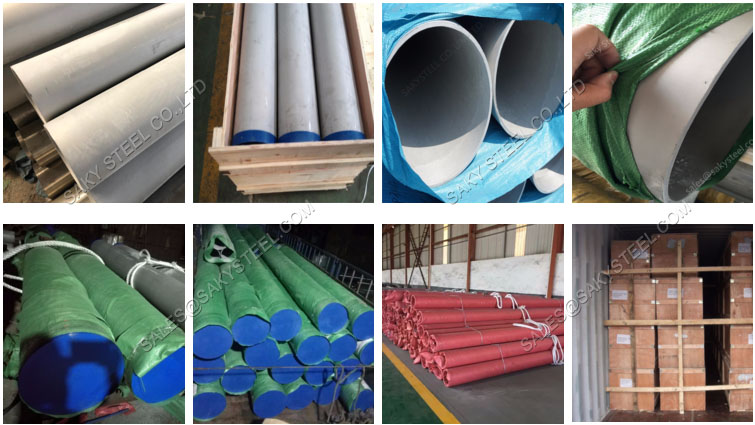

| SAKY STEEL'S Packaging: |

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka manaʻo nui e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana i nā ʻano he nui, e like me, Shrink-wrapped, pahu pahu pahu, pallet lāʻau, pahu lāʻau, pahu lāʻau.

Nā noi:

1. Nā ʻāpana kaʻa, Lapaʻau lapaʻau

2. Heat Exchanger, ʻOihana meaʻai

3. Mahiai, Uila, Kemika

4. Kemika lanahu; ʻImi ʻaila a me ke kinoea

5. Hoomaemae aila, Kinoea maoli; Mea hana