Duplex S31803 S32205 paipu ʻole

ʻO ka wehewehe pōkole:

| Duplex Steel S31803/S32205 Paipu a me nā Tubes kikoʻī: |

ʻO ka nui o nā paipu a me nā paipu ʻole:1 / 8″ NB – 12″ NB

Nā kikoʻī:ASTM A789, A790 / ASME SA789, SA790

Kūlana :ASTM, ASME a me API

Papa:S31803/2205, S32205/2205, S32750/2507;

ʻenehana:ʻOwili wela, huki anu

Ka lōʻihi:5.8M,6M & Koi ʻia ka lōʻihi

Anawaena waho:6.00 mm OD a hiki i 914.4 mm OD

mānoanoa :0.3mm – 50 mm,

Hōʻike:SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Nā ʻano:Paipu ʻole

ʻAno:Poe, huinaha, Rectangle, Hydraulic, Honed Tubes

Hoʻopau :Wehe Mahele, Wehe Beveled, Hehi

| Duplex Steel S31803/S32205 Paipu & Tubes Nā Papa Kaulike: |

| KUMU | WERKSTOFF NR. | UNS |

| Duplex S31803 / S32205 | 1.4462 | S31803 / S32205 |

| Duplex S31803 / S32205 Paipu, Hoʻohui Kemika Tubing a me nā waiwai Mechanical: |

| Papa | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 ka nui | 2.00 max | 1.00 max | 0.030 ka nui | 0.020 ka nui | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| S32205 | 0.030 ka nui | 2.00 max | 1.00 max | 0.030 ka nui | 0.020 ka nui | 21.0 – 23.0 | 2.50 – 3.50 | 4.50 – 6.50 | 0.08 – 0.20 | 63.54 min |

| ʻElemu | Māmā (g/cm 3) | Māmā (lb/in 3) | Lae hehee (°C) | Lae hehee (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

| No ke aha e koho ai iā mākou: |

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi nei ua hiki ke hōʻoia ʻia, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope loa. (E hōʻike ʻia nā hōʻike ma ke koi)

4. e hōʻoiaʻiʻo e hāʻawi i ka pane i loko o 24 hola (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

| ʻO SAKY STEEL'S Quality Assurance (me nā mea hoʻopau a me ka hoʻopau ʻole): |

1. Ho'āʻo ʻia ʻike

2. Mechanical nānā 'ana e like me tensile, Elongation a me ka ho'ēmi 'āpana.

3. Ka ho'āʻo nui

4. Ka nānā 'ana i ka ho'ā'o kemika

5. Hoao paakiki

6. Ho'āʻo pale lua

7. Ho'āʻo Flaring

8. Hoao Wai-Jet

9. Hoao Penetrant

10. X-ray hoao

11. Intergranular Corrosion Hoao

12. Ka nānā 'ana i ka hopena

13. Eddy e nānā nei

14. Hoʻopili hydrostatic

15. Ho'āʻo hoʻokolohua Metallography

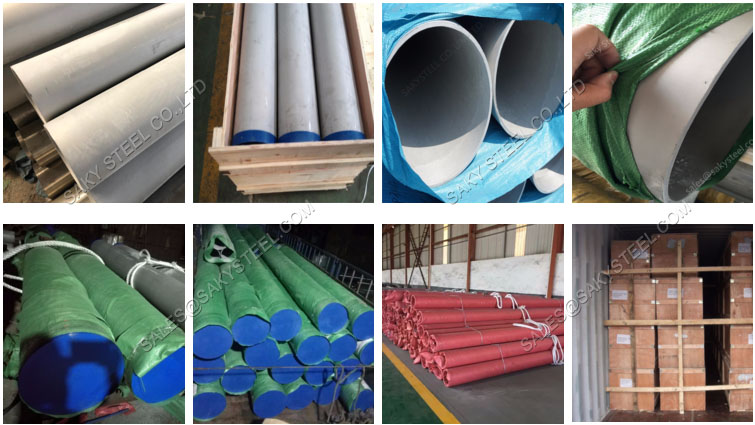

| SAKY STEEL'S Packaging: |

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,

Nā noi:

1. Hui Pepa & Pulp

2. Nā noi kiʻekiʻe

3. ʻOihana ʻaila a me ke kinoea

4. Mea Hana Kemika

5. Paipu

6. Hoʻohana wela kiʻekiʻe

7. Paipu wai Lin

8. Nā Mea Mana Nukelea

9. ʻOihana Meaʻai a me nā ʻoihana waiu

10. Ka paila a me nā mea hoʻololi wela