Bakin Karfe H Tashoshi

Takaitaccen Bayani:

"H Channels" suna nufin abubuwan da aka tsara kamar harafin "H" waɗanda aka fi amfani da su wajen gine-gine da aikace-aikace daban-daban.

Tashoshin Bakin Karfe H:

Tashoshin Bakin Karfe H abubuwa ne na tsari da aka siffantu da sashin giciyen su mai siffar H.An kera waɗannan tashoshi ne daga bakin karfe, gawa mai jure lalata da aka sani don dorewa, tsafta, da ƙawa.Tashoshi na Bakin Karfe H suna samun aikace-aikace a cikin masana'antu daban-daban, ciki har da gine-gine, gine-gine, da masana'antu, inda juriya na lalata da ƙarfin su ya sa su zama zaɓin da aka fi so don goyon baya da ƙira.Waɗannan abubuwan ana amfani da su sau da yawa a cikin ginin gine-gine, tallafi, da sauran su. abubuwa na tsari inda duka ƙarfi da kyakyawan bayyanar suke da mahimmanci.

Bayanin Tashoshin H:

| Daraja | 302, 304, 314, 310, 316, 321 da dai sauransu. |

| Daidaitawa | ASTM A276, GB/T 11263-2010, ANSI/AISC N690-2010, EN 10056-1: 2017 |

| Surface | zafi birgima pickled, goge |

| Fasaha | Hot Rolled , Welded |

| Tsawon | 1 zuwa 6 Mita |

Fasaloli & Fa'idodi:

•Zane-zanen sashin giciye mai siffar "H" na karfen I-beam yana ba da ƙwararriyar ƙarfin ɗaukar nauyi don duka a tsaye da kuma a kwance.

•Tsarin tsari na ƙarfe na I-beam yana ba da babban matakin kwanciyar hankali, hana nakasawa ko lankwasa a ƙarƙashin damuwa.

•Saboda siffa ta musamman, I-beam karfe za a iya sassauƙa a yi amfani da shi zuwa sassa daban-daban, gami da katako, ginshiƙai, gadoji, da ƙari.

•Karfe I-beam yana aiki na musamman da kyau a cikin lanƙwasa da matsawa, yana tabbatar da kwanciyar hankali a ƙarƙashin rikitattun yanayin lodi.

•Tare da ingantaccen ƙira da ƙarfin ƙarfinsa, ƙarfe na I-beam sau da yawa yana ba da ingantaccen farashi mai kyau.

•Ƙarfe na I-beam yana samun amfani mai yawa a cikin gine-gine, gadoji, kayan aikin masana'antu, da sauran fannoni daban-daban, yana nuna iyawar sa a cikin ayyukan injiniya daban-daban da tsarin.

•Tsarin ƙarfe na ƙarfe na I-beam yana ba shi damar dacewa da buƙatun ci gaba mai dorewa da ƙira, yana ba da ingantaccen tsarin tsari don ayyukan ginin muhalli da kore.

Abubuwan Haɗin Sinawa H Tashoshi:

| Daraja | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Kayayyakin Injini na Tashoshin H:

| Daraja | Ƙarfin Tensile ksi[MPa] | Yiled Strengtu ksi[MPa] | Tsawaita % |

| 302 | shafi na 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | shafi na 75[515] | 30[205] | 40 |

| 310 | shafi na 75[515] | 30[205] | 40 |

| 314 | shafi na 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | shafi na 75[515] | 30[205] | 40 |

Me yasa Zaba mu ?

•Kuna iya samun cikakkiyar kayan bisa ga buƙatun ku aƙalla farashin mai yiwuwa.

•Muna kuma bayar da Reworks, FOB, CFR, CIF, da farashin isar da kofa.Muna ba ku shawarar yin ciniki don jigilar kaya wanda zai zama mai fa'ida sosai.

•Abubuwan da muke samarwa ana iya tabbatar da su gaba ɗaya, tun daga takardar shaidar gwajin ɗanyen abu zuwa bayanin ƙima na ƙarshe. (Rahotanni za su nuna akan buƙata)

•Muna bada garantin bayar da amsa a cikin sa'o'i 24 (yawanci a cikin sa'a guda)

•Samar da rahoton SGS TUV.

•Muna da cikakkiyar sadaukarwa ga abokan cinikinmu.Idan ba zai yiwu ba don biyan bukatun ku bayan nazarin duk zaɓuɓɓuka, ba za mu ɓatar da ku ta hanyar yin alkawuran ƙarya wanda zai haifar da kyakkyawar dangantakar abokan ciniki.

•Samar da sabis na tsayawa ɗaya.

Menene hanyoyin walda?

Hanyoyin walda sun haɗa da waldawar arc, walƙiya garkuwar iskar gas (MIG/MAG waldi), walƙiya juriya, walƙiyar laser, walƙiya baƙar plasma, walƙiyar juzu'i, walƙiyar matsa lamba, walƙiyar katako na lantarki, da dai sauransu Kowace hanya tana da aikace-aikace na musamman da halaye, dacewa da daban nau'ikan kayan aiki da buƙatun samarwa.An yi amfani da baka don samar da yanayin zafi mai ƙarfi, narke ƙarfe a saman kayan aikin don samar da haɗin gwiwa.Hannun walda na yau da kullun sun haɗa da walƙiya na hannu, waldawar argon, walƙiya mai zurfi, da sauransu.Zafin da aka haifar da juriya ana amfani da shi don narke ƙarfe a saman kayan aikin don samar da haɗi.Weld ɗin juriya ya haɗa da walƙiya tabo, walƙiyar kabu da walƙiya.

Menene fa'idar waldawar baka?

Waldawar baka mai nutsewa ya dace da aiki da kai da mahalli mai girma.Yana iya kammala babban adadin aikin walda a cikin ɗan gajeren lokaci kuma ya inganta ingantaccen samarwa.Waldawar baka mai nutsewa ya dace da aiki da kai da mahalli mai girma.Yana iya kammala babban adadin aikin walda a cikin ɗan gajeren lokaci kuma ya inganta ingantaccen samarwa.An yi amfani da walda mai nutsewa a cikin ƙasa don walda zanen ƙarfe masu kauri saboda yawan shigar sa na yanzu da kuma babban shigarsa yana sa ya fi tasiri a waɗannan aikace-aikacen.Tun lokacin da aka rufe walda da juzu'i, ana iya hana iskar oxygen yadda ya kamata daga shiga yankin weld, ta yadda za a rage yuwuwar iskar oxygen da spatter.Idan aka kwatanta da wasu hanyoyin waldawar hannu, waldawar arc na nutsewa sau da yawa ana iya sarrafa ta cikin sauƙi, rage yawan buƙatun akan. basirar ma'aikaci.A cikin waldawar baka mai nutsewa, ana iya amfani da wayoyi masu yawa na walda da baka a lokaci guda don cimma burin walda mai yawa (multi-Layer) da haɓaka aiki.

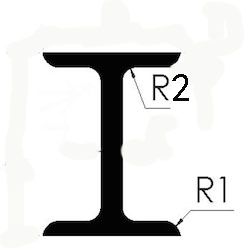

Gabatarwa ga siffar H katako ?

Siffar sashe na karfen I-beam, wanda akafi sani da "工字钢" (gōngzìgāng) a cikin Sinanci, yayi kama da harafin "H" lokacin buɗewa.Musamman, sashin giciye ya ƙunshi sanduna kwance biyu (flanges) a sama da ƙasa da mashaya ta tsakiya ta tsaye (yanar gizo).Wannan nau'in "H" yana ba da ƙarfi mafi girma da kwanciyar hankali ga karfe na I-beam, yana sanya shi kayan aiki na yau da kullum a cikin gine-gine da aikin injiniya. a matsayin katako, ginshiƙai, da tsarin gada.Wannan tsarin tsarin yana ba da damar I-beam karfe don rarraba kaya yadda ya kamata lokacin da aka yi wa sojoji, yana ba da tallafi mai ƙarfi.Saboda siffa ta musamman da halayen tsarinta, ƙarfe na I-beam yana samun amfani da yawa a fagagen gini da injiniyanci.

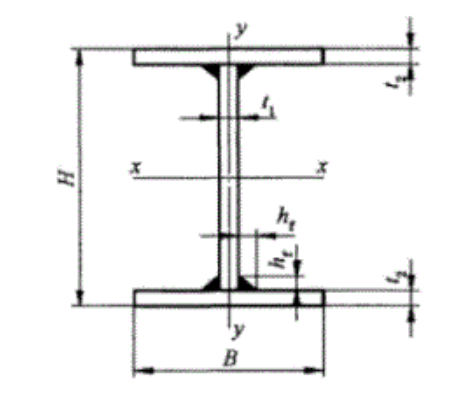

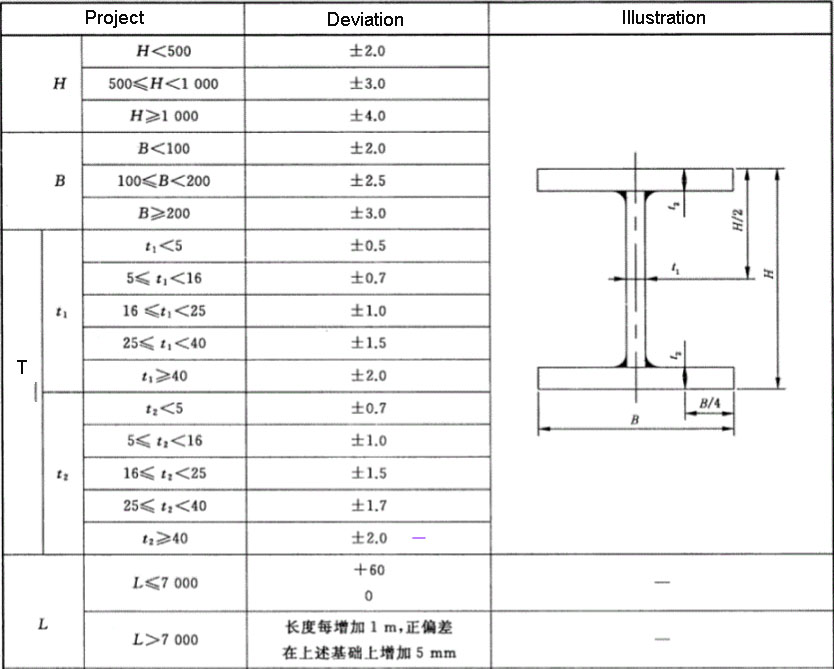

Yadda za a bayyana girman da magana na I-beam?

H-- Tsayi

B—— Fadi

t1——Kaurin yanar gizo

t2——kauri farantin Flange

h£—— Girman walda (lokacin da ake amfani da haɗin butt da fillet welds, yakamata ya zama girman girman ƙafar walda mai ƙarfafa hk)

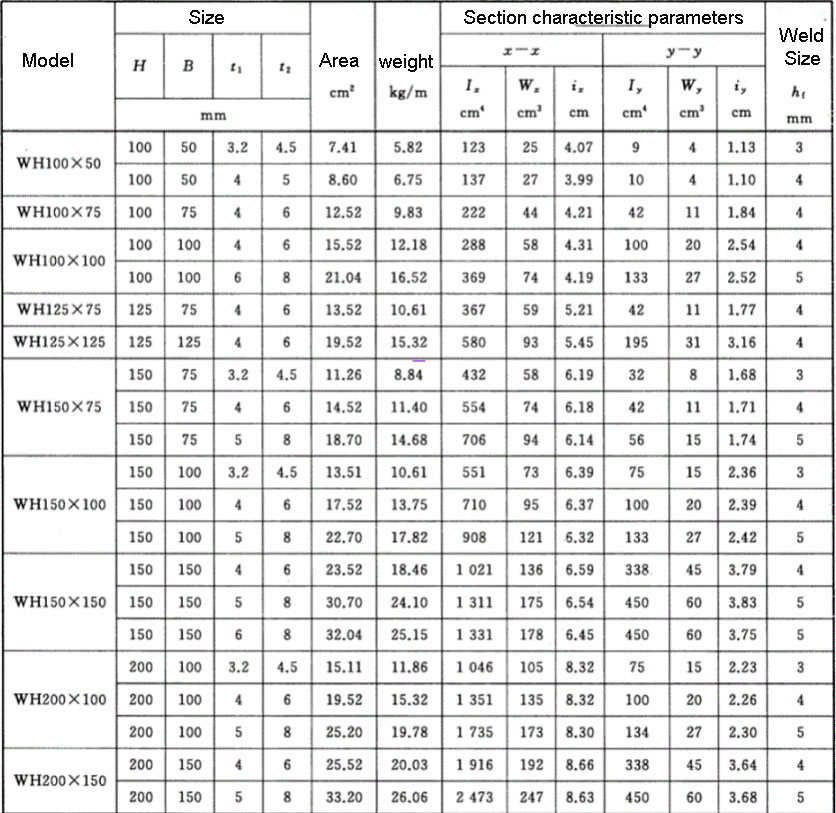

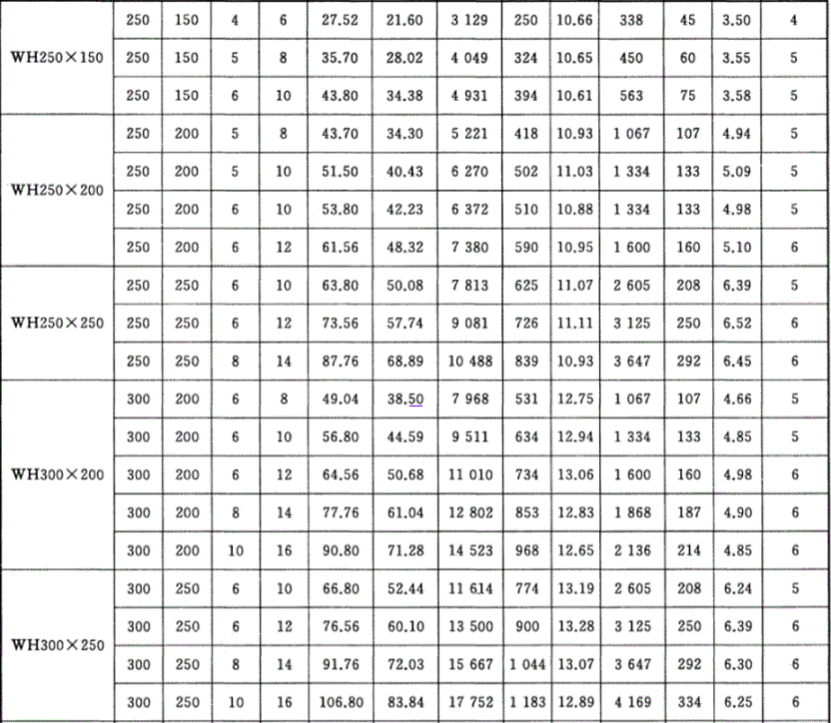

Girma, siffofi da rarrabuwar kawuna na welded H mai siffar karfe

Matsakaicin ma'auni, yanki na giciye, nauyin ka'ida da sifofin halayen giciye na welded H-dimbin ƙarfe

Abokan cinikinmu

Ra'ayoyi Daga Abokan Ciniki

Bakin Karfe H Tashoshi ɗimbin kayan gini ne waɗanda aka ƙera daga ƙarfe mai inganci.Wadannan tashoshi suna nuna siffar "H" ta musamman, suna ba da ƙarfin ƙarfafawa da kwanciyar hankali ga aikace-aikacen gine-gine da gine-gine daban-daban. Ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙarfe na ƙarfe yana ƙara daɗaɗɗen haɓakawa, yana sa waɗannan tashoshi na H sun dace da duka kayan aiki da kayan aiki na gani. Tsarin H-dimbin ƙira yana haɓaka ƙarfin ɗaukar nauyi, yana sa waɗannan tashoshi su dace don tallafawa nauyi mai nauyi a cikin gini da saitunan masana'antu.Tashoshin Bakin Karfe H suna samun aikace-aikace a cikin masana'antu daban-daban, gami da gine-gine, gine-gine, da masana'antu, inda ingantaccen tallafin tsarin ke da mahimmanci.

Shiryawa:

1. Yin kaya yana da matukar mahimmanci musamman a yanayin jigilar kayayyaki na kasa da kasa wanda jigilar kayayyaki ke bi ta hanyoyi daban-daban don isa wurin da ake bukata, don haka mun sanya damuwa na musamman game da marufi.

2. Saky Steel's fakitin kayanmu ta hanyoyi da yawa dangane da samfuran.Muna tattara samfuranmu ta hanyoyi da yawa, kamar,