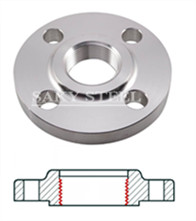

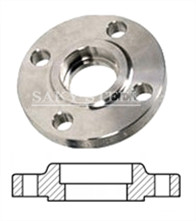

I-Stainless Steel Socket Welding Flanges

Incazelo emfushane:

I-Saky steel ingumkhiqizi ongcono kakhulu, umphakeli, kanye nomthekelisi wekhwalithi enhle kakhulu yamaflange ensimbi engagqwali. Saziwa kakhulu abakhiqizi abasebenza emhlabeni jikelele futhi banikeza ama-SS flange kumakhasimende ngokwezindinganiso zabo kanye nezidingo zokucaciswa kwazo. Ama-flange esiwahlinzekayo ayiringi engumgunyathi noma ekhonjiwe ethuthukiswe ukuxhuma izigaba zamapayipi nanoma yimuphi omunye umshini odinga izindawo zokuxhuma ezimaphakathi. Ama-flanges asetshenziselwa ukujoyina omunye nomunye ngokusebenzisa i-bolting noma ahlanganiswe ohlelweni lwamapayipi ngokusebenzisa intambo noma i-welding.

| Imininingwane ye-SInsimbi engagqwaliI-Socket WeldingAma-Flanges: |

I-Slip-On WeldingUsayizi we-Flangs:1/2″ (15 NB) ukuya ku-48″ (1200NB)

Imininingwane : I-ASTM A182 / ASME SA182

Okujwayelekile :ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, njll.

Ibanga:304, 316, 321, 321Ti, 347, 347H, 904L, 2205, 2507

Ikilasi / Ingcindezi :150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 njll.

Uhlobo lobuso be-Flange :I-Flate Face (FF), Ubuso Obuphakanyisiwe (RF), I-Ring Type Joint (RTJ)

| I-ASTM A182 Stainless Steel Flanges / ANSI b16.5 SS Flanges: |

|  |  |

| 316 Weld Neck Forged Flange | I-316 Lap Joint Forged Flange | 316 I-Flange Eyenziwe Ngentambo |

|  |  |

| 316 I-Blind Forged Flange | 316 Slip ku-Forged Flange | 316 Socket Weld Forged Flange |

| Kungani Ukhetha Thina : |

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Ungathola ezinye izindlela zesitoko, ukulethwa komshini ngokunciphisa isikhathi sokukhiqiza.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

| Ukuqinisekisa Ikhwalithi (okuhlanganisa kokubili Okubhubhisayo Nokungabhizi) : |

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Isivivinyo esikhulu

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Flaring Testing

8. Ukuhlolwa kweJet-Wamanzi

9. Isivivinyo Esingena Ngaphakathi

10. Ukuhlolwa kwe-X-ray

11. I-Intergranular Corrosion Testing

12. Ukuhlaziywa komthelela

13. Eddy ukuhlolwa kwamanje

14. Ukuhlaziywa kwe-Hydrostatic

15. Ukuhlolwa Kokuhlola Kwe-Metallography

| Ukupakishwa: |

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,

Izicelo:

1. Oomakhenikha

2. Amapayipi amanzi

3. Ezogesi

4. Izizukulwane zamandla

5. Izishintshi zokushisa

6. Imithi