Ⅰ.Umqondo oyisisekelo wokwelapha ukushisa.

A.Umqondo oyisisekelo wokwelapha ukushisa.

Izakhi eziyisisekelo kanye nemisebenzi yeukwelashwa ukushisa:

1.Ukushisa

Inhloso ukuthola umfaniswano kanye nesakhiwo esihle se-austenite.

2.Ukubamba

Umgomo uwukuqinisekisa ukuthi isiqeshana somsebenzi sishisisa kahle futhi sivimbele ukukhishwa kwe-carburization kanye ne-oxidation.

3.Ukupholisa

Inhloso ukuguqula i-austenite ibe ama-microstructures ahlukene.

Ama-Microstructures Ngemva Kokwelashwa Kokushisa

Phakathi nenqubo yokupholisa ngemva kokushisa nokubamba, i-austenite ishintsha ibe ama-microstructures ahlukene kuye ngesilinganiso sokupholisa. Ama-microstructures ahlukene abonisa izakhiwo ezahlukene.

B. Umqondo oyisisekelo wokwelapha ukushisa.

Ukwahlukaniswa Ngokusekelwe Ezindleleni Zokushisisa Nezokupholisa, kanye Nesakhiwo Esincane Nezakhiwo Zensimbi

1. Ukwelashwa Kokushisa Okujwayelekile (Ukwelashwa Kokushisa Sekukonke):Ukushisa, Ukukhipha, Ukujwayela, Ukucisha

2.Ukwelashwa Kokushisa Okungaphezulu: Ukucisha Ukushisa Okungaphezulu, Ukucisha Indawo Yokushisa Okungeniswayo, Ukucisha Indawo Yokushisa Komlilo, Ukucinywa Kokushisa Kokuthintana Nogesi.

3.Ukwelashwa Kokushisa Kwekhemikhali:Carburizing,Nitriding,Carbonitriding.

4.Okunye Ukwelashwa Kokushisa: Ukwelashwa Kokushisa Kwe-Atmosphere, Ukwelashwa Kokushisa Kwe-Vacuum, Ukwelashwa Kokushisa Okuguquguqukayo.

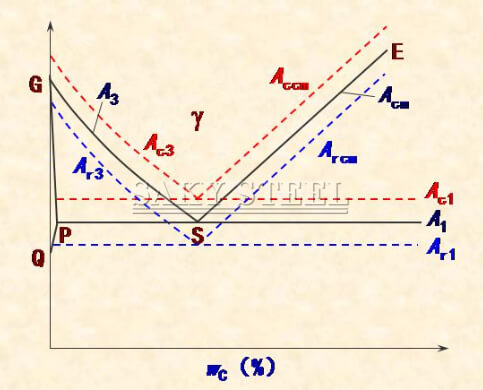

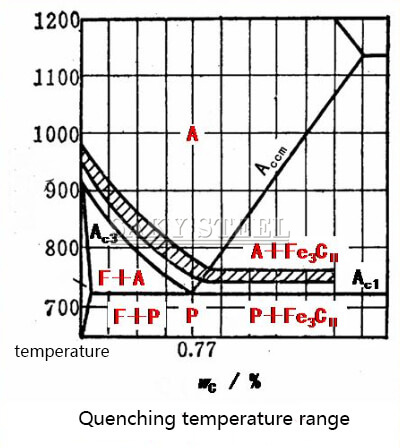

C.Izinga Lokushisa Elibucayi Lezinsimbi

Ukushisa okubalulekile kokuguqulwa kwensimbi kuyisisekelo esibalulekile sokunquma izinqubo zokushisa, zokubamba, nokupholisa ngesikhathi sokwelashwa kokushisa. Kunqunywa umdwebo wesigaba se-iron-carbon.

Isiphetho Esibalulekile:Izinga lokushisa langempela lokuguqulwa okubalulekile kwensimbi lihlala lisilela ngemuva kwezinga lokushisa elibucayi lethiyori. Lokhu kusho ukuthi ukushisa ngokweqile kuyadingeka ngesikhathi sokushisa, futhi ukufudumala kuyadingeka ngesikhathi sokupholisa.

Ⅱ.Ukukhipha kanye Nokujwayela Kwensimbi

1. Incazelo ye-Annealing

Ukufaka insimbi kuhlanganisa ukushisisa insimbi ezingeni lokushisa elingaphezulu noma elingaphansi kwephuzu elibalulekile i-Ac₁ ukuyibamba kulelo zinga lokushisa, bese uyipholisa kancane, ngokuvamile ngaphakathi kwesithando somlilo, ukuze kuzuzwe isakhiwo esiseduze nokulingana.

2. Inhloso Yokuhlanganisa

①Lungisa Ukuqina Komshini: Ukuzuza ubulukhuni obuphathekayo ebangeni le-HB170~230.

②Yehlisa Ukucindezeleka Okusele: Ivimbela ukuguquguquka noma ukuqhekeka phakathi nezinqubo ezilandelayo.

③Lungisa Isakhiwo Sokusanhlamvu: Sithuthukisa isakhiwo esincane.

④Ukulungiselela Ukwelashwa Kokugcina Kokushisa: Ithola i-granular (spheroidized) pearlite yokucisha nokuthambisa okulandelayo.

3.Spheroidizing Annealing

Ukucaciswa Kwenqubo: Izinga lokushisa elishisayo liseduze nendawo ye-Ac₁.

Inhloso: Ukwenza i-spheroidize i-cementite noma i-carbides ensimbi, okuholela ku-granular (spheroidized) pearlite.

Ibanga Elisebenzayo: Isetshenziselwa izinsimbi ezine-eutectoid kanye ne-hypereutectoid compositions.

4.I-Diffusing Annealing (I-Homogenizing Annealing)

Ukucaciswa Kwenqubo: Izinga lokushisa elishisayo lingaphansi kancane komugqa we-solvus kumdwebo wesigaba.

Inhloso: Ukuqeda ukuhlukana.

①Okuphansi-insimbi ye-carbonngokuqukethwe kwekhabhoni engaphansi kuka-0.25%, ukujwayela kuyakhethwa kune-annealing njengokwelapha okulungiselela ukushisa.

②Ngensimbi enekhabhoni emaphakathi enokuqukethwe kwekhabhoni phakathi kuka-0.25% no-0.50%, i-annealing noma i-normalization ingasetshenziswa njengokwelashwa kokulungiselela ukushisa.

③Ngensimbi enekhabhoni ephakathi nendawo ukuya phezulu enokuqukethwe kwekhabhoni phakathi kuka-0.50% no-0.75%, ukudonsa okugcwele kuyanconywa.

④Okwezinga eliphezulu-insimbi ye-carbonngokuqukethwe kwekhabhoni okukhulu kuno-0.75%, ukujwayela kuqala kusetshenziselwa ukuqeda inethiwekhi ye-Fe₃C, kulandele i-spheroidizing annealing.

Ⅲ.Ukucishwa Nokushiswa Kwensimbi

A.Quenching

1. Incazelo Yokucisha: Ukucisha kuhlanganisa ukushisisa insimbi ezingeni lokushisa elithile elingaphezu kwephoyinti le-Ac₃ noma le-Ac₁, ukuyibamba kulelo zinga lokushisa, bese uyipholisa ngesilinganiso esikhulu kunesilinganiso sokupholisa esibalulekile ukuze kwakhe i-martensite.

2. Injongo Yokuqeda: Umgomo oyinhloko ukuthola i-martensite (noma ngezinye izikhathi i-bainite ephansi) ukuze kwandiswe ubulukhuni nokumelana nokugqoka kwensimbi. Ukucisha kungenye yezinqubo ezibaluleke kakhulu zokwelashwa kokushisa kwensimbi.

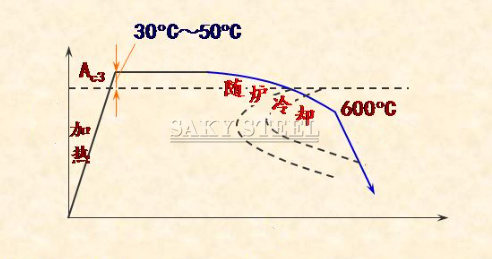

3.Ukunquma Amazinga Okushisa Okucisha Izinhlobo Ezihlukene Zensimbi

Insimbi ye-Hypoeutectoid: Ac₃ + 30°C kuya ku-50°C

Insimbi ye-Eutectoid ne-Hypereutectoid: Ac₁ + 30°C kuya ku-50°C

I-alloy Steel: 50°C kuya ku-100°C ngaphezu kwezinga lokushisa elibucayi

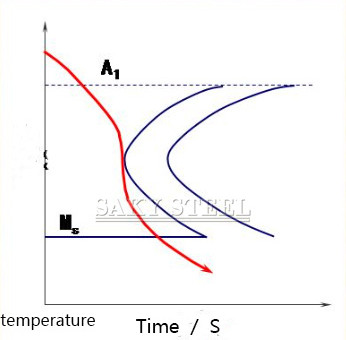

4.Izici Zokupholisa Zendawo Ekahle Yokucisha:

Ukupholisa Okunensayo Ngaphambi Kokushisa "Kwekhala": Ukunciphisa ngokwanele ukucindezeleka okushisayo.

Amandla Okupholisa Aphezulu Eduze Kwezinga Lokushisa "Ikhala": Ukugwema ukwakheka kwezakhiwo ezingezona ze-martensitic.

Ukupholisa Okunensayo Eduze Kwephuzu elingu-M₅: Ukunciphisa ingcindezi ebangelwa ukuguqulwa kwe-martensitic.

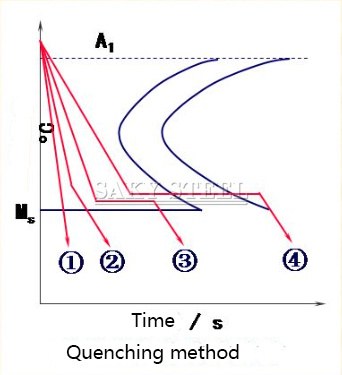

5. Izindlela zokucisha kanye nezimpawu zazo:

①Ukucisha Okulula: Kulula ukusebenza futhi kulungele izingcezu zokusebenza ezincane, ezinomumo olula. I-microstructure ewumphumela yi-martensite (M).

②Ukucisha Kabili: Okuyinkimbinkimbi kakhulu futhi okunzima ukulawula, kusetshenziselwa insimbi enomumo oyinkimbinkimbi wekhabhoni kanye nezinsimbi zokusebenza ezinkulu ze-alloy. I-microstructure ewumphumela yi-martensite (M).

③Ukucisha Okuphukile: Inqubo eyinkimbinkimbi kakhulu, esetshenziselwa izingcezu zokusebenza zensimbi yealloy enkulu, emise okuyinkimbinkimbi. I-microstructure ewumphumela yi-martensite (M).

④I-Isothermal Quenching: Isetshenziselwa izingcezu zokusebenza ezincane, eziyinkimbinkimbi ezinezidingo eziphezulu. I-microstructure ewumphumela yi-bainite ephansi (B).

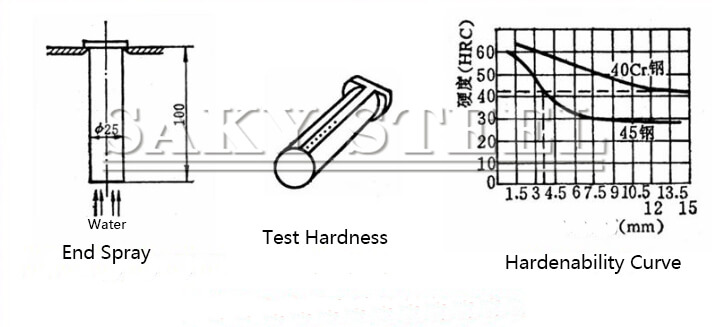

6.Izici Ezithinta Ukuqina

Izinga lokuqina lincike ekuzinzeni kwe-austenite ene-supercooled ensimbi. Ukuphakama kokuqina kwe-austenite epholile kakhulu, kuba ngcono ukuqina, futhi okuphambene nalokho.

Izinto Ezithonya Ukuzinza kwe-Supercooled Austenite:

Ukuma Kwejika-C: Uma ijika le-C lishintshela kwesokudla, izinga lokupholisa elibalulekile lokucisha liyehla, lithuthukisa ukuqina.

Isiphetho Esibalulekile:

Noma iyiphi into eshintsha ijika le-C iye kwesokudla inyusa ukuqina kwensimbi.

Isici Esiyinhloko:

Ukubunjwa Kwamakhemikhali: Ngaphandle kwe-cobalt (Co), zonke izakhi ze-alloying ezincibilikisiwe ku-austenite zandisa ukuqina.

Uma okuqukethwe kwekhabhoni kusondele ekubunjweni kwe-eutectoid ku-carbon steel, kulapho ijika le-C lishintshela kwesokudla, futhi kuba lukhuni phezulu.

7.Ukuzimisela kanye nokumelwa kokuqina

①Qeda Ukuhlolwa Kokuqina Kokucisha: Ukuqina kukalwa kusetshenziswa indlela yokuhlola yokucisha ukuphela.

②I-Critical Quench Diameter Method: I-Critical Quench Diameter (D₀) imele ububanzi obukhulu bensimbi obungaqiniswa ngokugcwele endaweni ethile yokucisha.

B.Ukushisa

1. Incazelo ye-Tempering

I-Tempering iyinqubo yokwelapha ukushisa lapho insimbi ecishiwe ishisisa kabusha ibe izinga lokushisa elingaphansi kwephoyinti elingu-A₁, eligcinwe kulelo zinga lokushisa, bese lipholiswa libe ekamelweni lokushisa.

2. Inhloso Yokuthambisa

Yehlisa noma Uqede Ukucindezelwa Okusele: Ivimbela ukuguquguquka noma ukuqhekeka kocwecwe lokusebenza.

Nciphisa noma Susa i-Residual Austenite: Iqinisa ubukhulu bocezu lokusebenza.

Khipha Ukuqina Kwensimbi Ecishiwe: Ilungisa isakhiwo esincane kanye nezakhiwo ukuze kuhlangatshezwane nezidingo zengcezu yokusebenza.

Isaziso esibalulekile: Insimbi kufanele ifuthe ngokushesha ngemva kokucisha.

3.Izinqubo Zokuthambisa

1.Low Tempering

Inhloso: Ukunciphisa ingcindezi yokuqeda ingcindezi, thuthukisa ukuqina kwe-workpiece, futhi uzuze ubulukhuni obuphezulu nokumelana nokugqoka.

Izinga lokushisa: 150°C ~ 250°C.

Ukusebenza: Ukuqina: HRC 58 ~ 64. Ukuqina okuphezulu nokumelana nokugqoka.

Izicelo: Amathuluzi, isikhunta, ama-bearings, izingxenye ze-carburized, kanye nezingxenye eziqiniswe phezulu.

2.Ukushisa okuphezulu

Inhloso: Ukuthola ukuqina okuphezulu kanye namandla anele nobulukhuni.

Izinga lokushisa: 500°C ~ 600°C.

Ukusebenza: Ukuqina: HRC 25 ~ 35. Izakhiwo ezinhle zemishini iyonke.

Izicelo: Amashafu, amagiya, izinduku zokuxhuma, njll.

Ukucwenga okushisayo

Incazelo: Ukucisha okulandelwa ukushisa okuphezulu kubizwa ngokuthi ukucwenga okushisayo, noma ukumane ukufuthelana. Insimbi ephathwa ngale nqubo inokusebenza okuhle kakhulu okuphelele futhi isetshenziswa kabanzi.

Ⅳ.Ukwelashwa Kokushisa Okungaphezulu Kwensimbi

A.Ukucinywa Kwezinsimbi

1. Incazelo Yokuqina Kobuso

Ukuqina kwendawo kuyinqubo yokwelapha ukushisa edizayinelwe ukuqinisa ungqimba olungaphezulu lwesiqeshana sokusebenza ngokusishisisa ngokushesha ukuze kuguqule ungqimba olungaphezulu lube yi-austenite bese lupholisa ngokushesha. Le nqubo yenziwa ngaphandle kokushintsha ukwakheka kwamakhemikhali ensimbi noma ukwakheka okuyinhloko kwezinto.

2. Izinto Ezisetshenziswayo Ekwenzeni Ukuqina Komhlaba kanye Nokwakheka Kwangemuva Kokuqina

Izinto Ezisetshenziselwa Ukuqinisa Ubuso

Izinto Ezivamile: Insimbi ye-carbon emaphakathi kanye nensimbi ye-carbon alloy ephakathi.

Ukwelashwa Kwangaphambili:Inqubo Ejwayelekile: I-Tempering. Uma izakhiwo eziyinhloko zingabalulekile, i-normalization ingasetshenziswa esikhundleni salokho.

Ukwakheka Kwangemuva Kokuqina

Isakhiwo Sokuphezulu: Isendlalelo esingaphezulu ngokuvamile sakha isakhiwo esiqinile njenge-martensite noma i-bainite, esihlinzeka ngobulukhuni obuphezulu nokumelana nokuguga.

Isakhiwo Esiwumgogodla: Ingqikithi yensimbi ngokuvamile igcina isakhiwo sayo sangempela, esifana ne-pearlite noma isimo esishisayo, kuye ngenqubo yokwelashwa kwangaphambili kanye nezakhiwo zezinto eziyisisekelo. Lokhu kuqinisekisa ukuthi umgogodla ugcina ukuqina okuhle namandla.

B.Izici zokuqina kwe-induction surface

I-1.Izinga Lokushisa Lokushisa Okuphezulu kanye Nokwenyuka Kwezinga Lokushisa Okusheshayo: Ukuqina kwe-induction surface ngokuvamile kuhilela izinga lokushisa eliphezulu lokushisa kanye namazinga okushisa asheshayo, okuvumela ukushisa okusheshayo phakathi nesikhathi esifushane.

I-2.I-Fine Austenite Grain Structure ku-Surface Layer: Ngesikhathi sokushisisa okusheshayo nenqubo yokucisha elandelayo, ungqimba olungaphezulu lwakha okusanhlamvu okuhle kwe-austenite. Ngemva kokucisha, indawo engaphezulu ngokuyinhloko iqukethe i-martensite ecolekile, ngobulukhuni ngokuvamile obungu-2-3 HRC ngaphezu kokucisha okuvamile.

3.Ikhwalithi Enhle Yobuso: Ngenxa yesikhathi esifushane sokushisisa, indawo yokusebenza ayithambekele kangako ekufakweni kwe-oxidation kanye ne-decarburization, futhi ukuwohloka okubangelwa ukucisha kuyancishiswa, okuqinisekisa ikhwalithi enhle yendawo.

I-4.Amandla Okukhathala Okuphezulu: Ukuguqulwa kwesigaba se-martensitic kungqimba olungaphezulu kukhiqiza ukucindezeleka okucindezelayo, okwandisa amandla okukhathala komsebenzi.

I-5.Ukusebenza Okuphezulu Kokukhiqiza: Ukuqina kwe-induction surface kulungele ukukhiqizwa ngobuningi, okunikeza ukusebenza kahle okuphezulu.

C.Ukuhlelwa kokwelashwa kokushisa kwamakhemikhali

Carburizing,Carburizing,Carburizing,Chromizing,Siliconizing,Siliconizing,Siliconizing,Carbonitriding,Borocarburizing

I-D.Gas Carburizing

I-Gas Carburizing iyinqubo lapho ucezu lokusebenza lufakwa esithandweni somlilo esivalekile segesi futhi sishiselwe ezingeni lokushisa eliguqula insimbi ibe yi-austenite. Ngemuva kwalokho, i-ejenti yokungcwatshwa kwe-carburizing idonselwa esithandweni, noma kwethulwa umoya wokungcwaba ngokuqondile, okuvumela ama-athomu ekhabhoni ukuthi asakazeke ongqimbeni olungaphezulu lwesiqeshana sokusebenza. Le nqubo inyusa okuqukethwe kwekhabhoni (wc%) endaweni yokusebenza.

√Abenzeli beCarburizing:

•Amagesi anothe ngekhabhoni: Njengegesi yamalahle, i-liquefied petroleum gas (LPG), njll.

•Uketshezi Lwemvelo: Okufana nophalafini, i-methanol, i-benzene, njll.

√Amapharamitha wenqubo yeCarburizing:

•I-Carburizing Temperature: 920~950°C.

•Isikhathi Sokungcwatshwa: Kuncike ekujuleni okufiswayo kwesendlalelo se-carburized kanye nezinga lokushisa le-carburizing.

E. Ukwelashwa Kokushisa Ngemva Kokungcwatshwa Kwe-Carburizing

Insimbi kufanele iphathwe ngokushisa ngemuva kokungcwatshwa kwe-carburizing.

Inqubo Yokwelapha Ukushisa Ngemva Kwe-Carburizing:

√Ukucisha + Ukushisa Kwezinga Eliphansi

1.Ukucisha Okuqondile Ngemva Kokupholisa Kwangaphambi Kokupholisa + Ukushisa Okuphansi Kwezinga Lokushisa: Indawo yokusebenza ipholiswa kusengaphambili ukusuka kuzinga lokushisa le-carburizing ukuya ngaphezu nje kwezinga lokushisa eliwumgogodla we-Ar₁ bese icinywa ngokushesha, kulandelwa izinga lokushisa eliphansi ku-160~180°C.

2.Ukucisha Okukodwa Ngemva Kokupholisa Kwangaphambi Kokupholisa + Ukushisa Kwezinga Eliphansi: Ngemva kokungcwatshwa kwe-carburizing, ucezu lokusebenza lupholiswa kancane kancane ukuze lube kuzinga lokushisa elilingana negumbi, bese lushiselwa kabusha ukuze lucime kanye nezinga lokushisa eliphansi.

3.Ukucisha Kabili Ngemva Kokupholisa Kwangaphambi Kokupholisa + Ukushisa Okuphansi Kwezinga lokushisa: Ngemva kokungcwatshwa kwe-carburizing nokupholisa kancane, ucezu lomsebenzi lungena ezigabeni ezimbili zokushisisa nokucisha, okulandelwa ukushisa okuphansi.

Ⅴ.Ukwelashwa Kokushisa Kwekhemikhali Kwezinsimbi

I-1.Incazelo Yokwelashwa Kokushisa Kwamakhemikhali

Ukwelashwa kokushisa ngamakhemikhali kuyinqubo yokwelapha ukushisa lapho ucwecwe lwensimbi lufakwa endaweni ethile esebenzayo, lushisiwe, futhi lubanjwe ezingeni lokushisa, okuvumela ama-athomu asebenzayo aphakathi nendawo ukuthi asakazeke ebusweni bomsebenzi. Lokhu kushintsha ukwakheka kwamakhemikhali kanye ne-microstructure yendawo yokusebenza, ngaleyo ndlela iguqule izici zayo.

I-2.Inqubo Eyisisekelo Yokwelashwa Kokushisa Kwamakhemikhali

Ukubola: Ngesikhathi sokushisa, i-medium esebenzayo iyabola, ikhiphe ama-athomu asebenzayo.

Ukumuncwa: Ama-athomu asebenzayo akhangwa ngobuphezulu bensimbi futhi ancibilike abe yisixazululo esiqinile sensimbi.

Ukusabalalisa: Ama-athomu asebenzayo amuncwa futhi ancibilike ebusweni bensimbi athuthela ngaphakathi.

Izinhlobo Zokuqiniswa Kwendawo Yokungeniswa

a.High-Frequency Induction Heating

Imvamisa yamanje: 250~300 kHz.

Ukujula Kwesendlalelo Esiqinile: 0.5~2.0 mm.

Izicelo: Amagiya amamojula amaphakathi namancane kanye namashafu amancane kuya kosayizi omaphakathi.

b.Medium-Frequency Induction Heating

Imvamisa yamanje: 2500~8000 kHz.

Ukujula Kwesendlalelo Esiqinile: 2~10 mm.

Izinhlelo zokusebenza: Amashafti amakhulu namagiya amamojula amakhulu ukuya kwaphakathi.

c.Power-Frequency Induction Heating

Imvamisa yamanje: 50 Hz.

Ukujula Kwesendlalelo Esiqinile: 10~15 mm.

Izinhlelo zokusebenza: Izinto zokusebenza ezidinga isendlalelo esiqinile esijulile.

3. Ukuqina kwe-Surface yokungeniswa

Umgomo Oyisisekelo Wokuqiniswa Kwendawo Yokungeniswa

Umphumela Wesikhumba:

Lapho ukushintshana kwamanje kukhoyili yokungeniswa kubangela i-current ebusweni bomsebenzi, iningi lamanje elingeniswayo ligxiliswa eduze nendawo, kuyilapho cishe akukho okwamanje okudlula ngaphakathi kwendawo yokusebenza. Lesi simo saziwa ngokuthi umphumela wesikhumba.

Umgomo Wokuqiniswa Kwendawo Yokungeniswa:

Ngokusekelwe kumphumela wesikhumba, ubuso be-workpiece bushiswa ngokushesha ekushiseni kwe-austenitizing (kukhuphukela ku-800 ~ 1000 ° C ngemizuzwana embalwa), kuyilapho ingaphakathi le-workpiece lihlala licishe lingashisi. I-workpiece bese ipholiswa ngokufafaza ngamanzi, ukufeza ukuqina kwendawo.

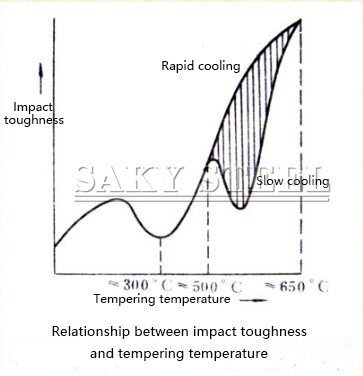

4.I-Temper Brittleness

I-Tempering Brittleness Ensimbi Ecinyiwe

I-Tempering brittleness ibhekisela kwinto lapho ukuqina komthelela wensimbi ecishiwe kwehla kakhulu lapho kushiswe kumazinga okushisa athile.

Uhlobo Lokuqala Lwe-Tempering Brittleness

Ibanga lokushisa: 250°C kuya ku-350°C.

Izici: Uma insimbi ecishiwe iqiniswa ngaphakathi kwalolu banga lokushisa, maningi amathuba okuthi kuthuthukiswe lolu hlobo lwe- tempering brittleness, olungakwazi ukuqedwa.

Isixazululo: Gwema ukuthulisa insimbi ecishiwe ngaphakathi kwalolu banga lokushisa.

Uhlobo lokuqala lokufutheka kolaka lwaziwa nangokuthi i-low-temperature brittleness noma ukufutheka okungenakulungiseka.

Ⅵ.Ukushisa

I-1.I-Tempering iyinqubo yokugcina yokwelapha ukushisa elandela ukucisha.

Kungani Izinsimbi Ezicishiwe Zidinga Ukushisa?

I-Microstructure Ngemva Kokucisha:Ngemva kokucisha, i-microstructure yensimbi ngokuvamile iqukethe i-martensite ne-austenite esele. Zombili ziyizigaba ze-metastable futhi zizoshintsha ngaphansi kwezimo ezithile.

Izakhiwo ze-Martensite:I-Martensite ibonakala ngobulukhuni obuphezulu kodwa futhi nokuba nokuqina okuphezulu (ikakhulukazi ku-high-carbon-like-like martensite), engahlangabezani nezimfuneko zokusebenza zezinhlelo eziningi zokusebenza.

Izici Zokuguqulwa Kwe-Martensitic: Ukuguqulwa ku-martensite kwenzeka ngokushesha okukhulu. Ngemva kokucisha, i-workpiece inezingcindezi zangaphakathi ezisele ezingaholela ekuguquguqukeni noma ekuqhekekeni.

Isiphetho:I-workpiece ayikwazi ukusetshenziswa ngqo ngemuva kokucisha! Ukushisa kuyadingeka ukuze kuncishiswe izingcindezi zangaphakathi futhi kuthuthukiswe ukuqina kwe-workpiece, okwenza ifanelekele ukusetshenziswa.

2.Umehluko Phakathi Kokuqina Nokuqina Kokuqina:

Ukuqina :

Ukuqina kubhekisela ekhonweni lensimbi lokufeza ukujula okuthile kokuqina (ukujula kongqimba oluqinile) ngemva kokucisha. Kuncike ekubunjweni nasekubunjweni kwensimbi, ikakhulukazi izakhi zayo ze-alloying kanye nohlobo lwensimbi. Ukuqina kuyisilinganiso sokuthi insimbi ingaba lukhuni kangakanani phakathi nokuqina kwayo phakathi nenqubo yokucisha.

Ukuqina (Amandla Aqinisayo):

Ukuqina, noma ukuqina kwamandla, kubhekisela ebukhuni obukhulu obungafinyelelwa ensimbi ngemva kokucisha. Ithonywa kakhulu yi-carbon content yensimbi. Okuqukethwe kwekhabhoni ephezulu ngokuvamile kuholela ebukhuni obunamandla obuphezulu, kodwa lokhu kungakhawulwa izakhi zensimbi ezihlanganisiwe nokusebenza ngempumelelo kwenqubo yokucisha.

3.Ukuqina Kwensimbi

√Umqondo wokuqina

Ukuqina kubhekisela ekhonweni lensimbi lokufinyelela ukujula okuthile kokuqina kwe-martensitic ngemva kokucisha izinga lokushisa le-austenitizing. Ngamagama alula, kuyikhono lensimbi ukwenza i-martensite ngesikhathi sokucisha.

Ukulinganisa Ukuqina

Ubukhulu bokuqina buboniswa ukujula kwesendlalelo esiqinile esitholakala ngaphansi kwezimo ezicacisiwe ngemva kokucisha.

Ukujula Kwesendlalelo Esiqinile: Lokhu ukujula okuvela ebusweni bomsebenzi kuya endaweni lapho isakhiwo siyingxenye ye-martensite.

Imidiya Ejwayelekile Yokucima:

•Amanzi

Izici: Inomnotho inamandla okupholisa aqinile, kodwa inezinga lokupholisa eliphezulu eduze nendawo yokubilisa, okungaholela ekupholiseni ngokweqile.

Isicelo: Ngokuvamile esetshenziselwa carbon steels.

Amanzi Asawoti: Isixazululo sikasawoti noma i-alkali emanzini, esinamandla okupholisa aphezulu emazingeni okushisa aphezulu uma kuqhathaniswa namanzi, okwenza afanelekele izinsimbi zekhabhoni.

•Amafutha

Izici: Ihlinzeka ngezinga lokupholisa elihamba kancane emazingeni okushisa aphansi (eduze kwendawo yokubilisa), okunciphisa ngempumelelo ukuthambekela kokuguquguquka nokuqhekeka, kodwa okunamandla okupholisa aphansi emazingeni okushisa aphezulu.

Isicelo: Ifanele izinsimbi ze-alloy.

Izinhlobo: Kufaka uwoyela wokucisha, uwoyela womshini, nophethiloli wedizili.

Isikhathi Sokushisa

Isikhathi sokushisa sihlanganisa kokubili izinga lokushisa (isikhathi esithathwa ukuze kufinyelelwe izinga lokushisa elifunekayo) kanye nesikhathi sokubamba (isikhathi esigcinwe ezingeni lokushisa eliqondiwe).

Izimiso Zokunquma Isikhathi Sokushisa:Qinisekisa ukusatshalaliswa kwezinga lokushisa okufanayo kulo lonke ucezu lokusebenza, ngaphakathi nangaphandle.

Qinisekisa ukuthi i-austenitization ephelele nokuthi i-austenite eyenziwe ifana futhi ilungile.

Isisekelo Sokunquma Isikhathi Sokushisa:Imvamisa kulinganiselwa kusetshenziswa amafomula e-empirical noma kunqunywa ngokuhlolwa.

Ukucisha Imidiya

Izici Ezimbili Eziyinhloko:

a.Izinga Lokupholisa: Izinga lokupholisa eliphezulu likhuthaza ukwakheka kwe-martensite.

b.I-Residual Stress: Izinga lokupholisa eliphakeme linyusa ukucindezeleka kwensalela, okungaholela ekuthambekeleni okukhulu kokuguquguquka nokuqhekeka kucezu lokusebenza.

Ⅶ.Ukujwayela

1. Incazelo ye-Normalizing

Ukwenza okujwayelekile kuyinqubo yokwelapha ukushisa lapho insimbi ishiselwa kuzinga lokushisa elingu-30°C kuya ku-50°C ngaphezu kwezinga lokushisa le-Ac3, eligcinwe kulelo zinga lokushisa, bese lipholiswa ngomoya ukuze lithole i-microstructure eseduze nesimo sokulingana. Uma kuqhathaniswa ne-annealing, ukujwayela kunezinga lokupholisa elisheshayo, okuholela ekwakhekeni kwe-pearlite ecolekile (P) namandla aphezulu nobulukhuni.

2. Inhloso Yokujwayela

Inhloso yokwenza i-normalization ifana neye-annealing.

3. Izicelo Zokujwayela

•Susa usimende wesibili wenethiwekhi.

•Khonza njengokwelashwa kokugcina kokushisa kwezingxenye ezinezidingo eziphansi.

•Yenza njengendlela yokwelapha yokushisa elungiselela insimbi yesakhiwo sekhabhoni ephansi naphakathi ukuze uthuthukise ukusebenza kahle.

4.Izinhlobo ze-Annealing

Uhlobo Lokuqala Lokuhlanganisa:

Inhloso Nomsebenzi: Umgomo awukona ukunxenxa ukuguqulwa kwesigaba kodwa ukuguqula insimbi isuke esimweni esingalingani iye esimweni esilinganiselwe.

Izinhlobo:

•I-Diffusion Annealing: Ihlose ukwenza i-homogenize ukwakheka ngokususa ukuhlukaniswa.

•Recrystallization Annealing: Ibuyisela i-ductility ngokususa imiphumela yokuqina komsebenzi.

•I-Stress Relief Annealing: Yehlisa ukucindezeleka kwangaphakathi ngaphandle kokushintsha i-microstructure.

Uhlobo Lwesibili Lokuhlanganisa:

Inhloso Nomsebenzi: Ihlose ukuguqula i-microstructure kanye nezakhiwo, kuzuzwe i-microstructure elawulwa yi-pearlite. Lolu hlobo luphinde luqinisekise ukuthi ukusatshalaliswa kanye ne-morphology ye-pearlite, i-ferrite, ne-carbides ihlangabezana nezidingo ezithile.

Izinhlobo:

•I-Annealing Egcwele: Ishisisa insimbi ngaphezu kwezinga lokushisa le-Ac3 bese ipholisa kancane ukuze ikhiqize ukwakheka okufanayo kwe-pearlite.

•I-Annealing Engaphelele: Ishisisa insimbi phakathi kwamazinga okushisa e-Ac1 ne-Ac3 ukuze kuguqulwe ingxenye yesakhiwo.

•I-Isothermal Annealing: Ishisisa insimbi ibe ngaphezu kwe-Ac3, okulandelwa ukupholisa okusheshayo kumazinga okushisa e-isothermal nokubamba ukuze kuzuzwe isakhiwo esifunekayo.

•I-Spheroidizing Annealing: Ikhiqiza ukwakheka kwe-spheroidal carbide, ithuthukisa ukusebenza kahle nokuqina.

Ⅷ.1.Incazelo Yokwelashwa Kokushisa

Ukwelashwa kokushisa kubhekisela enqubweni lapho insimbi ishiswa khona, ibanjwe ezingeni lokushisa elithile, bese ipholiswa ngenkathi isesimweni esiqinile ukuze kuguqulwe isakhiwo sayo sangaphakathi kanye nesakhiwo esincane, ngaleyo ndlela kuzuzwe izici ezifiselekayo.

2.Izici Zokwelashwa Kokushisa

Ukwelashwa kokushisa akushintshi isimo se-workpiece; esikhundleni salokho, ishintsha isakhiwo sangaphakathi kanye ne-microstructure yensimbi, ebuye iguqule izakhiwo zensimbi.

3.Inhloso Yokwelashwa Kokushisa

Inhloso yokwelashwa kokushisa ukuthuthukisa izakhi zensimbi noma zokucubungula zensimbi (noma izingcezu zokusebenza), ukusebenzisa ngokugcwele amandla ensimbi, ukuthuthukisa ikhwalithi yendawo yokusebenza, nokwelula impilo yayo yesevisi.

4. Isiphetho Esiyinhloko

Ukuthi izici zezinto ezibonakalayo zingathuthukiswa yini ngokwelashwa kokushisa kuncike kakhulu ekutheni zikhona yini izinguquko ku-microstructure yayo kanye nesakhiwo phakathi nenqubo yokushisisa nokupholisa.

Isikhathi sokuthumela: Aug-19-2024