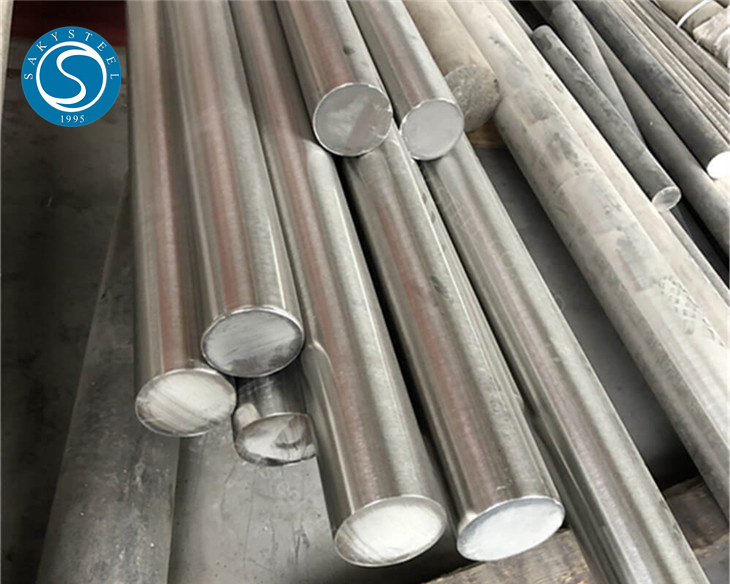

EN 1.4913 (X19CrMoNbVN11-1) Ibha Yensimbi Engagqwali

Incazelo emfushane:

I-TS EN 1.4913 (X19CrMoNbVN11-1) Ibha Yensimbi Engagqwali iyingxubevange esebenza kahle edizayinelwe izinhlelo zokusebenza endaweni enezinga lokushisa eliphezulu.

EN 1.4913 Ibha Yensimbi Engagqwali:

I-EN 1.4913 (X19CrMoNbVN11-1) ibha yensimbi engagqwali iyingxubevange esebenza kahle edizayinelwe izinhlelo zokusebenza endaweni enezinga lokushisa eliphezulu. Ihlanganiswe ne-chromium, i-molybdenum, i-niobium, ne-vanadium, inikeza ukumelana okuhle kakhulu kwe-oxidation, amandla okukhasa, nokuqina kwesikhathi eside. Lokhu okubalulekile kulungele izimboni ezifana nokukhiqiza amandla, ukucutshungulwa kwamakhemikhali, kanye ne-aerospace, lapho amandla aphezulu, ukumelana nokushisa, kanye nezakhiwo ezimelana nokugqwala zibalulekile. Ukuzinza kwayo okushisayo kuyenza ifaneleke ukusetshenziswa ezintweni ezinjengamabhayela, izishintshisi zokushisa, nama-turbines, lapho ukusebenza ngaphansi kwezimo ezimbi kakhulu kubalulekile.

Imininingwane Yebha yensimbi ye-X19CrMoNbVN11-1:

| Imininingwane | I-EN 10269 |

| Ibanga | 1.4913 ,X19CrMoNbVN11-1 |

| Ubude | 1-12M & Ubude obudingekayo |

| I-Surface Qeda | Emnyama, Ekhanyayo |

| Ifomu | Umjikelezo |

| Qeda | I-Plain End, I-Beveled End |

| Isitifiketi Sokuhlolwa Kwemishini | EN 10204 3.1 noma EN 10204 3.2 |

Ibha yensimbi engagqwali ye-1.4913 Ukwakheka Kwamakhemikhali:

| Ibanga | C | Mn | P | S | Cr | Ni | Mo | Al | V |

| 1.4913 | 0.17-0.23 | 0.4-0.9 | 0.025 | 0.015 | 10.0-11.5 | 0.20-0.60 | 0.5-0.8 | 0.02 | 0.1-0.3 |

I-EN 1.4913 ibha yensimbi engenasici iphathwa kanjani ngokushisa?

Inqubo yokwelapha ukushisa ye-EN 1.4913 (X19CrMoNbVN11-1) ibha yensimbi engagqwali ihlanganisa ukuvala isixazululo, ukukhulula ingcindezi, nokuguga. Ukukhishwa kwesixazululo ngokuvamile kwenziwa phakathi kuka-1050°C no-1100°C ukuze kuhlanganiswe isakhiwo nokuncibilikisa ama-carbides, okulandelwa ukupholisa ngokushesha. Ukudambisa ingcindezi kwenziwa ku-600°C kuya ku-700°C ukuze kususwe izingcindezi ezisalela kumishini noma ekushiseleni. Ukuguga kwenziwa ku-700°C kuya ku-750°C ukuze kuthuthukiswe amandla nokumelana nokukhasa. Lezi zinyathelo zokwelashwa kokushisa zithuthukisa ukumelana ne-oxidation yezinga eliphezulu lokushisa, amandla emishini, nokumelana nokunyakaza, kuyenze ifanelekele izicelo ezidinga izinga lokushisa eliphezulu.

Izicelo ze-EN 1.4913 ibha yensimbi engagqwali?

I-EN 1.4913 (X19CrMoNbVN11-1) ibha yensimbi engagqwali isetshenziswa kakhulukazi ekusetshenzisweni kwezinga lokushisa okuphezulu kanye nengcindezi ephezulu lapho kudingeka khona amandla akhethekile, ukumelana ne-oxidation, nokuqina kwesikhathi eside. Ezinye zezinhlelo zokusebenza eziyinhloko zihlanganisa:

1.Ukukhiqiza Amandla: Kusetshenziswa ezitshalweni zikagesi, ikakhulukazi kumaturbine esitimu, amabhayela, nezishintshisi zokushisa, lapho ukumelana nezinga lokushisa eliphezulu nokugqwala kubalulekile.

2.I-Aerospace: Iqashwe kuma-turbine blades, izingxenye zenjini, nezinye izingxenye ezinezinga eliphezulu lokushisa okufanele zimelane nokushisa okukhulu nokucindezela embonini ye-aerospace.

3.Ukucutshungulwa Kwamakhemikhali:Kusetshenziswa kuma-reactors amakhemikhali, izishintshisi zokushisa, nezinye izinto zokusebenza ezichayeka endaweni egqwalayo namazinga okushisa aphezulu.

4.Imboni ye-Petrochemical: Ilungele izingxenye zezitshalo ze-petrochemical, ezifana nama-reactor namasistimu amapayipi, asebenza ngaphansi kwengcindezi ephezulu yokushisa kanye nemishini.

I-5.Amafutha Negesi: Isetshenziswa ekubhoboleni nasekucwengisiseni imishini lapho amandla okushisa aphezulu kanye nokumelana ne-oxidation nokugqwala kubalulekile ekusebenzeni isikhathi eside.

6.Izingxenye Zokubhoyisa: Zisetshenziswa ekwenzeni amashubhu okubhayela, amashubhu okushisa okuphezulu, nezinye izingxenye ezibalulekile ezivezwe endaweni enezinga eliphezulu lokushisa.

7.Izishintshi Zokushisa:Kuqashwe kumashubhu okushintsha ukushisa kanye nezingxenye ngenxa yekhono layo lokumelana nokuhamba ngebhayisikili okushisayo kanye nokugqwala kwezinga eliphezulu lokushisa.

1.4913 (X19CrMoNbVN11-1) Ibha Izimpawu Zokhiye

I-EN 1.4913 (X19CrMoNbVN11-1) ingxubevange yensimbi engagqwali esebenza kahle kakhulu edizayinelwe izinga lokushisa eliphezulu kanye nokufakwa kwengcindezi ephezulu, ikakhulukazi ezimbonini eziphehla ugesi kanye nezimboni ze-petrochemical. Nazi izici ezibalulekile zale nto:

1. Ukumelana Nokushisa Okuphezulu:Ibanga Lezinga lokushisa: I-EN 1.4913 yakhelwe ngokukhethekile ukuthi imelane namazinga okushisa aphakeme, iyenze ifaneleke ukusetshenziswa ezitshalweni zikagesi, izinjini zesitimu, nezinye izindawo ezishisa kakhulu.

2. Ukumelana Nokugqwala Okuhle Kakhulu

I-Oxidation Resistance: Inikeza ukumelana okuhle ne-oxidation, iyenze ifanelekele ukusetshenziswa ezindaweni ezinokhahlo ezinamazinga okushisa aphezulu kanye nemidiya enolaka.

3. Amandla Amahle Nokuqina:Amandla Aphezulu: I-EN 1.4913 inikeza amandla amahle emazingeni okushisa aphezulu futhi igcina izakhiwo zayo zemishini ngisho nangaphansi kwengcindezi nemithwalo ephezulu.

4. Ukwakheka Kwengxubevange:Izinto Eziyinhloko: Ingxubevange iqukethe i-Chromium (Cr), i-Molybdenum (Mo), i-Niobium (Nb), ne-Vanadium (V), ethuthukisa amandla ayo kanye nokumelana nokukhuphuka kwezinga lokushisa eliphezulu. Lokhu kuyenza ifanelekele ukuchayeka isikhathi eside ezindaweni ezinezinga lokushisa eliphezulu.

5. Ukushisela Okuhle Nokwakheka: Ukushisela: I-EN 1.4913 ingashiswa kusetshenziswa izindlela ezivamile ezifana ne-TIG, i-MIG, ne-coated electrode welding, nakuba ukushisa kwangaphambi kwesikhathi kungase kudingeke ukuze kugwenywe ukwakheka kwezigaba eziphukayo.

6. I-Creep Resistance: Ingxubevange ikhombisa ukumelana nokunyakaza okuhle kakhulu, okusho ukuthi igcina amandla ayo esikhathini eside sokuchayeka kumazinga okushisa aphezulu nengcindezi, okubalulekile ekusetshenzisweni kwamandla nasekuphehleni amandla.

7. Ukumelana Nokukhathala:Inokumelana nokukhathala okuhle, okusho ukuthi ingakwazi ukumelana nemijikelezo yokulayisha ephindaphindiwe, okubalulekile ezingxenyeni ezingaphansi kwezimo zengcindezi ezishintshashintshayo.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS, TUV, BV 3.2.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Ukupakisha Amabha Ensimbi Engagqwali:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,