I-DIN 1.2367 Insimbi Yensimbi

Incazelo emfushane:

Insimbi ye-DIN 1.2367, enye ebizwa ngokuthi i-X38CrMoV5-3, igqama njengensimbi yethuluzi lomsebenzi oshisayo elaziwa ngokuqina kwayo okumangalisayo, amandla aphakeme emazingeni okushisa aphezulu, kanye nokumelana okuvelele ekuqhekekeni okubangelwa ukushisa.

I-DIN 1.2367 Insimbi Yensimbi:

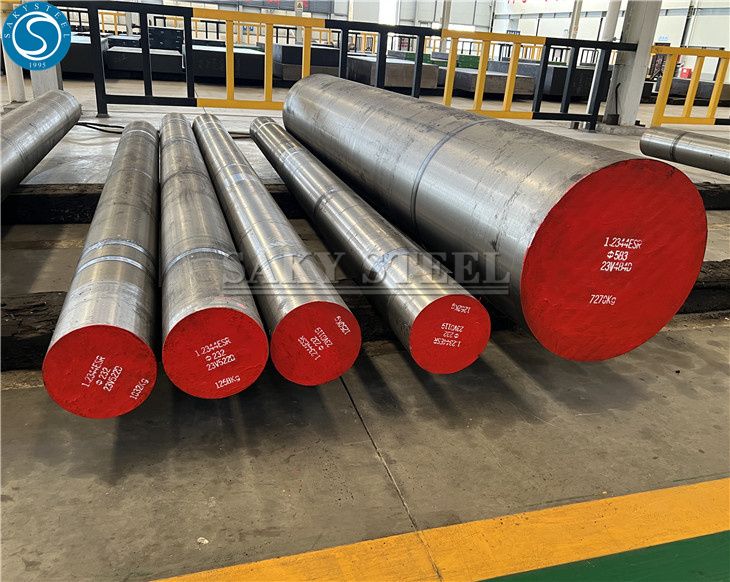

Ibha yensimbi engu-1.2367, eyaziwa nangokuthi i-X38CrMoV5-3, iwuhlobo lwensimbi yensimbi yomsebenzi oshisayo ebonakala ngokuqina okukhethekile, amandla aphezulu okushisa, nokumelana nokuhlola ukushisa. Le bha yensimbi ilungele izinhlelo zokusebenza ezihlukene zezimboni ezihlanganisa ukwenza isikhunta, i-die casting, i-extrusion, kanye ne-forging. Izakhiwo zayo ezivelele ziyenza ibe into ethandwayo yokuphatha izinga lokushisa eliphezulu kanye nezindawo ezinengcindezi ephezulu.

Imininingwane ye-DIN 1.2367 Steel:

| Ibanga | 1.2367 |

| Okujwayelekile | I-EN ISO 4957 |

| Ubuso | Emnyama, Eqinile, Ephendukile |

| Ubude | 1 kuya ku-6 Amamitha |

| Iyacubungula | Ebandayo Edwetshiwe & Epholishiwe Ebandayo Edwetshiwe, I-Centerless Ground & Epholishiwe |

| I-Raw Materail | I-POSCO, i-Baosteel, i-TISCO, i-Saky Steel, i-Outokumpu |

I-DIN 1.2376 Okulingana nensimbi:

| Okujwayelekile | I-EN ISO 4957 | AISI | I-JIS | I-GOST |

| Ibanga | I-X38CrMoV5-3 | AISI H11 | SKD6 | 4Ch5MFS |

Ukwakhiwa Kwekhemikhali Kwensimbi Yensimbi engu-1.2367:

| Ibanga | C | Mo | V | Si | Cr |

| ISO 4957 1.2367/X38CrMoV5-3 | 0.38-0.40 | 2.70-3.20 | 0.40-0.60 | 0.30-0,50 | 4.80-5.20 |

| AISI H11 | 0.35-0.45 | 1.1-1.6 | 0.3-0.6 | 0.8-1.25 | 4.75-5.5 |

| I-JIS SKD6 | 0.32-0.42 | 1.0-1.5 | 0.3-0.5 | 0.8-1.2 | 4.5-5.5 |

| I-GOST 4Ch5MFS | 0.35-0.40 | 2.5-3.0 | 0.3-0.6 | 0.3-0.6 | 4.8-5.3 |

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Ukupakisha:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,