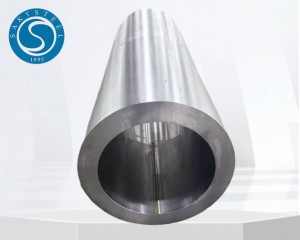

I-DIN 1.2311 P20 Mold Steel

Incazelo emfushane:

I-DIN 1.2311″ iwuhlobo olujwayelekile lwensimbi yokubumba, evame ukubizwa ngokuthi insimbi ye-P20. I-P20 iyinsimbi yokubumba enengxubevange ephansi eyaziwa ngokusebenza kahle kwayo kanye nokumelana nokugqokwa, evame ukusetshenziswa ekukhiqizeni isikhunta sepulasitiki kanye nesikhunta se-die-casting.

I-DIN 1.2311 P20 Mold Steel:

I-DIN 1.2311 P20 Mold Steel iyinsimbi yokubumba evame ukusetshenziswa, esetshenziswa kakhulu ekwenzeni isikhunta sepulasitiki kanye nezibungu ezifayo.I-DIN 1.2311 P20 Mold Steel inokusebenza okuhle kakhulu kokusika kanye nobuqili, okwenza kube lula ukucubungula kube yizimo ezihlukahlukene zokubunjwa.Ngemva kokwelashwa okufanelekile kokushisa, i-DIN1ness Steel engu-20 ingakwazi ukugqoka ukumelana nokuqina okuphezulu kwe-Mo3 i-Mold 12. ifanele ukukhiqiza isikhunta esinezidingo eziphezulu.DIN 1.2311 P20 Mold Steel ivame ukusetshenziswa ekusetshenzisweni kwesikhunta okuhlukahlukene njengesikhunta somjovo, isikhunta se-extrusion, isikhunta se-die-casting, nezisekelo zesikhunta.

Imininingwane Yezinsimbi ZETHULUSI 1.2311:

| Ibanga | 1.2311,P20 |

| Okujwayelekile | I-ASTM A681 |

| Ubuso | Mnyama; Ihlutshiwe; Ipholishiwe; Okwenziwe ngomshini; Kugaywe; Iphendukile; Igayiwe |

| I-Raw Materail | I-POSCO, i-Baosteel, i-TISCO, i-Saky Steel, i-Outokumpu |

1.2311 Amabanga Ensimbi Elinganayo:

| Izwe | USA | IsiJalimane | I-GB/T |

| Okujwayelekile | I-ASTM A681 | I-DIN EN ISO 4957 | I-GB/T 1299 |

| Amabanga | P20 | 1.2311 | 3Cr2Mo |

I-P20 Tool Steel Ukwakheka Kwekhemikhali:

| Okujwayelekile | Ibanga | C | Si | Mn | P | S | Cr | Mo |

| I-ASTM A681 | P20 | 0.28-0.40 | 0.2-0.8 | 0.60-1.0 | ≤0.030 | ≤0.030 | 1.4-2.0 | 0.3–0.55 |

| I-GB/T 9943 | 3Cr2Mo | 0.28-0.40 | 0.2-0.8 | 0.60-1.0 | ≤0.030 | ≤0.030 | 1.4-2.0 | 0.3–0.55 |

| I-DIN ISO4957 | 1.2311 | 0.35-0.45 | 0.2-0.4 | 1.3-1.6 | ≤0.030 | ≤0.030 | 1.8-2.1 | 0.15-0.25 |

1.2311 Tools Steels Mechanical Properties:

| Izakhiwo | Imethrikhi |

| Ukuqina, i-Brinell (Okuvamile) | 300 |

| Ukuqina, i-Rockwell C (Okuvamile) | 30 |

| Amandla Aqinile, Okugcina | 965-1030 MPa |

| Amandla Aqinile, Yield | 827-862 MPa |

| I-Elongation At Break (Ku-50 Mm (2″) | 20.00% |

| Amandla Acindezelayo | 862 MPa |

| I-Charpy Impact (V-Notch) | 27.1-33.9 J |

| Isilinganiso sikaPoisson | 0.27-0.30 |

| I-Elastic Modulus | 190-210 GPA |

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi yokuma okukodwa.

Izinkonzo Zethu

1.Ukucisha nokuthulisa

2.Vacuum ukwelapha ukushisa

3.Indawo epholishwe ngesibuko

4.Ukuqeda okugayiwe ngokunembe

4.CNC imishini

5.Ukubhola okunembayo

6.Sika ube yiziqephu ezincane

7.Finyelela ukunemba okufana nesikhunta

Ukupakisha:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,