422 Ibha Eyindilinga Yensimbi Engagqwali

Incazelo emfushane:

I-422 Stainless Steel iyinsimbi eqinile ye-martensitic edizayinelwe amazinga okushisa esevisi afinyelela ku-1200°F.

Ibha eyindilinga ye-UT Inspection Automatic 422:

Uma kuziwa efomini lebha eyindilinga, ivamise ukusetshenziswa ezinhlelweni lapho amandla aphezulu kanye nokumelana nokugqwala okuhle kuyadingeka. Ikhono layo lokumelana namazinga okushisa aphakeme liyenza ifanelekele ukusetshenziswa ezindaweni lapho ezinye izinsimbi bezingeke zisebenze kahle.Ifomu eliyindilinga lebha ye-422 Stainless Steel isetshenziselwa izinjongo ezihlukahlukene, okuhlanganisa ama-shaft, ama-ekseli, amagiya, nezinye izingxenye ezidinga amandla aphezulu kanye nokumelana nokugqwala. Kubalulekile ukuqinisekisa ukuthi imininingwane yebha eyindilinga ihlangabezana nezindinganiso ezidingekayo zohlelo lwakho lokusebenza oluthile.

Imininingwane yebha yensimbi engagqwali engu-422:

| Ibanga | 422 |

| Imininingwane | I-ASTM A276 |

| Ubude | 2.5M, 3M, 6M & Ubude obudingekayo |

| Ububanzi | 4.00 mm kuya ku-500 mm |

| phezulu | Bright, Black, Polish |

| Uhlobo | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| I-Raw Materail | I-POSCO, i-Baosteel, i-TISCO, i-Saky Steel, i-Outokumpu |

422 Ibha Eyindilinga Amabanga alinganayo:

| Okujwayelekile | I-UNS | Werkstoff Nr. |

| 422 | S42200 | 1.4935 |

I-422 Bar Chemical Composition:

| Ibanga | C | Si | Mn | S | P | Cr | Mo | Ni | V | Cu |

| 422 | 0.20 - 0.25 | 0.2-0.6 | ≤1.0 | ≤0.030 | ≤0.040 | 11.00-13.50 | 0.75-1.25 | 0.5-1.0 | 0.17-0.30 | 0.50 |

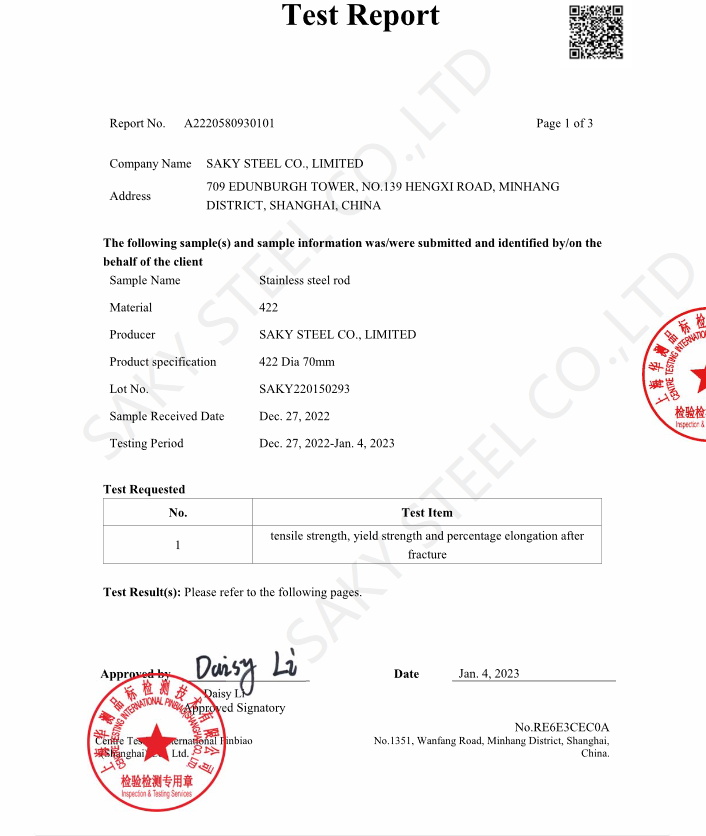

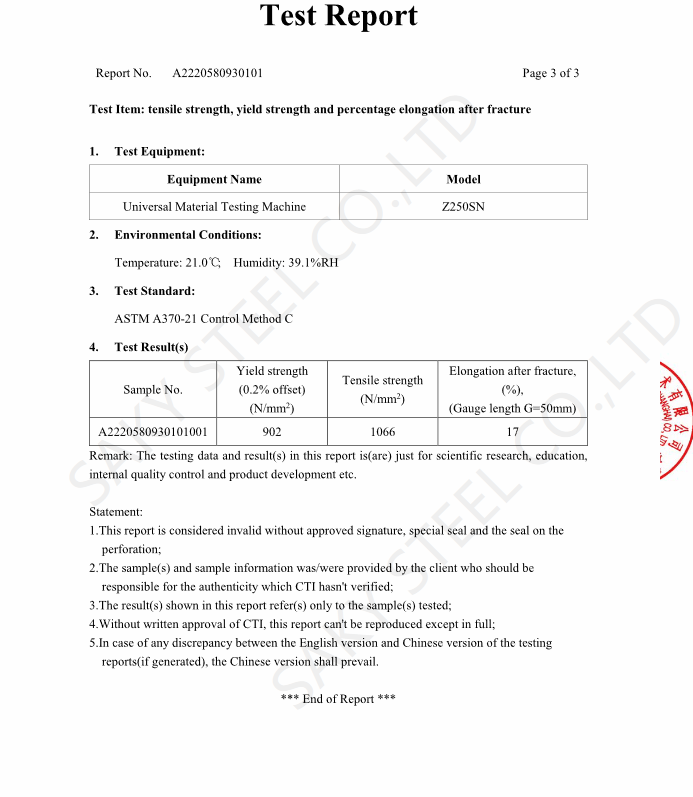

422 Umbiko Wokuhlolwa Kwebha Yensimbi Engagqwali

Kungani Usikhethe:

1. Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani inani elingenzeka.

2. Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokudiliva umnyango nomnyango. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

3. Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina.(Imibiko izovela ngokwemfuneko)

4. isiqinisekiso sokunikeza impendulo phakathi namahora angu-24(imvamisa ngehora elifanayo)

5. Nikeza umbiko we-SGS TUV.

6. Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

7.Nikeza isevisi eyodwa-stop.

Ukuqinisekisa Ikhwalithi yakwa-SAKY STEEL

1. Visual Dimension Test

2. Ukuhlolwa kwemishini njengokushuba, Ukwelula kanye nokunciphisa indawo.

3. Ukuhlaziywa komthelela

4. Ukuhlaziywa kokuhlolwa kwamakhemikhali

5. Ukuhlolwa kokuqina

6. Ukuhlolwa kokuvikela umgodi

7. Ukuhlolwa Okungenele

8. I-Intergranular Corrosion Testing

9. Ukuhlolwa Kokuqina

10. Ukuhlolwa Kokuhlola Kwe-Metallography

Iphakheji ye-SAKY STEEL'S:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,