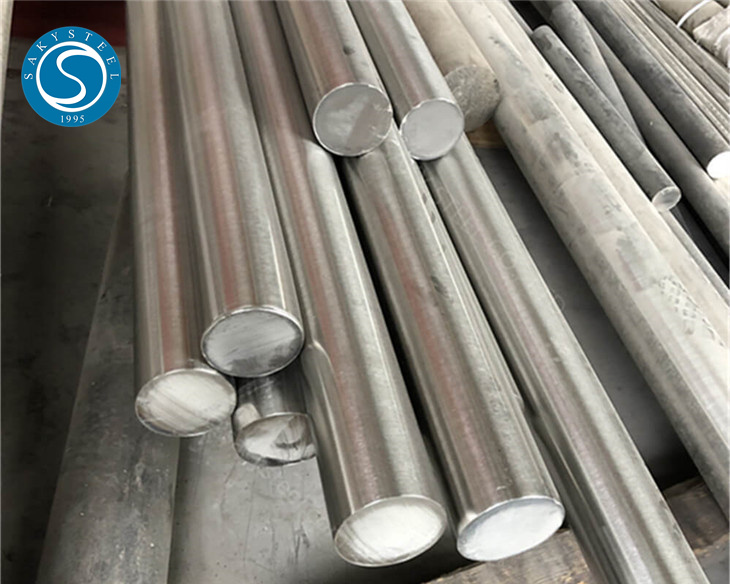

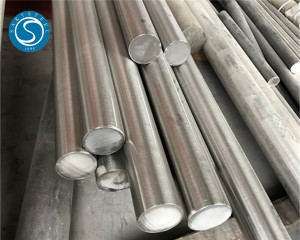

317/317L Ibha Yensimbi Engagqwali

Incazelo emfushane:

Ibha yensimbi engagqwali engu-317L, imelana nokugqwala futhi ifanele indawo enezinga lokushisa eliphezulu. Zitholele abahlinzeki bethu bebha yensimbi engenasici engu-317L nezintengo manje.

317 Amabha Ensimbi Engagqwali:

317 kanye nama-317L amabha ensimbi engagqwali angama-alloy high-alloy austenitic stainless steel anamazinga aphezulu e-chromium, nickel, ne-molybdenum uma kuqhathaniswa namamaki ajwayelekile afana no-304 no-316. Lezi zithuthukisi zinikeza ukumelana nokugqwala okuphakeme, ikakhulukazi ezindaweni ezine-asidi ezinensimbi engagqwali engu-317 kanye ne-317L yensimbi engenasici. amazinga aphezulu e-chromium, i-nickel, ne-molybdenum uma kuqhathaniswa namabanga ajwayelekile afana no-304 no-316. Lezi zithuthukisi zinikeza ukumelana nokugqwala okuphakeme, ikakhulukazi ezindaweni ezine-acidic. Amabha ensimbi engu-317 kanye no-317L ayizinto ze-premium ezilungele izinhlelo zokusebenza ezinzima ezidinga ukumelana nokugqwala okuphakeme, amandla, nokuqina.

Imininingwane Yebha Eyindilinga Yensimbi Engagqwali engu-317L:

| Ibanga | 317,317L. |

| Okujwayelekile | I-ASTM A276/A479 |

| Ubuso | hot rolled pickled , pholishiwe |

| Ubuchwepheshe | Kushiswe , Kwakhiwe, Kubanda phansi |

| Ubude | 1 kuya ku-12 Amamitha |

| Isitifiketi Sokuhlolwa Kwemishini | EN 10204 3.1 noma EN 10204 3.2 |

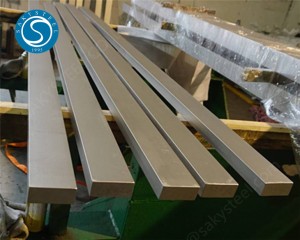

| Uhlobo | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging, njll. |

Ibha yensimbi engenasici ye-Chemical 317/317L:

| Ibanga | C | Mn | P | S | Si | Cr | Mo | Ni |

| 317 | 0.08 | 2.0 | 0.040 | 0.030 | 1.0 | 18.0-20.0 | 3.0-4.0 | 11.0-14.0 |

| 317L | 0.035 | 2.0 | 0.040 | 0.030 | 1.0 | 18.0-20.0 | 3.0-4.0 | 11.0-15.0 |

I-ASTM A276 317/317L Ibha Mechanical izakhiwo:

| Ukuminyana | I-Melting Point | I-Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 |

317/317L Izici Zebha Yensimbi Engagqwali

• Ukumelana Nokugqwala:Zombili izinsimbi ezingenasici ezingu-317 nezingu-317L zinikeza ukumelana okukhethekile emigodini, ukugqwala kwemifantu, kanye nokugqwala okuvamile ezindaweni ezinolaka, okufaka lezo eziqukethe i-sulfuric, i-acetic, i-formic, ne-citric acid.

• Amandla Aphezulu Nokuqina:Lawa ma-alloys agcina amandla awo kanye nokuqina kwawo ngisho nasezingeni eliphezulu lokushisa, okuwenza afanelekele ukusetshenziswa kwengcindezi ephezulu.

• Okuqukethwe Kwekhabhoni Ephansi ku-317L:I-"L" ku-317L imele okuqukethwe kwekhabhoni ephansi (isilinganiso esiphezulu esingu-0.03%), esiza ekwehliseni imvula ye-carbide ngesikhathi sokushisela, ngaleyo ndlela kugcinwe ukumelana nokugqwala kwe-alloy ezakhiweni ezishiselwe.

Kungani Khetha thina?

•Ungathola impahla ephelele ngokuvumelana nemfuneko yakho okungenani intengo engenzeka.

•Siphinde sinikeze ama-Reworks, i-FOB, i-CFR, i-CIF, nezintengo zokulethwa kwendlu ngendlu. Siphakamisa ukuthi wenze isivumelwano sokuthunyelwa okuzokonga kakhulu.

•Izinto esizihlinzekayo zingaqinisekiswa ngokuphelele, kusukela kusitifiketi sokuhlolwa kwempahla engavuthiwe kuya esitatimendeni sobukhulu bokugcina. (Imibiko izovela ngokwemfuneko)

•Siqinisekisa ukunikeza impendulo phakathi namahora angu-24 (imvamisa ngehora elifanayo)

•Nikeza umbiko we-SGS TUV.

•Sizinikele ngokugcwele kumakhasimende ethu. Uma kungeke kwenzeke ukuhlangabezana nezidingo zakho ngemva kokuhlola zonke izinketho, ngeke sikudukise ngokwenza izithembiso ezingamanga ezizodala ubudlelwano obuhle namakhasimende.

•Nikeza isevisi eyodwa-stop.Kusukela ekuthengeni impahla engavuthiwe kuya ekulethweni kokugcina, yonke le nqubo iyabonakala futhi iyalandeleka.

Ibha yensimbi engagqwali engu-317L engagqwali:

1. Ukupakisha kubaluleke kakhulu ikakhulukazi endabeni yokuthunyelwa kwamanye amazwe lapho impahla idlula eziteshini ezihlukahlukene ukuze ifike lapho kuyiwa khona, ngakho sibeka ukukhathazeka okukhethekile mayelana nokupakisha.

2. I-Saky Steel ipakisha izimpahla zethu ngezindlela eziningi ngokusekelwe emikhiqizweni. Sipakisha imikhiqizo yethu ngezindlela eziningi, njengokuthi,