Imijelo yentsimbi yeStainless H

Inkcazelo emfutshane:

“Imijelo ye-H” ibhekisa kumacandelo esakhiwo amile njengonobumba “H” asetyenziswa ngokuqhelekileyo kulwakhiwo kunye nezakhiwo ezahlukeneyo zokusebenza.

Imijelo yentsimbi yeStainless H:

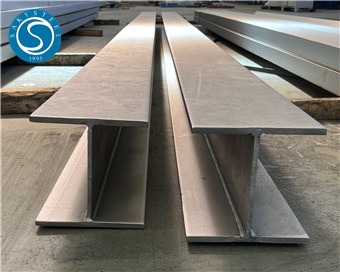

Imijelo yentsimbi ye-Stainless H zizinto zesakhiwo ezibonakaliswe yi-H-shaped cross-section.Ezi tshaneli zenziwe ngentsimbi engatyiwayo, ingxubevange enganyangekiyo ekwaziwa ngokuqina kwayo, ucoceko, kunye nesibheno sobuhle.Iziteshi zensimbi ezingenasici ze-H zifumana izicelo kumashishini ahlukeneyo, kubandakanywa ukwakhiwa, ukwakhiwa, kunye nokuvelisa, apho ukuxhathisa ukubola kunye namandla kubenza kube yinto ekhethiweyo yokuxhaswa kwesakhiwo kunye noyilo. izinto zesakhiwo apho zombini amandla kunye nenkangeleko egudisiweyo ibalulekile.

IiNkcazo zeMijelo ye-H:

| IBanga | 302,304,314,310,316,321 njl. |

| Umgangatho | ASTM A276, GB/T 11263-2010,ANSI/AISC N690-2010,EN 10056-1:2017 |

| Umphezulu | ishushu esongwayo ivundiwe, igudisiwe |

| Iteknoloji | I-Hot Rolled, i-Welded |

| Ubude | 1 ukuya kwi-6 yeemitha |

Iimpawu kunye neeNzuzo:

•I-"H" -i-design cross-shaped cross-section ye-I-beam yensimbi inikezela umthamo obalaseleyo wokuthwala imithwalo yomibini kunye nokuthe tye.

•Uyilo lwesakhiwo sensimbi ye-I-beam inika umgangatho ophezulu wokuzinza, ukuthintela ukuguqulwa okanye ukugoba phantsi koxinzelelo.

•Ngenxa yobume bayo obukhethekileyo, intsimbi ye-I-beam ingasetyenziswa ngokuguquguqukayo kwizakhiwo ezahlukahlukeneyo, kubandakanywa imiqadi, iikholomu, iibhuloho kunye nokunye.

•Intsimbi ye-I-beam yenza ngokugqwesileyo ngokugoba kunye nokunyanzeliswa, iqinisekisa ukuzinza phantsi kweemeko ezinzima zokulayisha.

•Ngoyilo olusebenzayo kunye namandla aphezulu, intsimbi ye-I-beam ihlala ibonelela ngeendleko ezifanelekileyo.

•Intsimbi ye-I-beam ifumana ukusetyenziswa ngokubanzi kulwakhiwo, iibhulorho, izixhobo zoshishino, kunye nezinye iinkalo ezahlukeneyo, ezibonisa ukuguquguquka kwayo kwiiprojekthi ezahlukeneyo zobunjineli kunye nezakhiwo.

•Uyilo lwentsimbi ye-I-beam luvumela ukuba lulungelelanise ngakumbi kwiimfuno zokwakhiwa okuzinzileyo kunye noyilo, ukubonelela ngesisombululo esisebenzayo sokwakhiwa kweendlela zokusingqongileyo kunye nezakhiwo eziluhlaza.

Imijelo yoBume beMichiza H:

| IBanga | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Iipropati zoomatshini kwi-H Channels:

| IBanga | Amandla okuqina ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Kutheni Khetha thina?

•Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

•Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhambisa umnyango ukuya emnyango.Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

•Iimathiriyeli esizibonelelayo ziqinisekiswa ngokupheleleyo, ukusuka kwisiqinisekiso sovavanyo lwemathiriyeli ekrwada ukuya kwingxelo yokugqibela yomlinganiselo.(Iingxelo ziya kubonisa ngokwemfuneko)

•Siqinisekisa ukunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

•Nika ingxelo ye-SGS TUV.

•Sizinikele ngokupheleleyo kubathengi bethu.Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

•Ukubonelela ngenkonzo yokumisa enye.

Ziziphi iindlela ze-welding?

Iindlela ze-welding ziquka i-arc welding, i-gas shielded welding (i-MIG / MAG i-welding), i-welding ye-laser, i-laser welding, i-plasma arc welding, i-friction stir welding, i-welding ye-pressure, i-electron beam welding, njl. Indlela nganye inezicelo ezizodwa kunye neempawu, ezifanelekileyo ezahlukeneyo iintlobo zezixhobo zokusebenza kunye neemfuno zokuvelisa.I-arc isetyenziselwa ukuvelisa ukushisa okuphezulu, ukunyibilikisa isinyithi phezu kwendawo yokusebenza ukwenza uxhumano.Iindlela eziqhelekileyo ze-arc welding ziquka i-arc welding manual, i-argon arc welding, i-arc welding ephantsi kwamanzi, njl njl. Ubushushu obuveliswa kukuchasana busetyenziselwa ukunyibilikisa isinyithi phezu kwendawo yokusebenza ukwenza uxhumano.I-Resistance welding ibandakanya i-spot welding, i-seam welding kunye ne-bolt welding.

Ziziphi izinto eziluncedo zokuwelda i-arc emanzini?

I-arc welding efakwe emanzini ifanelekile kwi-automation kunye neendawo eziphezulu zevolumu.Inokugqiba inani elikhulu lomsebenzi we-welding ngexesha elifutshane kunye nokuphucula ukusebenza kakuhle kwemveliso.I-arc welding efakwe emanzini ifanelekile kwi-automation kunye neendawo eziphezulu zevolumu.Inokugqiba inani elikhulu lomsebenzi we-welding ngexesha elifutshane kunye nokuphucula ukusebenza kakuhle kwemveliso.Ukuwelda kwe-arc emanzini ngokuqhelekileyo kusetyenziselwa ukuwelda amashiti esinyithi angqindilili ngenxa yokuba ukungena kwawo okuphezulu kwangoku kunye nokungena okuphezulu kuyenza isebenze ngakumbi kwezi zicelo.Ekubeni i-weld igutyungelwe yi-flux, i-oksijini inokuthintelwa ngokufanelekileyo ukuba ingene kwindawo ye-weld, ngaloo ndlela inciphisa amathuba okuba ne-oxidation kunye ne-spatter. izakhono zabasebenzi.Kwi-welding ye-arc ephantsi kwamanzi, iingcingo ezininzi ze-welding kunye nee-arcs zingasetyenziswa ngaxeshanye ukufezekisa i-multi-channel (multi-layer) welding kunye nokuphucula ukusebenza kakuhle.

Intshayelelo kwimilo ye-H beam?

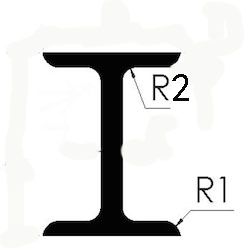

Imilo enqamlezayo yentsimbi ye-I-beam, eyaziwa ngokuba yi "工字钢" (gōngzìgāng) ngesiTshayina, ifana nonobumba "H" xa ivuliwe.Ngokukodwa, i-cross-section ibandakanya iibar ezimbini ezithe tye (iiflange) phezulu nasezantsi kunye nebar ephakathi ethe nkqo (iwebhu).Le milo "H" inika amandla aphezulu kunye nokuzinza kwintsimbi ye-I-beam, eyenza ibe yinto eqhelekileyo yesakhiwo ekwakhiweni kunye nobunjineli.Imilo eyilelwe i-I-beam yensimbi ivumela ukuba ifaneleke kwiinkqubo ezahlukeneyo zokuthwala kunye nenkxaso, ezifana njengemiqadi, iintsika, kunye nezakhiwo zebhulorho.Olu lungelelwaniso lwesakhiwo lwenza ukuba i-I-beam yentsimbi isasaze ngokufanelekileyo imithwalo xa iphantsi kwemikhosi, inikezela ngenkxaso enamandla.Ngenxa yobume obukhethekileyo kunye neempawu zesakhiwo, intsimbi ye-I-beam ifumana ukusetyenziswa ngokubanzi kwiindawo zokwakha kunye nobunjineli.

Indlela yokubonakalisa ubungakanani kunye nokubonakaliswa kwe-I-beam?

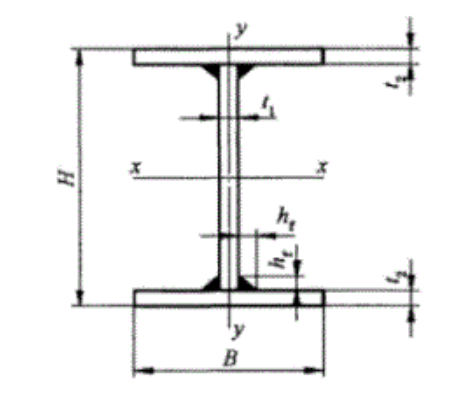

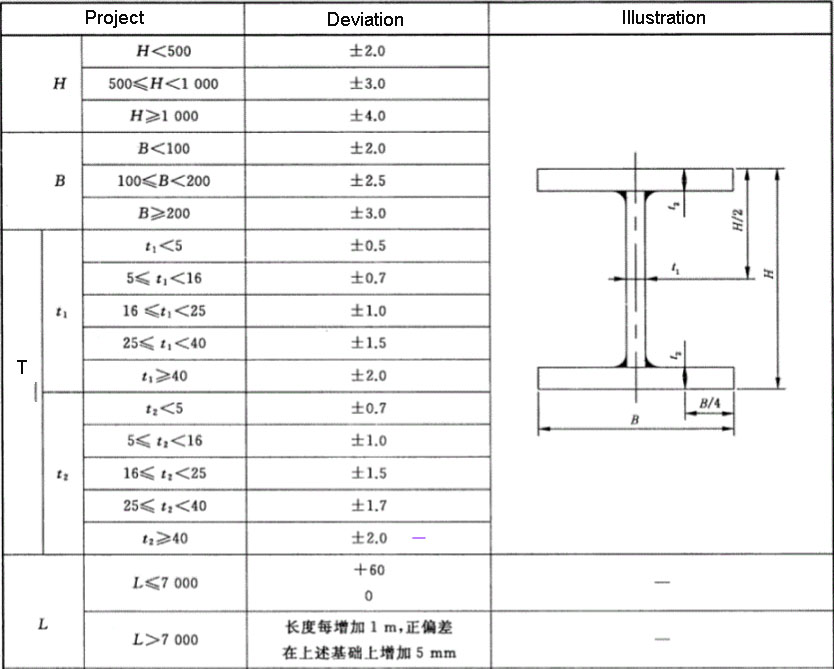

H——Phakamileyo

B——Ububanzi

t1——Ubukhulu bewebhu

t2——Ubukhulu bepleyiti yeFlange

h£——Ubungakanani bokuwelda (xa usebenzisa indibaniselwano ye-butt kunye ne-fillet welds, kufuneka ibe yisayizi ye-welding eqinisiweyo yomlenze we-hk)

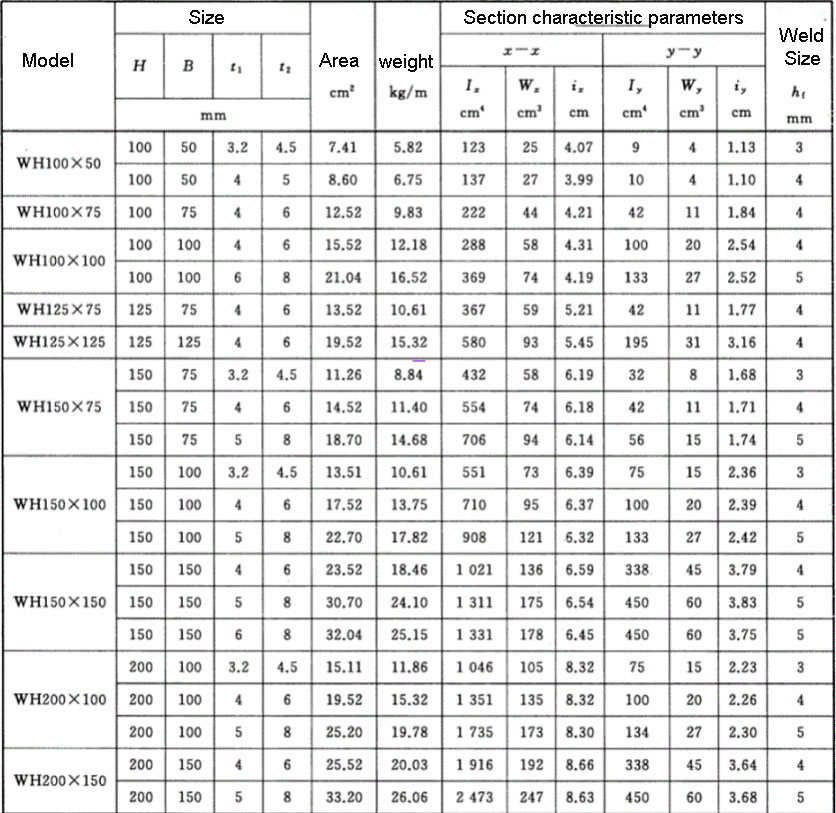

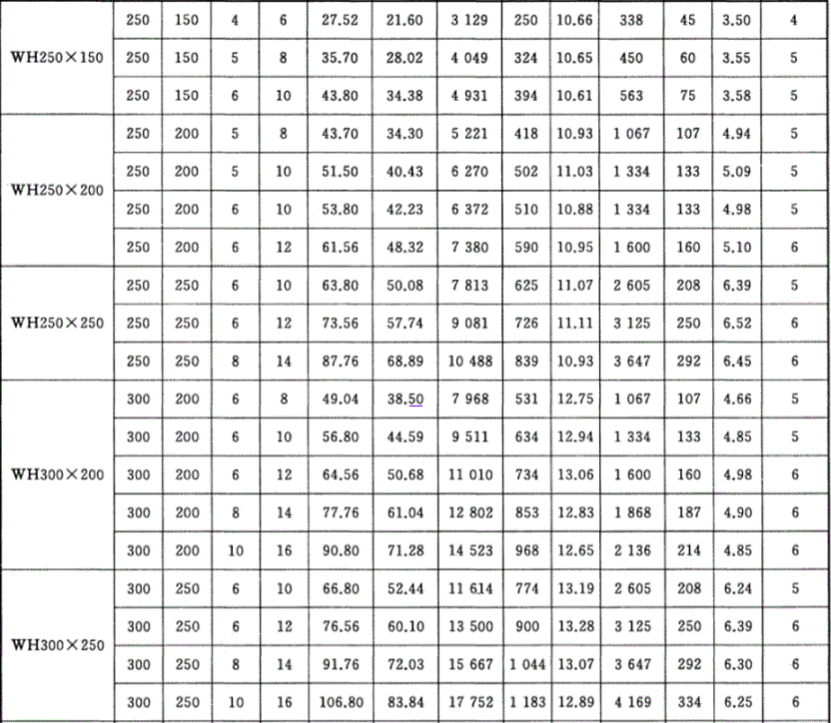

Imilinganiselo, iimilo kunye nokutenxa okuvumelekileyo kwentsimbi edityanisiweyo emile okwe-H

Imilinganiselo yamacandelo anqamlezileyo, indawo enqamlezileyo, ubunzima bethiyori kunye neempawu ezinqamlezileyo zeparamitha yentsimbi edityanisiweyo eyi-H.

Abathengi bethu

Iingxelo ezivela kubathengi bethu

Iziteshi ze-Stainless Steel H ziyinxalenye yezakhiwo eziguquguqukayo ezenziwe ngentsimbi ekumgangatho ophezulu.Ezi tshaneli zibonakalisa imo ehlukileyo "H", inika amandla aphuculweyo kunye nokuzinza kwizicelo ezahlukeneyo zokwakha kunye nezakhiwo.Ukugqiba okuthe tye kunye nokupholisiweyo kwensimbi engenasici yongeza umnxeba wobugcisa, okwenza ezi ziteshi ze-H zilungele zombini izinto ezisebenzayo nezibonakalayo zokuyila. Umzobo owenziwe ngu-H wandisa umthamo wokuthwala umthwalo, okwenza ezi ziteshi zilungele ukuxhasa imithwalo enzima ekwakhiweni nasekusetyenzweni kwezoshishino.Iziteshi ze-Stainless Steel H zifumana izicelo kumashishini ahlukeneyo, kubandakanywa ukwakhiwa, ukwakhiwa, kunye nokuvelisa, apho ukuxhaswa kwesakhiwo esomeleleyo kubalulekile.

Ukupakisha:

1. Ukupakishwa kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwempahla kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel's ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso.Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,