I-ER385 yentsimbi yokuwelda intsimbi

Inkcazelo emfutshane:

I-ER385 luhlobo lwetsimbi ye-welding filler, ngokukodwa i-electrode yensimbi engenasici. I-"ER" imele "i-Electrode okanye i-Rod," kwaye i-"385" ibonisa ukubunjwa kweekhemikhali kunye neempawu zetsimbi yokuzalisa. Kule meko, i-ER385 yenzelwe ukuwelda i-austenitic stainless steels.

I-ER385 intonga yokuwelda:

I-Austenitic stainless steels, ezifana ne-Type 904L, iqulethe amanqanaba aphezulu e-chromium, i-nickel, kunye ne-molybdenum, ezenza ukuba zikwazi ukumelana ne-corrosion kwaye zilungele ukusetyenziswa kwiindawo ezinzima. I-ER385 i-welding rods isetyenziswa ngokuqhelekileyo kwizicelo apho ukuxhatshazwa kwe-corrosion kuyinto ebalulekileyo, njengakwimichiza, i-petrochemical, kunye namashishini aselwandle.

Iinkcukacha zocingo lwe-ER385 wokuWelding:

| IBanga | ER304 ER308L ER309L,ER385 njl. |

| Umgangatho | AWS A5.9 |

| Umphezulu | Kuqaqambile, Kunamafu, Kuthafeni, Kumnyama |

| Ububanzi | MIG – 0.8 ukuya 1.6 mm,TIG – 1 ukuya 5.5 mm,Core ucingo – 1.6 ukuya 6.0 |

| Isicelo | Ngokuqhelekileyo isetyenziselwa ukuveliswa kunye nokulungiswa kweenqaba, iitanki, imibhobho kunye nokugcinwa kunye nezikhongozeli zokuthutha kwii-asidi ezomeleleyo ezahlukeneyo. |

Ukulingana nocingo lwe-Stainless Steel ER385:

| UMGANGATHO | WERKSTOFF NR. | UNS | I-JIS | BS | KS | I-FNOR | EN |

| ER-385 | 1.4539 | N08904 | SUS 904L | 904S13 | I-STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Ubume beMichiza ye-SUS 904L yocingo lwe-Welding:

Ngokomgangatho we-AWS A5.9

| IBanga | C | Mn | P | S | Si | Cr | Ni | Mo | Cu |

| ER385(904L) | 0.025 | 1.0-2.5 | 0.02 | 0.03 | 0.5 | 19.5-21.5 | 24.0-36.0 | 4.2-5.2 | 1.2-2.0 |

1.4539 Iipropati ze-Welding Rod Mechanical:

| IBanga | Amandla okuqina ksi[MPa] | Elongation % |

| I-ER385 | 75[520] | 30 |

Kutheni Khetha thina?

•Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

•Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhambisa umnyango ukuya emnyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

•Iimathiriyeli esizibonelelayo ziqinisekiswa ngokupheleleyo, ukusuka kwisiqinisekiso sovavanyo lwemathiriyeli ekrwada ukuya kwingxelo yokugqibela yomlinganiselo.(Iingxelo ziya kubonisa ngokwemfuneko)

•Siqinisekisa ukunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

•Nika ingxelo ye-SGS TUV.

•Sizinikele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

•Ukubonelela ngenkonzo yokumisa enye.

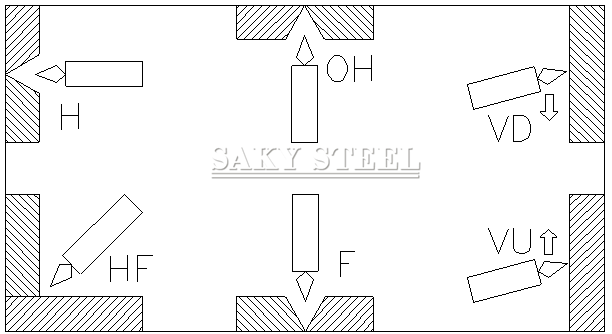

Iiparamitha zeWelding yangoku: DCEP (DC+)

| Ubume bedayamitha yocingo (mm) | 1.2 | 1.6 |

| Umbane (V) | 22-34 | 25-38 |

| Okwangoku (A) | 120-260 | 200-300 |

| Ubude owomileyo (mm) | 15-20 | 18-25 |

| Ukuhamba kwerhasi | 20-25 | 20-25 |

Ziziphi iimpawu ze-ER385 Welding Wire?

1. Ukumelana nokugqwesa okugqwesileyo, kunokumelana ne-corrosion efanayo ye-sulfuric acid kunye ne-phosphoric acid, ukuxhathisa ukubola kwe-acetic acid nakweyiphi na iqondo lokushisa kunye nokugxininiswa phantsi koxinzelelo oluqhelekileyo, kwaye inokusombulula ngokufanelekileyo i-pitting corrosion, i-pitting corrosion, i-crevice corrosion, i-corrosion yoxinzelelo kunye nezinye iingxaki ze-halides.

2. I-arc ithambile kwaye izinzile, kunye ne-spatter encinci, i-shape enhle, ukususwa kwe-slag efanelekileyo, ukondla ucingo oluzinzileyo, kunye nokusebenza kakuhle kwenkqubo ye-welding.

Izikhundla ze-welding kunye nezinto ezibalulekileyo:

1. Sebenzisa imiqobo yokumelana nomoya xa uwelda kwiindawo ezinomoya ukuthintela imingxunya ebangelwa ngumoya onamandla.

2. Ubushushu phakathi kokudlula bulawulwa kwi-16-100℃.

3. Ukufuma, ama-rust stains kunye ne-oil stains phezu kwesiseko sesinyithi kufuneka sisuswe ngokupheleleyo phambi kwe-welding.

4. Sebenzisa igesi ye-CO2 ye-welding, ubunyulu kufuneka bube ngaphezu kwe-99.8%, kwaye ukuhamba kwegesi kufuneka kulawulwe kwi-20-25L / min.

5. Ubude obomileyo bokwandiswa kocingo lwe-welding kufuneka balawulwe ngaphakathi koluhlu lwe-15-25mm.

6. Emva kokukhupha ucingo lwe-welding, nceda uqaphele: thatha amanyathelo obungqina bomswakama, uyisebenzise ngokukhawuleza, kwaye ungashiyi ucingo lwe-welding olungasetyenziswanga luvezwe emoyeni ixesha elide.

Abathengi bethu

I-Stainless Steel I Beams Packing:

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,