347 uMbhobho weNtsimbi engenaMthungo

Inkcazelo emfutshane:

I-347 yentsimbi engenamthungo uMbhobho: Ukuxhathisa koBubushushu obuphezulu kunye nokuKhuselwa kokuMhlwa.

UVavanyo lokuRhwaba kombhobho wentsimbi:

I-347 ye-Stainless Steel Seamless Pipes yenziwe kwibakala elizinzileyo lensimbi engenasici, eyenzelwe ukunika ukuxhathisa okugqwesileyo kwi-intergranular corrosion, ngakumbi kwiindawo ezinobushushu obuphezulu. Le mibhobho ifanelekile kwizicelo ezifuna amandla aphezulu okurhubuluza kunye nokumelana ne-oxidation, njengokusetyenzwa kweekhemikhali, ukuveliswa kwamandla, kunye neenkqubo zokukhupha ukushisa okuphezulu. Nge-niobium eyongeziweyo, i-347 insimbi engenasici inikezela ukuzinza okuphuculweyo, ukuthintela imvula ye-carbide kunye nokugcina amandla ayo kumaqondo okushisa ukuya kwi-1500 ° F (816 ° C). Oku kwenza imibhobho engama-347 yentsimbi engenamthungo igqibelele ukulungiselela iimeko ezifuna ukuqina kunye nokuthembeka kwexesha elide.

Iinkcukacha zoMbhobho weStainless Steel 347 ongenamthungo:

| Iinkcukacha | ASTM A/ASME SA213, A249, A269, A312, A358, A790 |

| IBanga | 304, 316, 321, 321Ti, 347, 347H, 904L, 2205, 2507 |

| Ubuchule | Ishushu, itsalwa ngokubanda |

| Ubungakanani | 1 / 8" QAPHELA - 12" QAPHELA |

| Ukutyeba | 0.6 mm ukuya kwi-12.7 mm |

| Ishedyuli | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Uhlobo | Ayinamthungo |

| Ifom | Uxande, Round, Square, Hydraulic Etc |

| Ubude | 5.8M, 6M kunye noBubude obufunekayo |

| Isiphelo | Isiphelo esiBeveled, isiphelo esicacileyo, sinyathelwe |

| Mill Test Certificate | EN 10204 3.1 okanye EN 10204 3.2 |

I-Stainless Steel 347/347H Imibhobho eLinganayo:

| UMGANGATHO | WERKSTOFF NR. | UNS | I-JIS | IGOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| I-SS 347H | 1.4961 | S34709 | I-SUS 347H | - | X6CrNiNb18-12 |

I-347 iityhubhu yentsimbi engenasici Ukubunjwa kwemichiza:

| IBanga | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 ubuninzi | 2.0 ubuninzi | 1.0 ubuninzi | 0.045 ubuninzi | 0.030 ubuninzi | 17.00 - 20.00 | 10xC - 1.10 | 9.00 - 13.00 | 62.74 min |

| I-SS 347H | 0.04 - 0.10 | 2.0 ubuninzi | 1.0 ubuninzi | 0.045 ubuninzi | 0.030 ubuninzi | 17.00 - 19.00 | 8xC - 1.10 | 9.0 -13.0 | 63.72 min |

347 iinkcazelo ngeempawu zombhobho wentsimbi engatyiwayo:

| Ukuxinana | Indawo yokunyibilika | Tensile strength | Ukomelela kweSivuno (0.2% i-offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

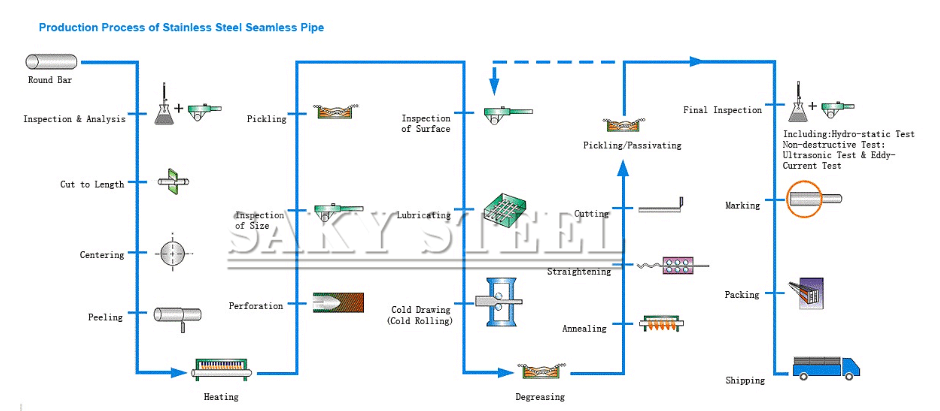

Iinkqubo zeMibhobho yeStainless Steel engenamthungo:

347 iStainless Steel engenaMthungo yosetyenziso lwemibhobho:

I-1.Izixhobo zokuLungisa iChemical - Efanelekileyo kutshintshiselwano lokushisa, ii-reactors, kunye neenkqubo zemibhobho ezibamba iikhemikhali ezinobungozi kumaqondo aphezulu.

I-2.I-Petrochemical Industry - Isetyenziswe kwimisebenzi yokucoca yokuphatha ulwelo kunye neegesi kumaqondo okushisa aphezulu.

I-3.Izixhobo ze-Aerospace - Isetyenziswe kwiindawo ze-injini kunye neenkqubo zokukhupha ezifuna ukushisa kunye nokumelana ne-oxidation.

I-4.I-Power Generation - Isetyenziswe kwiibhoilers, ii-superheaters, kunye nezinye iinkqubo zokushisa okuphezulu ukuze zikwazi ukumelana nokuhamba ngebhayisikili ye-thermal.

I-5.Ukutya kokutya - Kuqeshwe kwiinkqubo apho i-steam ephezulu yokushisa isetyenziswe, kwaye ukuchasana ne-oxidation kunye ne-corrosion kuyimfuneko.

I-6.Izixhobo ze-Pharmaceutical - Ifanelekile kwimibhobho kunye namatanki abonakaliswe kwiikhemikhali kwiindawo ezingenanto.

Kutheni Khetha Thina?

1.Ngeminyaka engama-20 yamava, iqela lethu liqinisekisa umgangatho kuyo yonke iprojekthi.

2.Sinamathela kwiinkqubo ezingqongqo zokulawula umgangatho ukuqinisekisa ukuba yonke imveliso ihlangabezana nemigangatho.

3.Sisebenzisa itekhnoloji yamva nje kunye nezisombululo ezintsha zokuhambisa iimveliso eziphezulu.

4.Sinikezela ngamaxabiso akhuphisanayo ngaphandle kokuthomalalisa umgangatho, ukuqinisekisa ukuba ufumana elona xabiso lilungileyo kutyalo-mali lwakho.

5.Sinikezela ngoluhlu olubanzi lweenkonzo ukuhlangabezana nazo zonke iimfuno zakho, ukusuka ekudibaneni kokuqala ukuya kunikezelo lokugqibela.

6.Ukuzinikela kwethu ekuzinzeni nasekuziphatheni okusesikweni kuqinisekisa ukuba iinkqubo zethu zihambelana nokusingqongileyo.

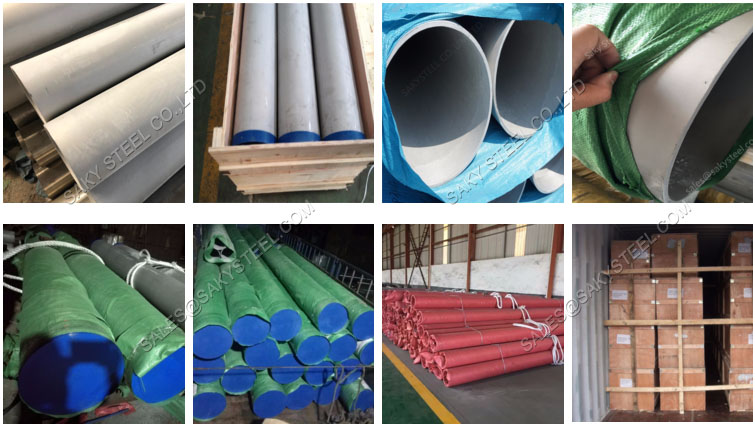

ukuPakisha uMbhobho weNtsimbi onganyangekiyo:

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,