317 umbhobho wentsimbi engenamthungo

Inkcazelo emfutshane:

| Iinkcukacha zeumbhobho wentsimbi engenamthungo: |

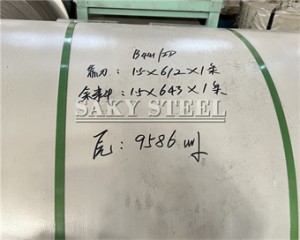

Imibhobho engenamthungo kunye nobungakanani beMibhobho :1/8″ QAPHELA – 24″ QAPHELA

Iinkcukacha :ASTM A/ASME SA213, A249, A269, A312, A358, A790

Umgangatho :ASTM, ASME

Ibakala:304, 316,317,317L, 321, 321Ti, 420, 430, 446, 904L, 2205, 2507

Ubuchwephesha:Ishushu, itsalwa ngokubanda

Ubude :5.8M, 6M kunye noBubude obufunekayo

Ububanzi bangaphandle :6.00 mm OD ukuya kuthi ga kwi-914.4 mm OD, Ubukhulu ukuya kuma-24” NB

Ukutyeba :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Ishedyuli :SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Iintlobo :Imibhobho engenamthungo

Ifom :Round, Square, Rectangle, Hydraulic, Honed Tubes

Isiphelo :Isiphelo esicacileyo, isiphelo esiBeveled, sinyathelwe

| Intsimbi engatyiwa 317/317L Imibhobho engenamthungo kumaBanga aLingeneyo: |

| UMGANGATHO | WERKSTOFF NR. | UNS | I-JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

| I-SS 321 / 321H iMibhobho engenamthungo Ukubunjwa kweMichiza kunye neempawu zoomatshini: |

| Amabanga | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 ubuninzi | 2.0 ubuninzi | 1.0 ubuninzi | 0.045 ubuninzi | 0.030 ubuninzi | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 ubuninzi | 2.0 ubuninzi | 1.0 ubuninzi | 0.045 ubuninzi | 0.030 ubuninzi | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

| Ukuxinana | Indawo yokunyibilika | Tensile strength | Ukomelela kweSivuno (0.2% i-offset) | Ukwandisa |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| Kutheni Ukhetha Thina : |

1. Unokufumana izinto ezigqibeleleyo ngokwemfuno yakho ngexabiso elincinci elinokwenzeka.

2. Sikwabonelela ngeeReworks, FOB, CFR, CIF, kunye namaxabiso okuhanjiswa kweminyango. Sicebisa ukuba wenze isivumelwano sokuthumela ngenqanawe okuya kuba nokonga kakhulu.

3. Izinto esizibonelelayo zingqinisiseka ngokupheleleyo, ukusuka kwisatifikethi sovavanyo lwemathiriyeli ekrwada ukuya kwisiteyitimenti somgangatho wokugqibela.(Iingxelo ziya kubonisa ngokwemfuneko)

4. isiqinisekiso sokunika impendulo kwiiyure ezingama-24(ngokuqhelekileyo ngeyure enye)

5. Unokufumana ezinye iindlela zesitokhwe, ukuhanjiswa kwelitye kunye nokunciphisa ixesha lokuvelisa.

6. Sizinikezele ngokupheleleyo kubathengi bethu. Ukuba akunakwenzeka ukuhlangabezana neemfuno zakho emva kokuvavanya zonke iinketho, asiyi kukukhohlisa ngokwenza izithembiso zobuxoki eziza kudala ubudlelwane obuhle kubathengi.

| UQinisekiso loMgangatho we-SAKY STEEL (kubandakanywa zombini ezonakalisi nezingonakalisiyo) : |

1. Uvavanyo lweDimension Visual

2. Uvavanyo lobuchwephesha olufana ne-tensile, Ukwandiswa kunye nokunciphisa indawo.

3. Uvavanyo olukhulu

4. Uhlalutyo loviwo lwekhemikhali

5. Uvavanyo lokuqina

6. Uvavanyo lokukhuselwa komngxuma

7. Uvavanyo lwe-Flaring

8. Uvavanyo lweJethi yamanzi

9. Uvavanyo olungeneyo

10. Uvavanyo lweX-ray

11. Uvavanyo lwe-Intergranular Corrosion

12. Uhlalutyo lwempembelelo

13. Eddy uviwo lwangoku

14. Uhlalutyo lwe-Hydrostatic

15. Uvavanyo loVavanyo lweMetallography

| Iinkcukacha zocingo lwe-Incoloy A286: |

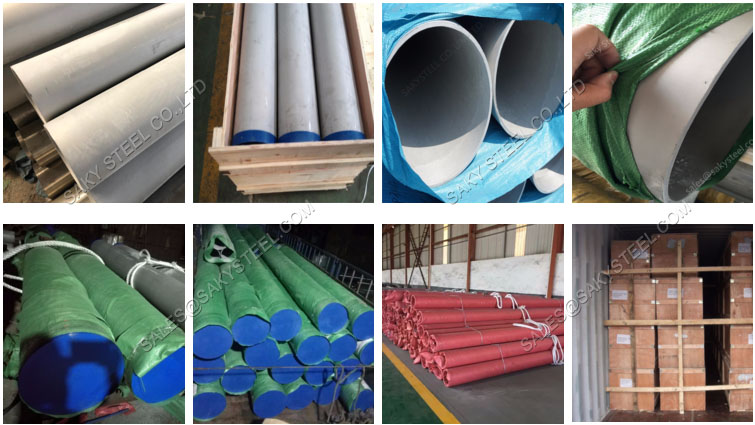

1. Ukupakisha kubaluleke kakhulu ngokukodwa kwimeko yokuthunyelwa kwamanye amazwe apho umthwalo udlula kwiitshaneli ezahlukeneyo ukuya kufika kwindawo yokugqibela, ngoko ke sibeka inkxalabo ekhethekileyo malunga nokupakishwa.

2. I-Saky Steel ipakisha iimpahla zethu ngeendlela ezininzi ezisekelwe kwiimveliso. Sipakisha iimveliso zethu ngeendlela ezininzi, ezinje,

Usetyenziso:

1. Iinkampani zePhepha kunye nePulp

2. Izicelo zoxinzelelo oluphezulu

3. Ishishini leoli negesi

4. Ukucoca imichiza

5. Umbhobho

6. Ukusetyenziswa kobushushu obuphezulu

7. ILin yePipe yamanzi

8. Amaziko oMbane weNyukliya

9. Ukwenziwa kokutya kunye namashishini obisi

10. I-Boiler kunye ne-Heat Exchangers