diaméterna badag pipah Seamless Stainless Steel

Katerangan pondok:

| Spésifikasi pipa stainless steel Seamless: |

| 1. Standar: | ASTM A312 A213 A269 A511 A789 A790, JIS3463, JIS3459, DIN2462, DIN17456 |

| 2. Kelas: | 304,310S,316,316L,321,321H,317L,904L,2205, jsb |

| 3. Rentang OD: | 200-800mm |

| 4. Tembok Ketebalan Range: | SCH-5S, SCH-10S, SCH-20S, SCH-40 |

| 5. Surface finish: | Pickled, Caang, Sandblast, Polishing, jsb |

| 6. Téhnik: | Hot-digulung, tiis-ditarik |

| 7. Tes: | Analisis Kimia, Hidrostatik atanapi Nondestructive Electric Test, Intergranular Corrosion Test, Flaring Test,Tes Ngampar,Uji Flange, Uji Ukuran Grain, Uji Udara Dina Cai, Uji Ultrasonik, Uji Arus Eddy |

| 8. bungkusan: | kebat. Kasus lapis. Tungtung Caps on duanana tungtung |

| Komposisi kimiawi: |

| Kelas | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 201 | .15 Maks | 5.5 - 7.5 | 1.00 Max | .060 Max | .030 Max | 16 - 18 | 3.5-5.5 | .25 Maks | |

| 202 | .15 Maks | 5.5 - 7.5 | 1.00 Max | .060 Max | .030 Max | 16 - 18 | 3.5-5.5 | .25 Maks | |

| 301 | 0,15 max | 2.00 max | 1,00 max | 0,045 max | 0,030 max | 16-18 | 6–8 | 0.10 | |

| 302 | 0.15 | 2.00 max | 0.75 | 0.05 | 0.03 | 17–19 | - | 8–10 | 0.10 |

| 302B | 0.15 | 2.00 max | 2.0–3.0 | 0.05 | 0.03 | 17–19 | - | 8–10 | - |

| 304 | 0.08 | 2.00 max | 0.75 | 0.05 | 0.03 | 18-20 | - | 8-10.5 | 0.10 |

| 304L | 0.03 | 2.00 max | 0.75 | 0.05 | 0.03 | 18-20 | 6–12 | 0.10 | |

| 304H | 0.04-0.01 | 2.00 max | 0.75 | 0.05 | 0.03 | 18-20 | 8-10.5 | - | |

| 310 | 0.25 | 2.00 max | 1.50 | 0.05 | 0.03 | 24-26 | - | 19-22 | - |

| 310S | 0.08 | 2.00 max | 1.50 | 0.05 | 0.03 | 24-26 | - | 19-22 | - |

| 316 | 0.08 | 2.00 max | 0.75 | 0.05 | 0.03 | 16-15 | 2–3 | 10–14 | 0.10 |

| 316L | 0.03 | 2.00 max | 0.75 | 0.05 | 0.03 | 16-18 | 2–3 | 10–14 | 0.10 |

| 321 | 0.08 | 2.00 max | 0.75 | 0.05 | 0.03 | 17–19 | 9–12 | 0.10 | |

| 410 | .080-.150 | 1,00 max | 1.00 Max | 0.04 | 0,030 max | 11.5-13.5 | 0,75 max |

| Pipa Stainless Steel Diaméterna ageung JIS G3468, SSP 13517 Spésifikasi: |

| Nominal | Nominal | Di luar | SCH-5S | SCH-10S | SCH-20S | SCH-40 |

| diaméterna | diaméterna | Diaméterna (mm) | Ketebalan Tembok Nominal (mm) | Ketebalan Tembok Nominal (mm) | Ketebalan Tembok Nominal (mm) | Ketebalan Tembok Nominal (mm) |

| A | B | |||||

| 150 | 6 | 165.2 | 2.8 | 3.4 | 5 | 7.1 |

| 200 | 8 | 216.3 | 2.8 | 4 | 6.5 | 8.2 |

| 250 | 10 | 267.4 | 3.4 | 4 | 6.5 | 9.3 |

| 300 | 12 | 318.5 | 4 | 4.5 | 6.5 | 10.3 |

| 350 | 14 | 355.6 | 4 | 5 | 8 | 11.1 |

| 400 | 16 | 406.4 | 4.5 | 5 | 8 | 12.7 |

| 450 | 18 | 457.2 | 4.5 | 5 | 8 | 14.3 |

| 500 | 20 | 508 | 5 | 5.5 | 9.5 | 15.1 |

| 550 | 22 | 558.8 | 5 | 5.5 | 9.5 | 15.9 |

| 600 | 24 | 609.6 | 5.5 | 6.5 | 9.5 | 17.5 |

| 650 | 26 | 660.4 | 5.5 | 8 | 12.7 | - |

| 700 | 28 | 711.2 | 5.5 | 8 | 12.7 | - |

| 750 | 30 | 762 | 6.5 | 8 | 12.7 | - |

| 800 | 32 | 812.8 | - | 8 | 12.7 | - |

| 850 | 34 | 863.6 | - | 8 | 12.7 | - |

| 900 | 36 | 914.4 | - | 8 | 12.7 | - |

| 1000 | 40 | 1016 | - | 9.5 | 14.3 | - |

| 1050 | 42 | 1066.8 | Nalika diménsi salian ti anu dipasihkeun dina tabel anu disebatkeun di luhur diperyogikeun, ukuran cangkang ditangtukeun sakumaha anu disatujuan antara anu mésér sareng produsén (sakysteel) | |||

| | | | | | | ||||

| 1650 | 66 | 1676.4 | ||||

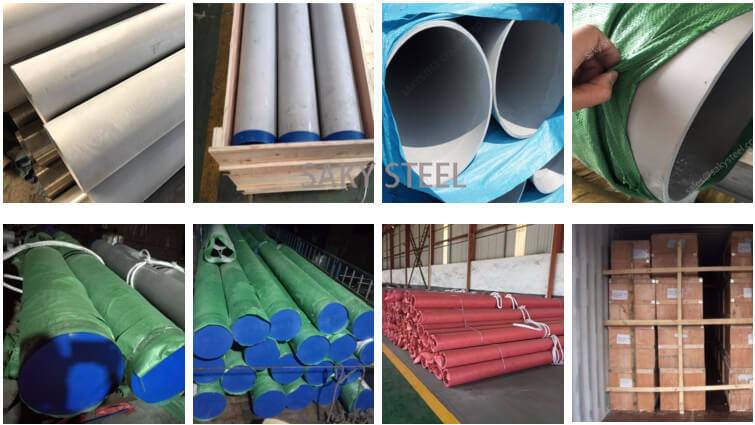

| Bungkusan & Pangiriman: |

Émbaran bungkusan tina stainless steel pipa seamless:

PVC packing, karton packing, atawa sakumaha pamundut customer kasus kai.

Inner packing: 1 kantong plastik (polythene) / sapotong, sarta 500kgs dipak dina hiji kebat.

packing luar: kertas Kraft, kasus kai atawa nurutkeun requests konsumén '.

Pipa Stainless Steel Diaméterna ageung kedah sumping kalayan aman, gancang sareng tanpa karusakan di tujuanana di mana waé di dunya.

Bungkusan ogé bagian penting tina jaminan kualitas.

Aplikasi:

Sakysteel utamana dipaké salaku pipe pangeboran pikeun géologi minyak bumi, cracking pipe pikeun industri pétrokimia, pipe alat keur ngagolakkeun, bearing pipe na-precision tinggi pipe struktural pikeun mobil, traktor jeung aviation.