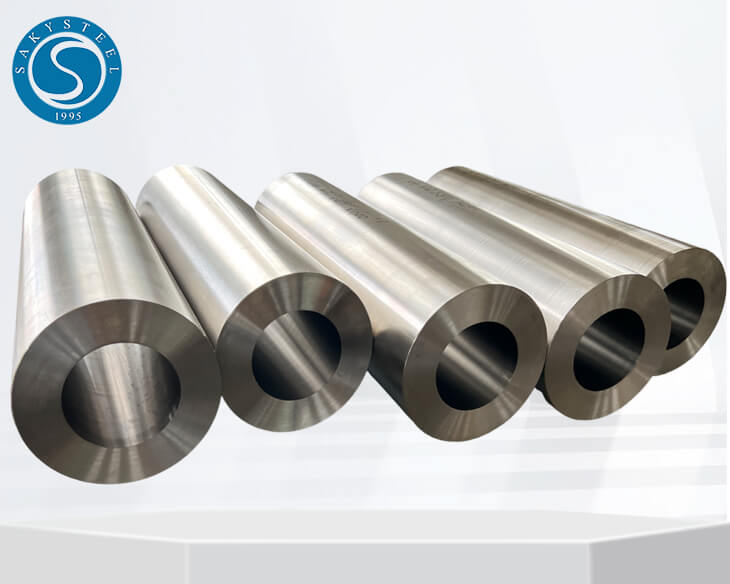

Stainless Steel Hollow Bar

Short Description:

Looking for Stainless Steel Hollow Bars? We supply seamless and welded stainless steel hollow bars in 304, 316, and other grades.

Stainless Steel Hollow Bar:

A hollow bar is a metal bar featuring a central bore that extends through its entire length. Manufactured similarly to seamless tubes, it is extruded from a forged bar and then precision-cut to the desired shape. This production method enhances mechanical properties, often resulting in greater consistency and improved impact toughness compared to rolled or forged components. Additionally, hollow bars offer excellent dimensional accuracy and uniformity, making them a reliable choice for applications requiring high performance and precision.

Specifications Of Stainless Steel Hollow Bar

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

| Surface | Bright,Polishing,Pickled,Peeled,Black,Grinding,Mill,Mirror,Hairline etc |

| Technology | Cold Drawn,Hot Rolled,Forged |

| Specifications | as required |

| Tolerance | H9, H11, H13, K9, K11, K13 or as required |

More details of Stainless steel hollow bar

| SIZE(mm) | MOQ(kgs) | SIZE(mm) | MOQ(kgs) | SIZE(mm) | MOQ(kgs) |

| 32 x 16 32 x 20 32 x 25 36 x 16 36 x 20 36 x 25 40 x 20 40 x 25 40 x 28 45 x 20 45 x 28 45 x 32 50 x 25 50 x 32 50 x 36 56 x 28 56 x 36 56 x 40 63 x 32 63 x 40 63 x 50 71 x 36 71 x 45 71 x 56 75 x 40 75 x 50 75 x 60 80 x 40 80 x 50 |

200kgs | 80 x 63 85 x 45 85 x 55 85 x 67 90 x 50 90 x 56 90 x 63 90 x 71 95 x 50 100 x 56 100 x 71 100 x 80 106 x 56 106 x 71 106 x 80 112 x 63 112 x 71 112 x 80 112 x 90 118 x 63 118 x 80 118 x 90 125 x 71 125 x 80 125 x 90 125 x 100 132 x 71 132 x 90 132 x 106 |

200kgs | 140 x 80 140 x 100 140 x 112 150 x 80 150 x 106 150 x 125 160x 90 160 x 112 160 x 132 170 x 118 170 x 140 180 x 125 180 x 150 190 x 132 190 x 160 200 x 160 200 x 140 212 x 150 212 x 170 224 x 160 224 x 180 236 x 170 236 x 190 250 x 180 250 X 200 305 X 200 305 X 250 355 X 255 355 X 300 |

350kgs |

| Remarks: O.D x I.D (mm) | |||||

| Size | Chucked true to OD | Chucked true to ID | |||

| OD, | ID, | Max.OD, | Max.ID, | Min.OD, | Min.ID, |

| mm | mm | mm | mm | mm | mm |

| 32 | 20 | 31 | 21.9 | 30 | 21 |

| 32 | 16 | 31 | 18 | 30 | 17 |

| 36 | 25 | 35 | 26.9 | 34.1 | 26 |

| 36 | 20 | 35 | 22 | 34 | 21 |

| 36 | 16 | 35 | 18.1 | 33.9 | 17 |

| 40 | 28 | 39 | 29.9 | 38.1 | 29 |

| 40 | 25 | 39 | 27 | 38 | 26 |

| 40 | 20 | 39 | 22.1 | 37.9 | 21 |

| 45 | 32 | 44 | 33.9 | 43.1 | 33 |

| 45 | 28 | 44 | 30 | 43 | 29 |

| 45 | 20 | 44 | 22.2 | 42.8 | 21 |

| 50 | 36 | 49 | 38 | 48 | 37 |

| 50 | 32 | 49 | 34.1 | 47.9 | 33 |

| 50 | 25 | 49 | 27.2 | 47.8 | 26 |

| 56 | 40 | 55 | 42 | 54 | 41 |

| 56 | 36 | 55 | 38.1 | 53.9 | 37 |

| 56 | 28 | 55 | 30.3 | 53.7 | 29 |

Applications of Stainless Steel Hollow Bar

1.Oil & Gas Industry: Used in drilling tools, wellhead equipment, and offshore structures due to their durability and resistance to harsh environments.

2.Automotive & Aerospace: Ideal for lightweight structural components, shafts, and hydraulic cylinders that require high strength and impact resistance.

3.Construction & Infrastructure: Applied in architectural frameworks, bridges, and support structures where corrosion resistance and strength are essential.

4.Machinery & Equipment: Used in precision-engineered parts such as hydraulic and pneumatic cylinders, drive shafts, and bearings.

5.Food & Pharmaceutical Processing: Preferred for hygienic applications such as conveyor systems, processing equipment, and storage tanks due to their non-reactive surface.

6.Marine Industry: Utilized in shipbuilding and offshore platforms, offering excellent resistance to saltwater corrosion.

Unique Features of Stainless Steel Hollow Bar

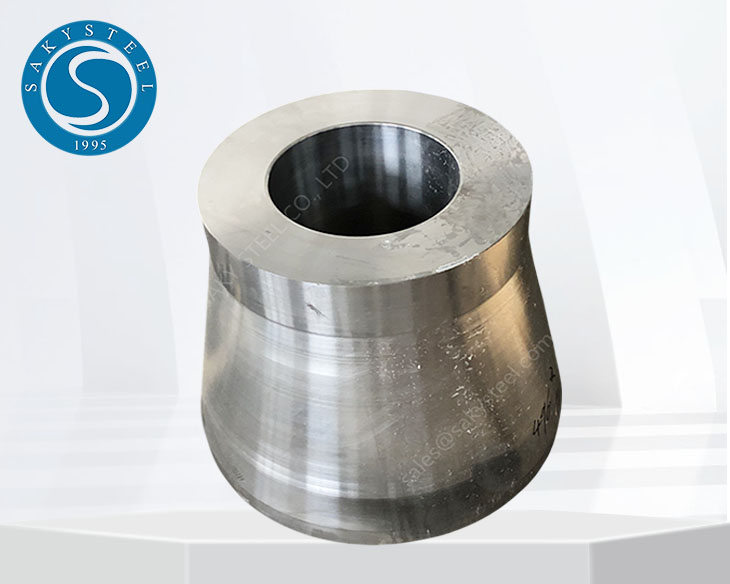

The primary distinction between a stainless steel hollow bar and a seamless tube lies in wall thickness. While tubes are specifically designed for fluid transport and typically only require machining at the ends for fittings or connectors, hollow bars have significantly thicker walls to accommodate further machining into finished components.

Opting for hollow bars instead of solid bars offers clear advantages, including material and tooling cost savings, reduced machining time, and improved productivity. Since hollow bars are closer to the final shape, less material is wasted as scrap, and tooling wear is minimized. This translates to immediate cost reductions and more efficient resource utilization.

More importantly, minimizing or eliminating machining steps significantly enhances manufacturing efficiency. This can lead to lower machining costs per part or increased production capacity when machines are operating at full capacity. Additionally, using stainless steel hollow bars eliminates the need for trepanning when producing components with a central bore—an operation that not only hardens the material but also complicates subsequent machining processes.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,