Stainless steel centerless grinding bar

Short Description:

Saky Steel is a leading manufacturer of Stainless steel centerless grinding bar. Our stainless centerless grinding bar has manufactured as per international standard for any machining and industrial applications. Our centerless grinding bar are one of the most appreciable products for various applications like machining tools, fasteners, automotive applications, pump shafts, motor shafts, valve and many more.

Our stainless steel centerless grinding bar is one of the most extensive range of bars for various components manufacturing in the market. It has strong corrosion resistance ability and low maintenance characteristics which make it an absolute product for a wide range of applications.

Our stainless steel bright round bars have various grades and different size. We also provide manufacturing service as per client requirements.

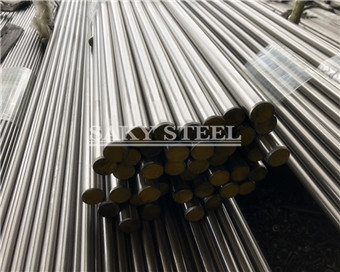

| Stainless Steel Round Bar Bright Products Show: |

| Stainless Steel centerless grinding bar Grades: |

| Specification: | ISO 286-2 |

| Stainless Steel Round Bars: | Outside Diameter in the range of 4mm to 50mm |

| Austenitic Grade(300series) | 303, 303Cu, 303F, 304,304L,304F, SUS316,316L,316L,316LF,316LS, |

| Ferritic Grade(400series) | 416, 416F,420,420F,430,430F, 431, SUS420J2 |

| Other Grade | 1215 / 12L14, 1144, |

| Supply Condition: | Solution Annealed, Soft Annealed, Solution Annealed, Quenched & Tempered, Ultrasonic Tested, Free from Surface Defects and Cracks, Free from Contamination |

| Length: | 2.0 2.5 meters & as per customer requirement |

| Finish: | Centreless Ground |

| Packing: | Each steel bar has the singal, and several will be bundled by weaving bag or as per requirement. |

| Specifications |

ISO 286-2 (Tolerance class according to finished condition)

| FinishedCondition | Tolerance class to ISO 286-2 | ||||||

| h6 | h7 | h8 | h9 | h10 | h11 | h12 | |

| Drawn | R | R | R,S,H | R,S,H | |||

| Turned | R | R | R | R | |||

| Ground | R | R | R | R | R | R | R |

| Polished | R | R | R | R | R | R | R |

| R = round, S = square, H = hexagon | |||||||

| ISO 286-2 (Tolerance Classes): |

| NominalDimension mm | Tolerance class to ISO 286-2 | ||||||

| h6 | h7 | h8 | h9 | h10 | h11 | h12 | |

| >1 to ≤ 3 | 0.006 | 0.010 | 0.014 | 0.025 | 0.040 | 0.060 | 0.100 |

| >3 to ≤ 6 | 0.008 | 0.012 | 0.018 | 0.030 | 0.048 | 0.075 | 0.120 |

| >6 to ≤ 10 | 0.009 | 0.015 | 0.022 | 0.036 | 0.058 | 0.090 | 0.150 |

| >10 to ≤ 18 | 0.011 | 0.018 | 0.027 | 0.043 | 0.070 | 0.110 | 0.180 |

| >18 to ≤ 30 | 0.013 | 0.021 | 0.033 | 0.052 | 0.084 | 0.130 | 0.210 |

| >30 to ≤ 50 | 0.016 | 0.025 | 0.039 | 0.062 | 0.100 | 0.160 | 0.250 |

| >50 to ≤ 80 | 0.019 | 0.030 | 0.046 | 0.074 | 0.120 | 0.190 | 0.300 |

| >80 to ≤ 120 | 0.022 | 0.035 | 0.054 | 0.087 | 0.140 | 0.220 | 0.350 |

| >120 to ≤ 180 | 0.025 | 0.040 | 0.063 | 0.100 | 0.160 | 0.250 | 0.400 |

| >180 to ≤ 200 | 0.029 | 0.046 | 0.072 | 0.115 | 0.185 | 0.290 | 0.460 |

The above deviation values are negatively disposed about the nominal dimension.

For example a 20mm nominal diameter having a tolerance class h9 is 20mm +0, -0.052mm or 19,948/20,000 mm

| Stainless steel grinding bar Straightness inspection: |

The straightness inspection of stainless steel grinding bars is a critical quality control process used to ensure the bars meet the required specifications for straightness. This inspection typically involves measuring the deviation of the bar from a perfectly straight line along its length. The procedure may use specialized equipment like laser sensors, dial indicators, or precision straight edges to assess the straightness of the bar. Any deviation beyond the allowable limit could affect the bar’s performance in subsequent machining or assembly processes. This inspection helps ensure the bars’ suitability for applications where precision and accurate alignment are essential, such as in the manufacturing of precision machinery or components.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

| SAKY STEEL’S Core Advantages: |

1.Straightness : 400MM≤0.01;

2.Diameter Tolerance ≤0.004;

3.Length: As customer required;

4.Magnetic: All production Degaussing Process;

5.Degree of finish: Be close to Ra 0.4;

| Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,