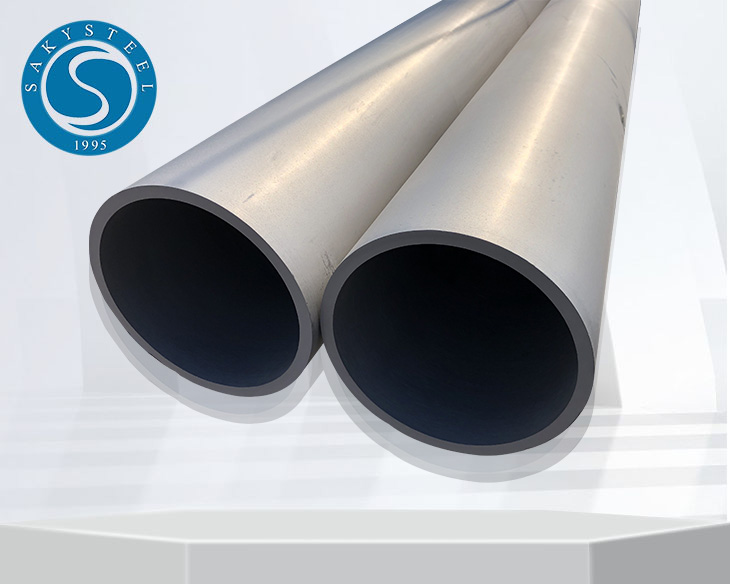

Stainless Steel 17–4 PH Pipe Tube

Short Description:

Explore our Stainless Steel 17–4 PH Pipe Tube selection – offering superior strength, corrosion resistance, and performance. Ideal for aerospace, marine, and chemical industries.

Stainless Steel Pipe Roughness Test:

Stainless Steel 17-4 PH Pipe Tube is a high-strength, corrosion-resistant material known for its excellent mechanical properties. As a precipitation-hardening stainless steel, it offers a combination of high tensile strength, good toughness, and superior resistance to oxidation and corrosive environments. Ideal for applications in aerospace, marine, chemical processing, and oil & gas industries, 17-4 PH pipe and tube maintain their strength even in high-temperature and high-pressure conditions, making them a versatile choice for demanding industrial applications.

Specifications of 17-4 PH Stainless Steel Tube:

| Grade | 304,316,321,904L,etc. |

| Standard | ASTM A/ASME SA213, A249, A269, A312, A358, A790 |

| Size | 1/8″NB TO 30″NB IN |

| Schedule | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless,Welded |

| Form | Rectangular, Round, Square, Capillary,Etc |

| Length | 5.8M,6M,12M & Required Length |

| End | Beveled End, Plain End, Treaded |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

17-4PH SS Pipe Chemical Composition:

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| 17-4PH | 0.07 | 1.0 | 1.0 | 0.03 | 0.04 | 15.0-17.5 | 3.0-5.0 | 3.0-5.0 |

Mechanical Properties of 17-4PH Stainless Steel Pipe:

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min |

| 17-4PH | Psi – 170000 | 6 | Psi – 140,000 |

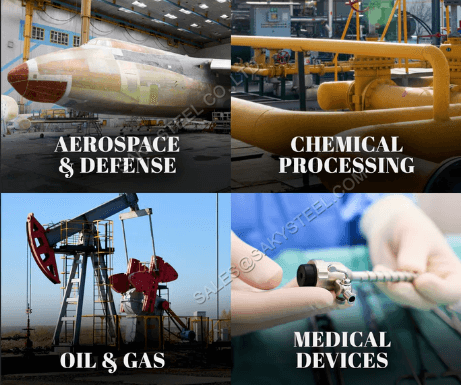

Application scenarios for stainless steel 17-4 PH pipe

1.Aerospace: Used in structural components and aircraft parts due to its high strength-to-weight ratio.

2.Oil and Gas: Employed in piping systems for its resistance to corrosion in harsh environments.

3.Chemical Processing: Utilized in valves, pumps, and other equipment where durability and resistance to chemicals are critical.

4.Marine Applications: Ideal for components exposed to seawater, as it withstands saltwater corrosion effectively.

5.Medical Devices: Used in surgical instruments and implants due to its biocompatibility and strength.

Advantages of stainless steel 17-4 PH pipe

1.High Strength: Offers excellent tensile and yield strength, making it suitable for demanding applications.

2.Corrosion Resistance: Provides good resistance to a variety of corrosive environments, enhancing durability.

3.Heat Treatable: Can be heat treated to achieve different mechanical properties, allowing for customization based on specific needs.

4.Versatility: Suitable for a wide range of applications, from aerospace to chemical processing.

5.Good Fabricability: Easily fabricated and welded, allowing for efficient manufacturing processes.

Why Choose Us?

1.With over 20 years of experience, our team of experts ensures top-notch quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

Quality Assurance:

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Large-scale test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Flaring Testing

8. Water-Jet Test

9. Penetrant Test

10. X-ray test

11. Intergranular Corrosion Testing

12. Impact analysis

13. Eddy current examining

14. Hydrostatic analysis

15. Metallography Experimental Test

Corrosion-resistant Steel Pipe Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,