Flange ea tšepe e sa hloekang

Tlhaloso e Khutšoanyane:

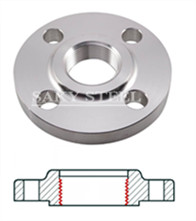

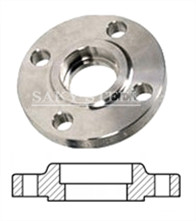

Saky steel ke moetsi, mofani wa thepa, le morekisi ya ntle ka ho fetisisa wa boleng bo botle haholo ba mabone a Stainless steel. Re tsebahala haholo ka lihlahisoa tse sebetsanang le lefats'e ka bophara 'me re fana ka li-SS flanges ho bareki ho latela litekanyetso le litlhoko tsa bona. Li-flanges tseo re fanang ka tsona ke selikalikoe se entsoeng kapa se entsoeng ka mokhoa o entsoeng bakeng sa ho hokahanya likarolo tsa liphaephe kapa mochine ofe kapa ofe o hlokang libaka tsa ho hokela tse mahareng. Li-flange li sebelisetsoa ho kopanya ka bolting kapa li kopantsoe le tsamaiso ea liphaephe ka ho roala kapa ho cheselletsa.

| Lintlha tse qaqileng tsa STšepe e se nang tšepe Li-flange: |

Slip-On WeldingFlangs Size1/2″ (15 NB) ho isa ho 48″ (1200NB)

Litlhaloso : ASTM A182 / ASME SA182

E tloaelehileng :ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, joalo-joalo.

Kereiti:304, 316, 321, 321Ti, 347, 347H, 904L, 2205, 2507

Sehlopha / Khatello :150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 joalo-joalo.

Mofuta oa sefahleho sa Flange:Sefahleho se Sephara (FF), Sefahleho se Phahameng (RF), Mofuta oa Ring Joint (RTJ)

| ASTM A182 / ASME SA182 Stainless Steel Flanges : |

|  |  |

| 316 Weld Neck Forged Flange | 316 Lap Joint Forged Flange | 316 Flange e Fetisitsoeng ea Khoele |

|  |  |

| 316 Sefofu se Foreditseng Flange | 316 Thellela holim'a Flange e Forged | 316 Socket Weld Forged Flange |

| Ke Hobane'ng ha U Re Khetha: |

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. e tiisetso ea ho fana ka karabo nakong ea lihora tse 24(hangata ka hora e tšoanang)

5. U ka fumana mefuta e meng ea li-stock, ho tsamaisoa ha leloala ka ho fokotsa nako ea tlhahiso.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

| Tiisetso ea Boleng (ho kenyeletsoa tse senyang le tse sa senyeheng) : |

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Teko e kholo

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Flaring Testing

8. Teko ea Jet ea Metsi

9. Penetrant Test

10. Tlhahlobo ea X-ray

11. Intergranular Corrosion Testing

12. Tlhahlobo ea phello

13. Eddy tlhahlobo ea hona joale

14. Tlhahlobo ea Hydrostatic

15. Metallography Teko ea Teko

| Sephutheloana: |

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,

E phuthetsoe

Mabokose a mabokose

Liphalete tsa lehong

Mabokose a lehong

Likerese tsa lehong

Lisebelisoa:

1. Mechini

2. Liphaephe tsa metsi

3. Tsa elektroniki

4. Meloko ea matla

5. Licheso tsa mocheso

6. Meriana ea meriana